21

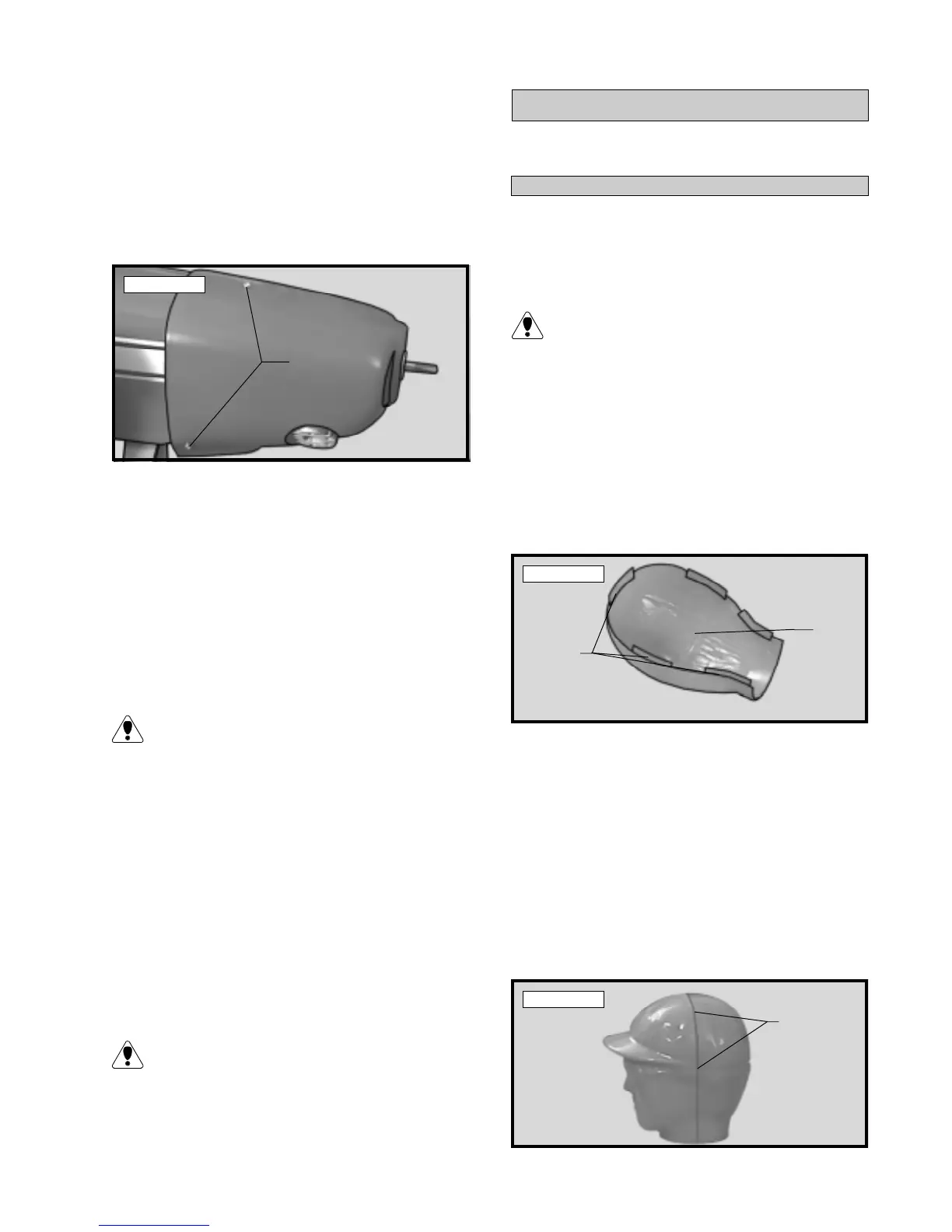

q 14) Apply a couple of drops of Kwik Bond Thin

C/A into each of the three cowl mounting holes. This

will harden the wood and keep the wood screws from

coming loose during flight.

q 15) Slide the cowl back onto the fuselage and

secure it in place using the three 3mm x 6mm wood

screws. See photo # 42 below.

Photo # 42

q 16) Locate the areas of the cowl that need to be

removed for access to the high and low speed needle

valves and muffler assembly.

q 17) Remove the cowl and make these cutouts

using a Dremel Tool with a cutting disc and sanding

drum attachment. Holes for the needle valves can be

cut using a drill bit. We highly suggest the use of a

Dubro Fuel Filler Valve to fuel the airplane. This

should be mounted to the cowl at this time also.

Because of the diameter of the cowl, it may be

necessary to use a needle valve extension for

the high speed needle valve. Make this out of suffi-

cient length 1.5mm wire and install it into the end of

the needle valve. Secure the wire in place by tighten-

ing the set screw in the side of the needle valve.

q 18) Install the muffler and connect the fuel and

pressure lines to the fuel tank, carburetor, muffler and

fuel filler valve.

q 19) Install the propeller and spinner assembly. The

spinner cone is held in place using two 2mm x 12mm

wood screws.

The propeller should not touch any part of the

spinner cone. If it does, use a sharp modeling

knife and carefully trim away the spinner cone where

the propeller comes in contact with it.

