Maintenance

January 2019 6-19

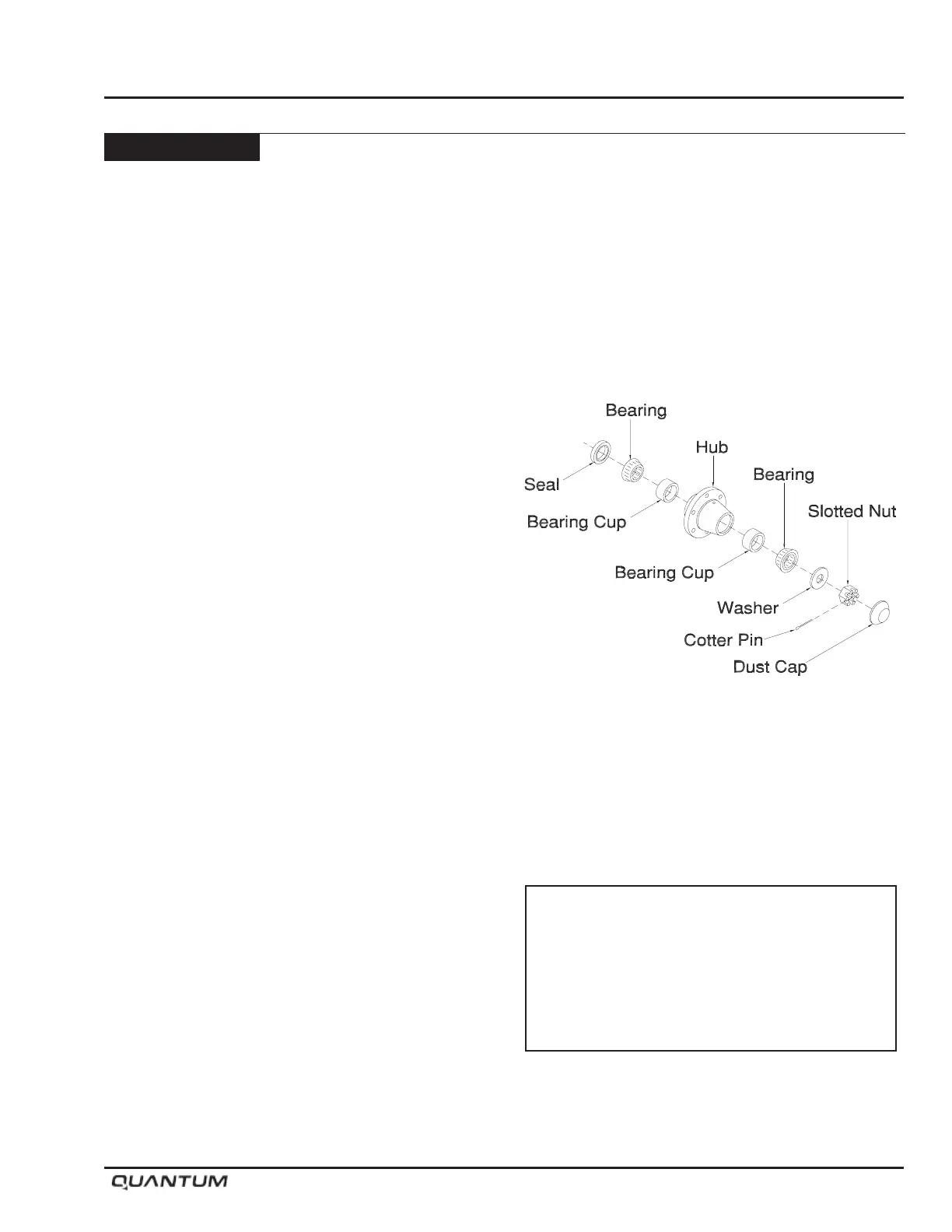

Wheel Bearings

Implement Hub

• Position implement in eld position.

• Shut tractor off, remove key, and engage park brake.

• Block wheel on tractor.

• Raise the implement wheel enough to clear the

surface.

• Securely block implement frame.

• Remove wheel from hub.

• Remove the dust cap, cotter pin, and the slotted nut

and washer.

• Be careful when pulling the hub off as not to drop

the outer bearing.

• Clean spindle and bearing components with solvent.

• Inspect for wear on bearings, spindle and cups,

replace parts as required.

• Do not reuse old seals. Use only new seals when

assembling.

• Pack inner hub with bearing grease.

• Be sure bearing and cup are dry and clean.

• Work grease into the bearing rollers, until each part

of the bearing is completely full of grease.

• Install inner bearing and cup rst, then press new

seals in place.

• Place hub on spindle.

• Install outer bearing, washer and slotted nut.

• Tighten nut while turning the wheel until a slight drag

is felt.

• Back nut off one slot and install a cotter pin. Bend

cotter pin up around nut.

• Pack grease inside the dust cap and tap into position.

Important

Check wheel bearings for play every

5,000 acres (2,000 hectares)

or yearly, which ever occurs first.

Tighten as required.

Loading...

Loading...