22 MCP15-500.7

Error Codes” section in the next column to clear the errors.

10. For furnace models with Digit 11=6 or 8, verify the furnace

control board and modulating valve is communicating

properly by adjusting the Fire Rate Input on the control

board from 10.0 to 2.0 with the up and down buttons.

• Thehighfiremanifoldpressuremaybeintherangeof

3.3" W.C to 3.5" W.C. at the 10.0 Fire Rate Input setting.

• Thelowfiremanifoldpressuremustnotgobelow

0.2" W.C. at the 2.0 Fire Rate Input setting. If the manifold

pressure drops below 0.2”W.C. or flame is lost, repeat

the "Check/Adjust Pressure at Combination Gas Valve"

section on the previous page and then repeat the “Low

Fire Setting” sequence described above.

11. Once the setting of the modulating valve has been

completed, replace the valve cover that was removed

earlier.

12. Move the field installed manual shut-off valve to the “OFF”

position, remove the manometer, and replace the 1/8" pipe

plug.

13. After the plug is in place, move the field installed manual

shut-off valve to the “ON” position and recheck the pipe

plug for gas leaks with soap solution.

14. For units with furnace model Digit 11=4, repeat the entire

process for the 2nd furnace.

Placing Furnace Control Into “Checkout Test Mode”

(Applies to furnace models with Digit 11=6 or 8)

