17

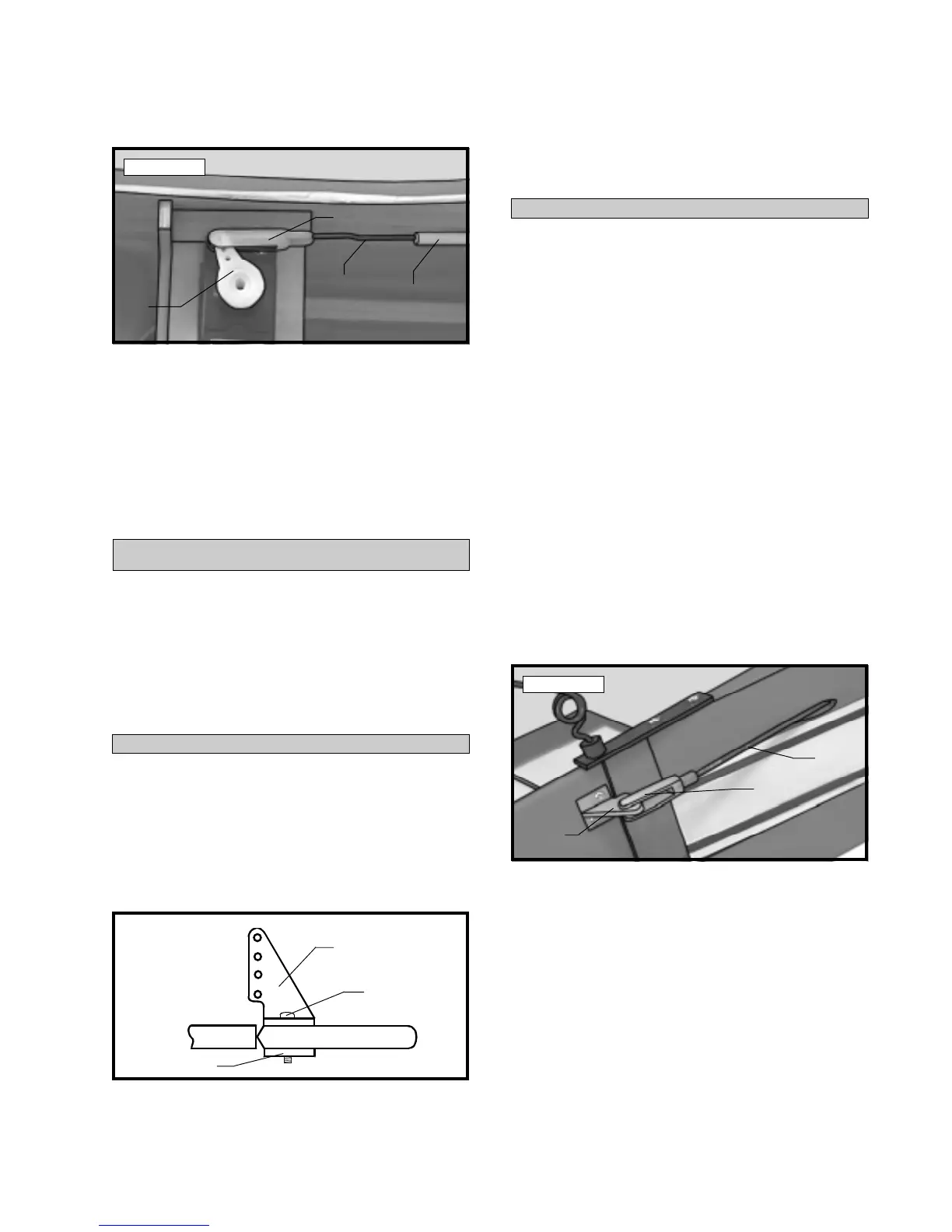

hole in the servo arm. You may need to make a slight

bend in the pushrod wire to allow it to align level

with the servo arm. See photo # 34 below.

Photo # 34

q 5) Test the movement of the throttle pushrod.

Full forward stick and full forward trim should result

in the carburetor barrel opening completely. Full back

stick and full forward trim should result in the ap-

proximate idle setting. Full back stick and full down

trim should result in the carburetor barrel closing fully.

q 6) When you are satisfied with the movement

of the pushrod, install the servo arm retaining screw.

PARTS REQUIRED

q {1} 4mm x 300mm Nylon Pushrod

q {1} 2mm x 62mm Threaded Wire w/90º Bend

q {1} 2mm x 100mm Threaded Straight Wire

q {1} Nylon Clevis w/2mm I.D. Hole

q {1} Nylon Snap Keeper

q {1} Nylon Control Horn w/Backplate

q {2} 2mm x 15mm Machine Screws

INSTALLING THE RUDDER CONTROL HORN

q 1) The centerline of the rudder control horn is

located on the left side of the rudder (looking from

behind) 9/16” up from the bottom of the rudder. Po-

sition the control horn so the clevis attachment holes

are directly in-line with the hinge line. The control

horn should also be parallel with the hinge line. See

figure # 6 below.

q 3) Mount the control horn to the rudder by in-

serting the 2mm x 15mm machine screws through the

control horn mounting base, through the rudder, and

into the backplate. Tighten the screws, but do not

overtighten them. You do not want to crush the wood.

