23MCP15-500.7

START-UP PROCEDURE - CONTINUED

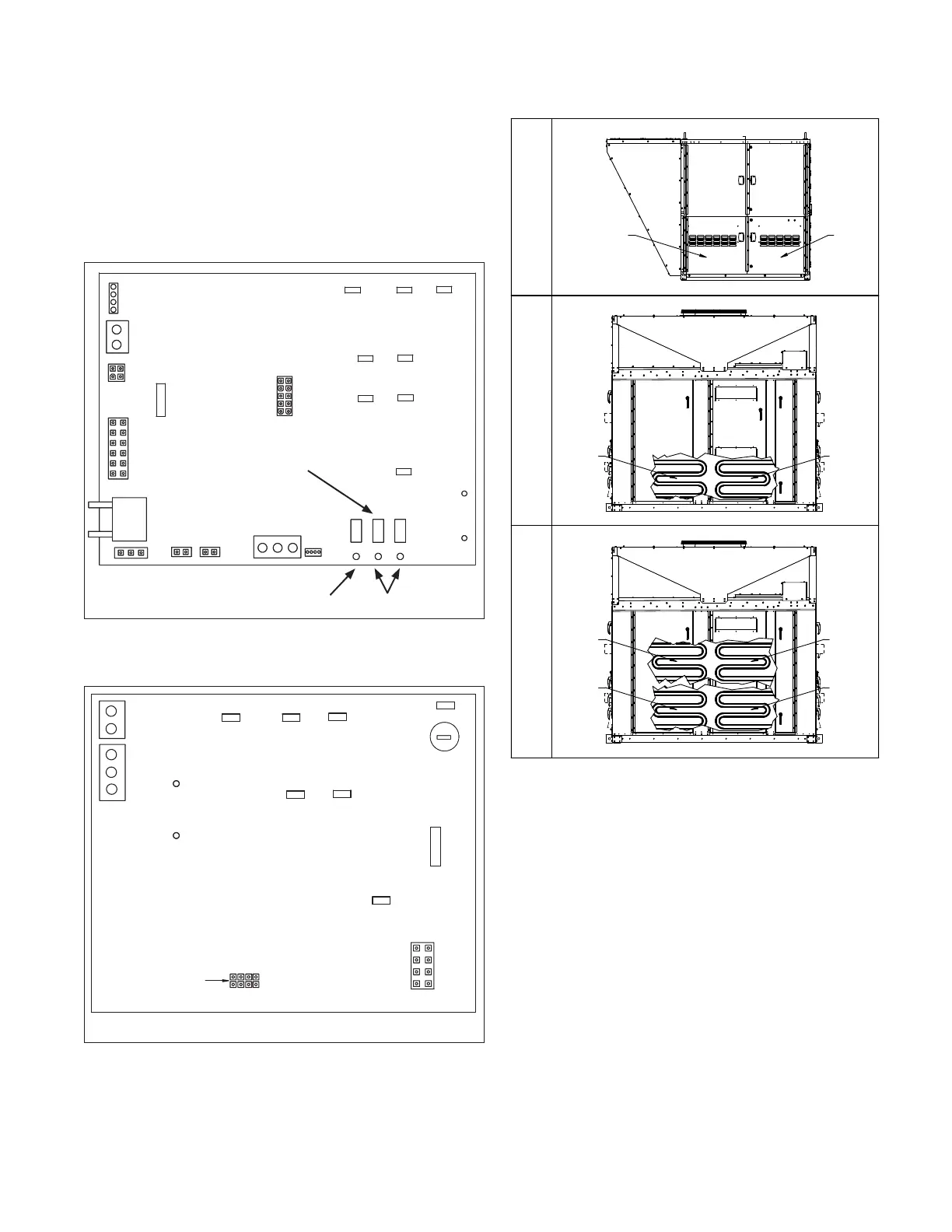

Figure 23.1 - Furnace Master Control Board

(Furnace models with Digit 11=6 or 8 only)

FLAME VOLT

1.0VDC=1MCIROAMP

+

_

FLAME ROD

IND-L2

IND-L1

L2

L1

FUSE

3

W

R

VB1201

CONTROL BOARD

IND-L2

IND-L1

GND

A

B

GND

ABCD

SLAVE

GND

WHITE

JUMPER SETTING MUST

MATCH FURNACE SLAV E

DESIGNATION. 1

Figure 23.2 - Furnace Slave Control Board

(Furnace models with Digit 11=8)j

NOTE: FOR ACTUAL WIRING TO THE FURNACE CONTROL BOARD, PLEASE REFER TO THE

WIRING DIAGRAM LOCATED IN THE FURNACE CONTROL COMPARTMENT.

j This applies to C- and D-Cabinet sized units with furnace model Digit 11=8.

Refer to Figure 23.3 for identifying which furnace is the Master and which

furnace(s) are the Slave(s).

J13

J8

J12

J6

J7

J4

+

_

-

+

W

R

+

_

FLAME ROD

L2

L1

ALARM

OUTPUT

FUSE

3

J13

J8

J12

J6

J7

J4

-

+

VB1200

CONTROL BOARD

DOWNUPMODE

+

_

PRESSURE

SENSOR

FLAME VOLT

1.0VDC=1MCIROAMP

+

_

ID

PLUG

AUX-L2

AUX-L1

IND-L2

IND-L1

L2

L1

GND

BA

GND

NOTE: FOR ACTUAL WIRING TO THE FURNACE CONTROL

BOARD, PLEASE REFER TO THE WIRING DIAGRAM LOCATED

IN THE FURNACE CONTROL COMPARTMENT.

