19

q 10) Thread the wire into the pushrod. You can

thread the wire in further, or back it out, until the servo

arm aligns with the output shaft of the servo.

q 11) With the elevator and elevator servo in neu-

tral, install the servo arm onto the servo. The arm should

be positioned perpendicular to the servo and face the

middle of the fuselage. See photo # 38 below.

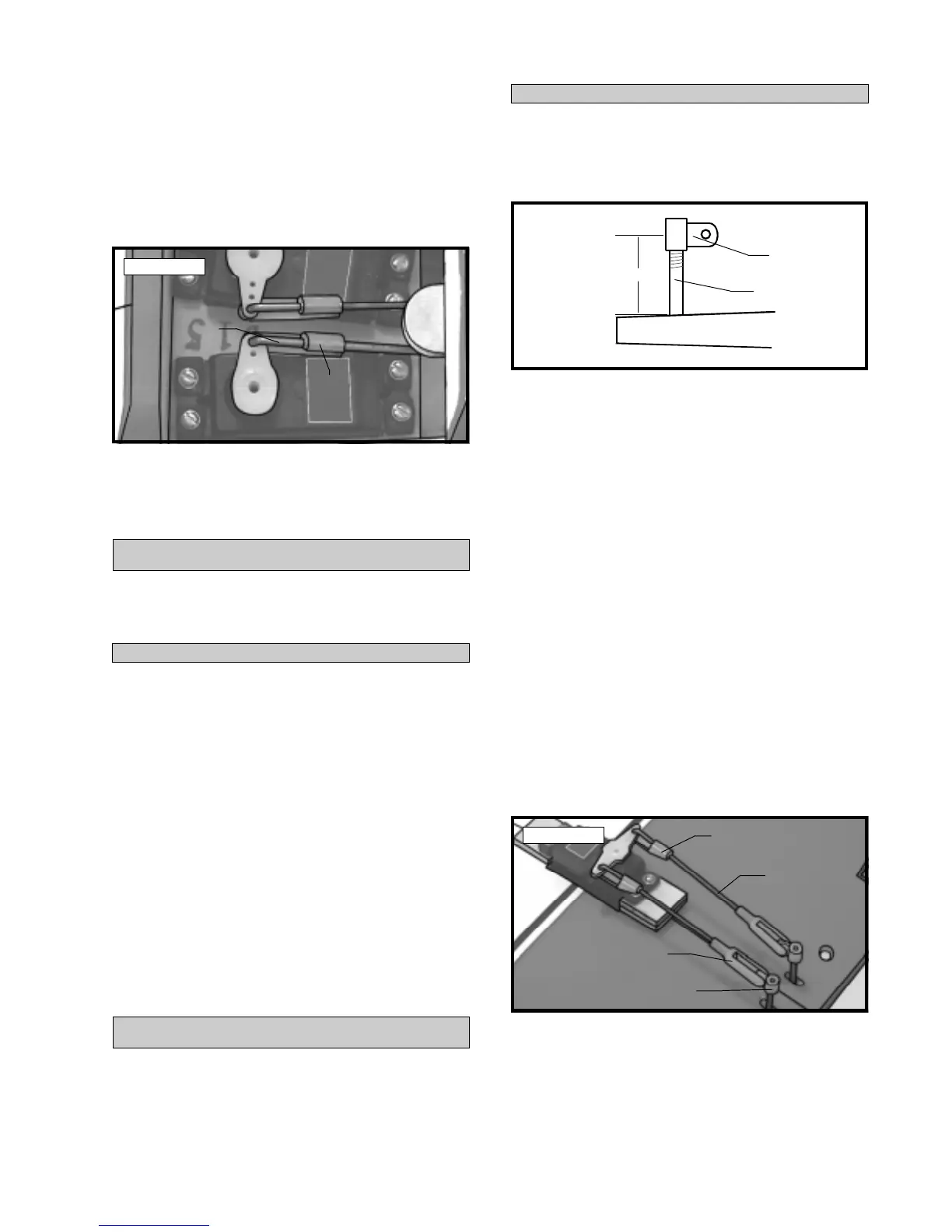

Photo # 39

q 12) Move the servo arm back and forth to test

for free movement. The pushrod should not bind in

any way. When satisfied with the movement, install

the servo arm retaining screw.

PARTS REQUIRED

q {1} Servo Hatch

q {1} 3mm x 15mm Wood Screw

INSTALLING THE SERVO HATCH

SERVO HATCH

q 1) Set the servo hatch in place on the bottom of

the fuselage. The preinstalled dowel should fully

engage the predrilled hole in the rear bulkhead.

q 2) Using a ruler and a pen locate and mark the

location of the hatch hold down screw. The hole

should be located directly in the centerline of the

hatch, 5/16” forward of the rear edge of the hatch.

q 3) With the hatch held firmly in place, drill a

5/64” pilot hole through the hatch and down through

the plywood hold down block in the fuselage.

q 4) Remove the hatch. Using a 1/8” drill bit, drill

out the pilot hole through the hatch only. Reinstall

the hatch and secure it in place using the 3mm x 15mm

wood screw. Do not overtighten the screw.

PARTS REQUIRED

q {2} Nylon Adjustable Control Horns

q {2} 2mm x 70mm Threaded Wire w/90º Bend

q {2} Nylon Clevis w/2mm I.D. Hole

q {2} Nylon Snap Keepers

INSTALLING THE AILERON LINKAGE

AILERON LINKAGE

q 1) Thread one nylon adjustable control horn

onto each aileron torque rod. Thread them on until

they are 5/8” above the top surface of the wing. See

figure # 8 below.

Figure # 8

q 2) Thread one nylon clevis at least 5/16” onto

each of the two 2mm x 70mm threaded rods with 90º

bends.

q 3) With the aileron servo centered, install one

dual-arm servo arm onto the servo. The arm should

be installed so it is parallel with the trailing edge of

the wing.

q 4) Use a couple of pieces of masking tape, taped

between the ailerons and the trailing edge of the wing,

to hold the two ailerons in neutral.

q 5) Snap the clevises onto the adjustable control

horns. With the servo arm and ailerons centered, push

the 90º bends down through the third hole out in each

side of the servo arm. Adjust the length of the wires

by turning the nylon clevises in or out until the cor-

rect length is achieved. Hold the wires in place using

two nylon snap keepers. See photo # 39 below.

Photo # 38

q 6) Move the servo arm back and forth to check

for free movement. The linkage should not bind in

any way. When satisfied with the movement, install

the servo arm retaining screw.

Snap

Keeper

Pushrod

Wire

Control Horn

Torque Rod

5/8”

Pushrod

Wire

Control

Horn

Clevis

Snap

Keeper

Loading...

Loading...