INSTALLING THE RUDDER PUSHROD

q 4) Using a modeling knife, cut the 300mm ny-

lon pushrod to a length of 9-1/4”. Thread the 2mm x

100mm threaded wire into one end of the nylon push-

rod. For safety, thread the wire in no less than 5/16”.

q 5) Thread one nylon clevis onto the opposite end

of the 2mm x 100mm threaded wire. It should be

threaded no less than 5/16” onto the wire also.

q 6) Using a modeling knife remove the covering

from over the rudder pushrod exit slot. Looking from

the back of the airplane, the slot is located on the left

side of the fuselage, 3-1/8” forward of the rudder hinge

line and 1-1/4” below the horizontal stabilizer.

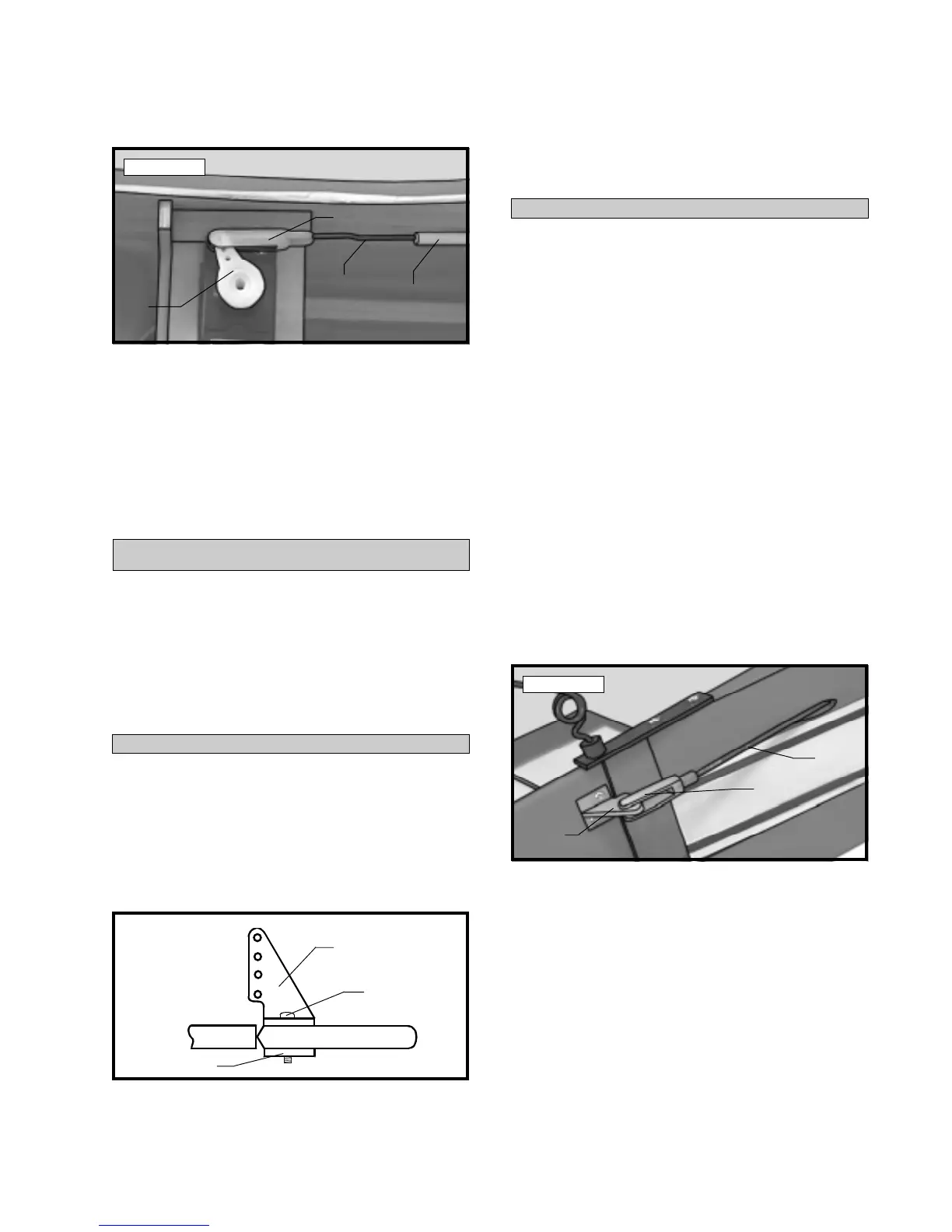

q 7) Insert the plain end of the nylon pushrod into

the pushrod housing from the back. Snap the clevis

onto the rudder control horn. Move the rudder back

and forth to ensure there is no binding. See photo #

35 below.

Photo # 35

q 8) Use a couple of pieces of masking tape to

hold the rudder in neutral.

q 9) Locate a servo arm, and using wire cutters,

remove all but one of the arms. Install the 90º bend

in the 2mm x 62mm wire into the third hole out from

center. Remove the excess servo arm using wire cut-

ters. Secure the wire in place using one nylon snap

keeper.

q 10) Thread the wire into the pushrod. You can

thread the wire in further, or back it out, until the servo

arm aligns with the output shaft of the servo.

RUDDER PUSHROD

Figure # 6

q 2) When satisfied with the alignment, use a

5/64” drill bit, and the control horn as a guide, and

drill the two mounting holes through the rudder.

Nylon

Pushrod

Pushrod

Wire

Nylon

Clevis

Servo

Arm

Clevis

Control

Horn

Pushrod

Wire

Control Horn

Backplate

Screw

Loading...

Loading...