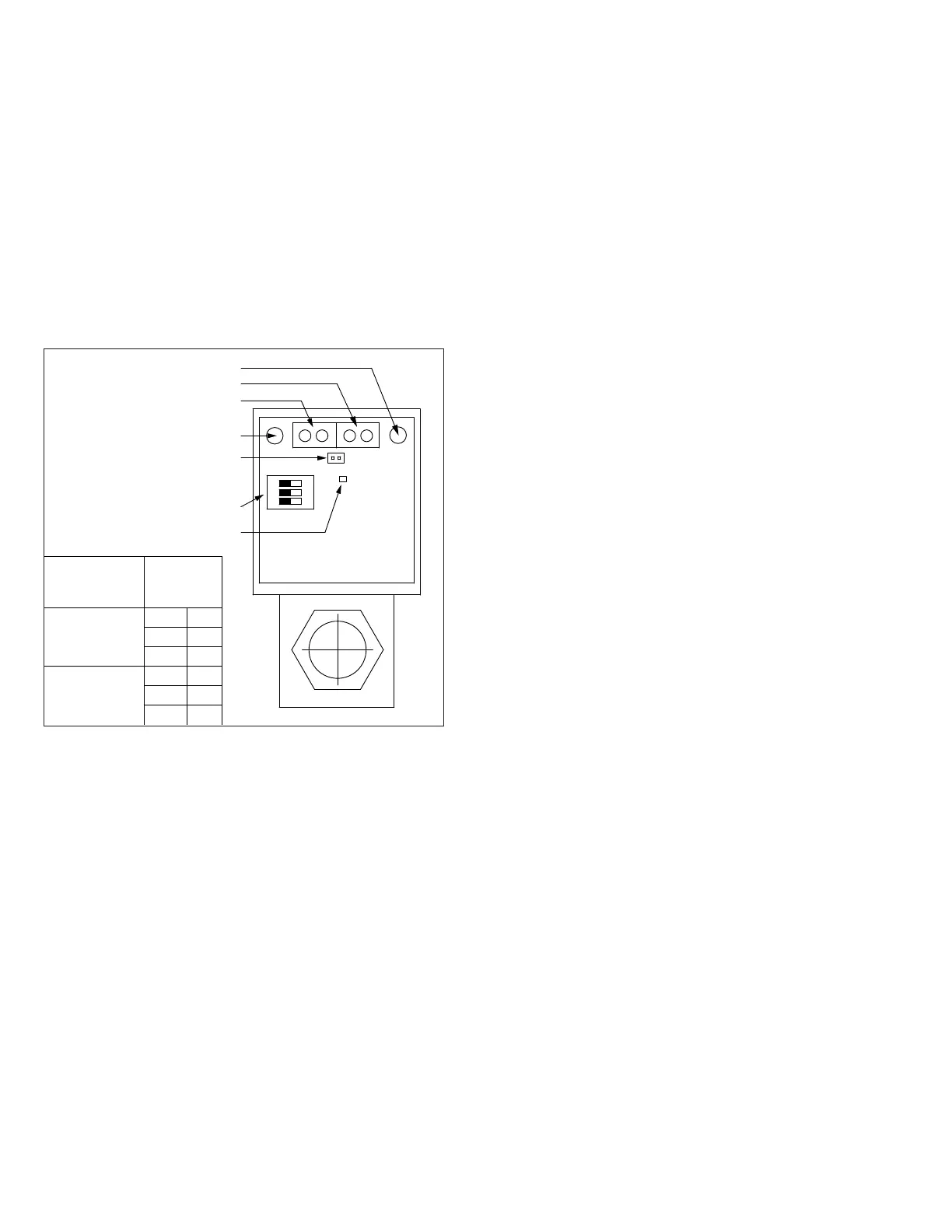

The furnace control board (Figure 23.1) has functionality to be

put it in a manual operation “Checkout Test Mode” for testing

purposes as noted in the previous sections for checking and

setting gas pressure. To enter that mode, perform the following

steps:

1. The Checkout Test mode is only available when the furnace

control board detects an “E09” error condition (No Firing

Rate Input). To accomplish this, temporarily disconnect wire

#804 from the furnace control board and create a call for

heat from the main Carel controller. Be sure to insulate the

end of the signal wire so it cannot cause a short.

2. Press the MODE button for at least 4 seconds until the LED

display changes to display “Lo9”.

3. Press the DOWN button briefly to change the display to

“tSt”, and then briefly press the MODE button to enter the

Checkout Test mode.

4. When the Checkout Test mode is entered, the control board

will initiate a normal ignition sequence with the Firing Rate

Input set to a simulated 10.0 VDC. The simulated Firing

Rate Input can be set to different 1.0 VDC step values from

10V to 2V. A 10V signal will give maximum fire rate while

a 2V signal will give the minimum fire rate. Once burner

ignition has been achieved and the control enters the RUN

mode, the normal runtime data parameters, including the

Firing Rate, will be continuously displayed on the furnace

control board LED indicators.

5. If a lockout error condition occurs, or the MODE button is

depressed for more than 4 seconds, or there is no push

button activity for 30 minutes, then the Checkout Test mode

will be exited.

Clearing Furnace Control Board Error Codes

1. Fault codes can be reviewed by pressing the MODE button

for at least 4 seconds until the LED display changes to

display “Lo9”. Refer to Figure 23.1 for location of buttons

and LED display.

2. Briefly press the MODE button again to review the fault

codes. Up to 15 fault codes are stored and can be reviewed

START-UP PROCEDURE - CONTINUED

8. Adjust the Low Fire Setting as follows:

a. For units with furnace model Digit 11=6 or 8, place

the furnace control into the “Checkout Test Mode” as

instructed in the next section and set the Fire Rate Input

to 2.0.

b. Press and hold Button #2 on the modulating valve until

the LED light blinks red, then release.

c. With the valve now in the low fire setting mode, confirm

or adjust the low fire manifold pressure to be no less than

the minimum shown on the furnace serial plate in the box

called “Min. Manifold Pressure”. If the pressure needs to

be adjusted:

Press or hold Button #1 to increase gas flow and press

Button #2 to decrease gas flow. It is best to push

and release button #2 to single step the valve to the

minimum manifold pressure. Pressing and holding the

button is likely to cause the valve to close too far and

lose flame.

d. Save the setting by simultaneously holding Buttons #1

and #2 until the LED turns OFF. If this is not performed

within 5 minutes, the control will default to the previously

saved settings and return to normal operating mode.