MODE BUTTON

7-SEGMENT

LED DISPLAY

UP/DOWN BUTTONS

by pressing the UP or DOWN buttons. Codes will be

displayed followed by the number of days since the fault

was detected.

3. To clear the fault codes from memory, press the DOWN

button until “CLr” is displayed. Press and hold the MODE

button to clear the memory. The board will then revert to

normal operation.

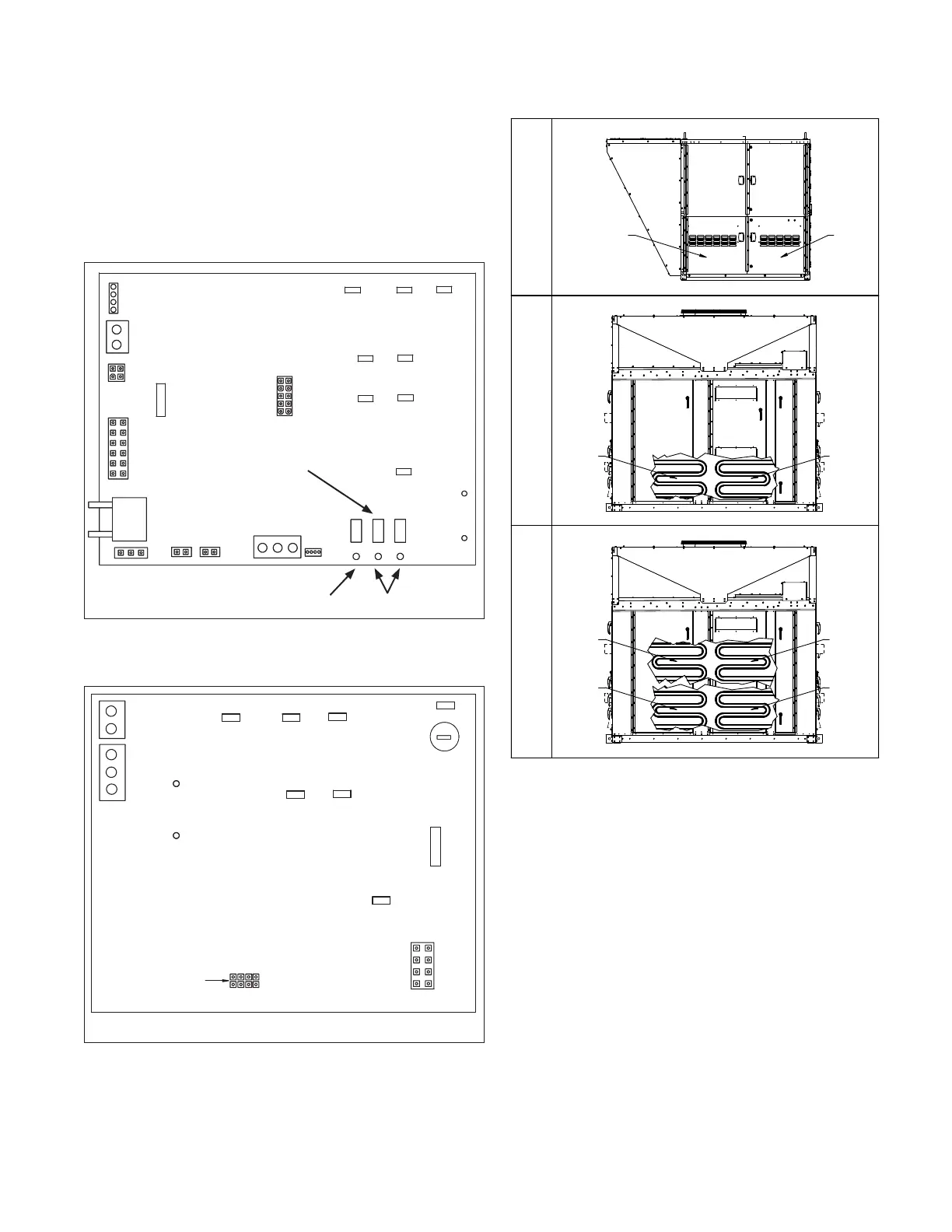

D-CABINET SIZE UNIT

(OVER 800,000 BTU/HR)

D-CABINET SIZE UNIT

(UP TO 800,000 BTU/HR)

C-CABINET SIZE UNIT

(ALL GAS HEAT SIZES)

SLAVE A

SLAVE C

SLAVE B

MASTER

SLAVE A MASTER

SLAVE A MASTER

Final Check

1. Operate furnace (all furnaces for units with multiple heat

exchangers) at high fire and verify that gas pressure to the

INLET of the combination gas control valve is maintained

at 6”-7” W.C. If the pressure cannot be maintained at 6”-7”

W.C. while operating at high fire, the gas supply system is

undersized and must be corrected and the entire check and

adjustment of gas pressures section must be repeated.

2. Once all gas pressures have been checked and are at

the proper settings, shut the unit down and move the field

installed manual shut-off value to the “OFF” position.

3. Remove all testing equipment and replace any hardware

(plugs, covers, etc.). For furnace models with Digit 11=6,

replace wire #804 that was temporarily removed when the

control was placed in the “Checkout Test Mode”.

4. Close the unit access doors.

Figure 23.3 - Furnace Master/Slave Locations

k Furnace locations are shown for reference, not the location of the furnace

controls. Refer to the figures on pages 25 through 27 for controls location.

Loading...

Loading...