PARTS REQUIRED

q {1} Molded Plastic Pilot Head

PILOT ASSEMBLY

PILOT

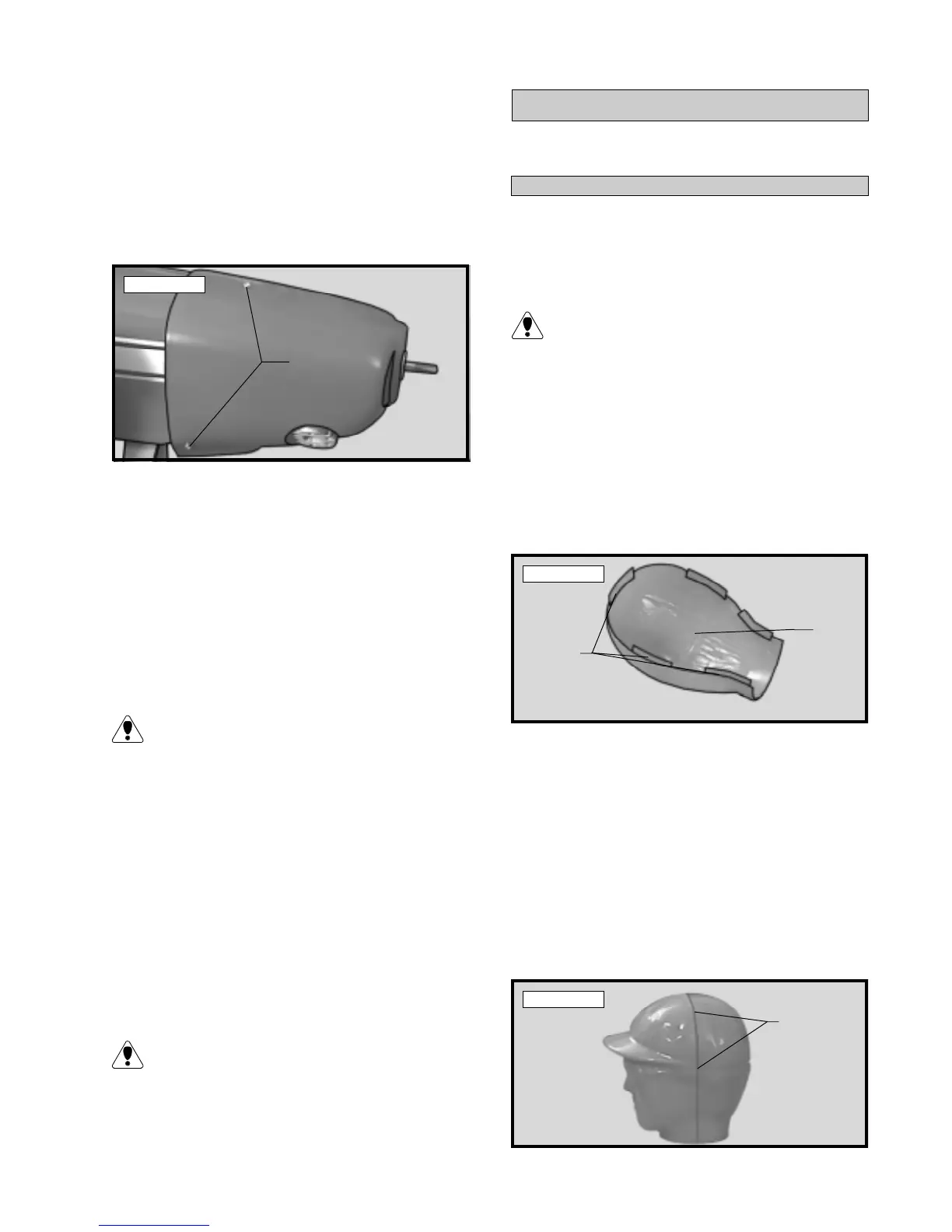

q 1) Using a modeling knife or Lexan Canopy

Scissors, trim off the rounded edges on the pilot head

halves. Use 220 grit sandpaper with a sanding block

and sand the edges smooth, flat and straight.

Pay careful attention to keeping the edges

straight. This will make joining the halves much

easier.

q 2) Using scissors, cut out small tabs about 1/8”

wide and 1/4” long from the excess plastic that was

trimmed off in the previous steps. Bend each of the

tabs at the middle into a shallow "V" shape.

q 3) Using thin C/A glue the tabs into only one

half of the pilot head at several locations along the

edges. See photo # 43 below.

Photo # 43

q 4) After the glue has completely cured, trial fit

the two halves together. Make any adjustments nec-

essary to get each half to fit as close as possible. When

satisfied with the fit, glue the halves together using

Kwik Bond Thin C/A. Work one tab at a time, hold-

ing the halves tightly together and applying one drop

of glue until the parts are completely glued together.

q 5) After the glue has completely cured, use 220

grit sandpaper and lightly sand the seams. If any gaps

are present they can be filled using Testors Contour

Putty. See photo # 44 below.

Photo # 44

Wood

Screws

Pilot

Head

Plastic

Tabs

Fill Seam

Loading...

Loading...