9. For furnace models with Digit 11=6 or 8, if no errors or

alerts were recorded by the board (these will be on the

3 LED displays as an “A” or “E” followed by a number),

proceed to the next step. If any alerts or errors were logged

by the board, refer to the “Clearing Furnace Control Board

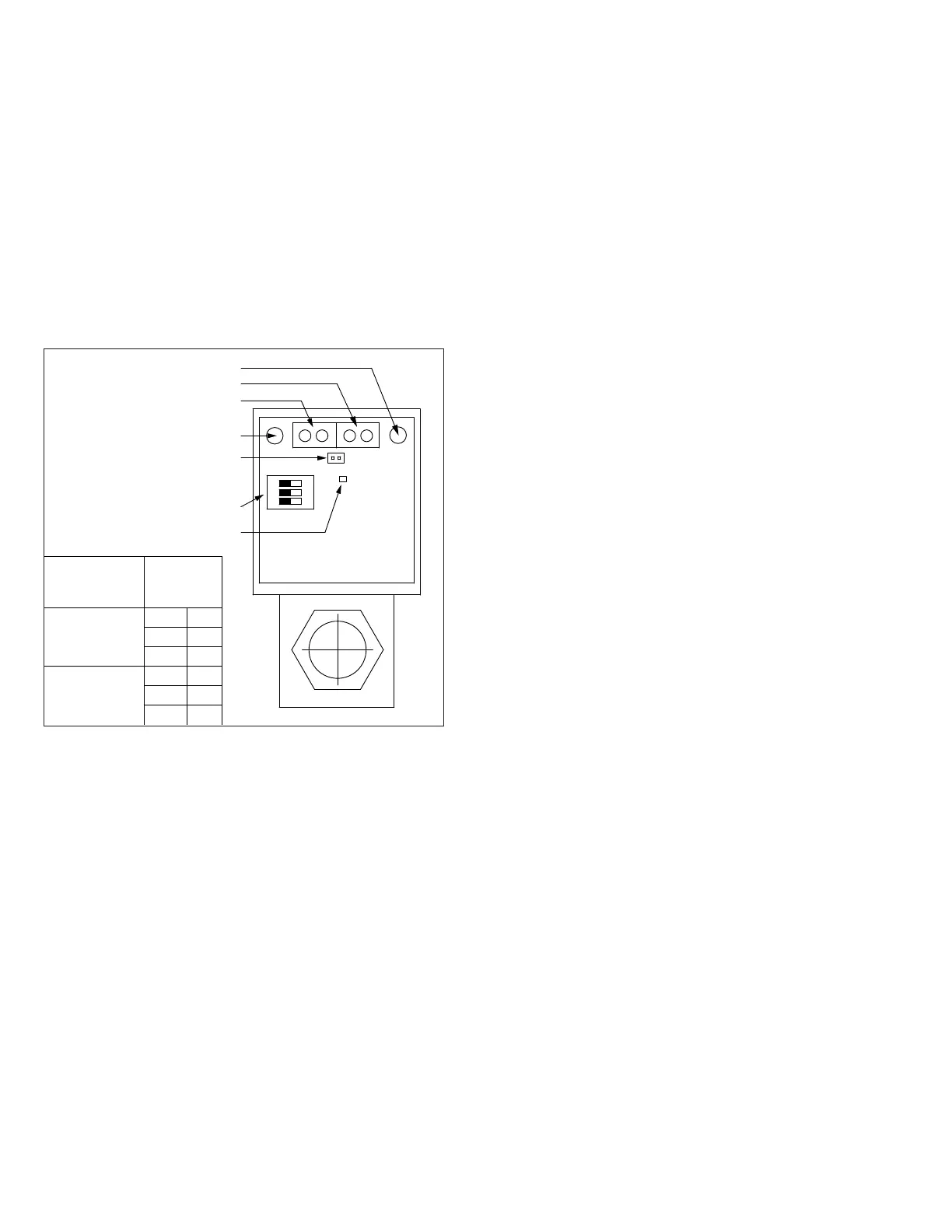

Figure 22.1 - Maxitrol Modulating Valve Adjustments

ON

1 2 3

1 2

3 4

BUTTON #1

BUTTON #2

CONTROL SIGNAL

WIRING TERMINALS

SUPPLY POWER

WIRING TERMINALS

POSITION FEEDBACK

WIRING TERMINALS

(ONLY ON UNITS WITH FURNACE

MODEL DIGIT 10=6, 7, OR 8)

DIP SWITCHES

(SEE TABLE FOR SETTINGS)

LED INDICATOR

Furnace Model

Digit 11

(Capacity Control)

DIP Switch

Settings

4

SW #1 OFF

SW #2 OFF

SW #3 OFF

6 or 8

SW #1 OFF

SW #2 ON

SW #3 OFF

or adjust the high fire manifold pressure to be 3.5" W.C.

If the pressure needs to be adjusted, press or hold

Button #1 to increase gas flow and press or hold Button

#2 to decrease gas flow.

e. If 3.5" W.C. cannot be attained, recheck the inlet gas

pressure as described previously. After addressing any

issues, if 3.5" W.C. still cannot be attained, step the

valve closed using button #2 to the point where manifold

pressure begins to be impacted. If the pressure at that

point is less than 3.3" W.C., corrective action is required.

f. Save the setting by simultaneously holding Buttons #1

and #2 until the LED turns OFF. If this is not performed

within 5 minutes, the control will default to the previously

saved settings and return to normal operating mode.

Loading...

Loading...