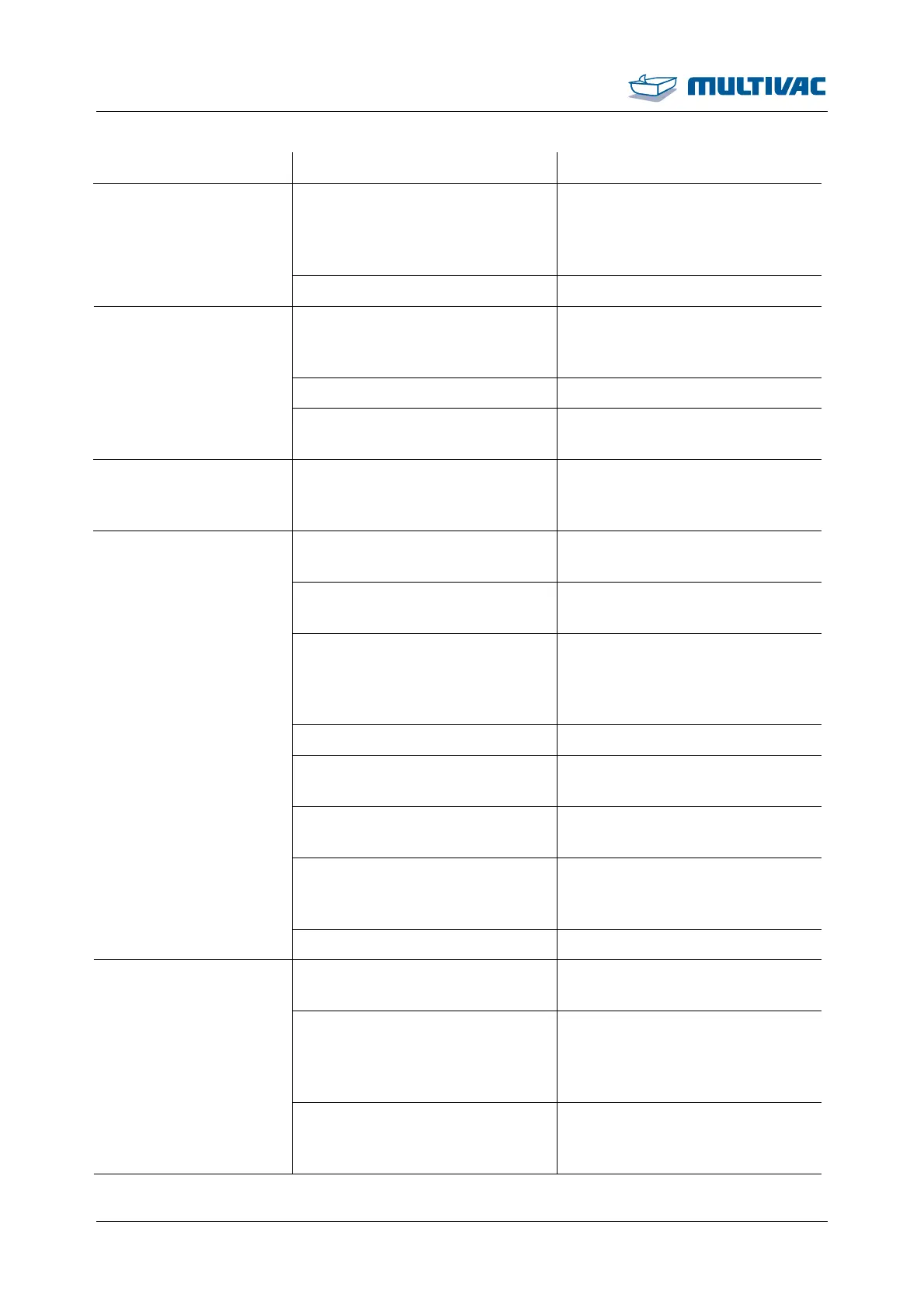

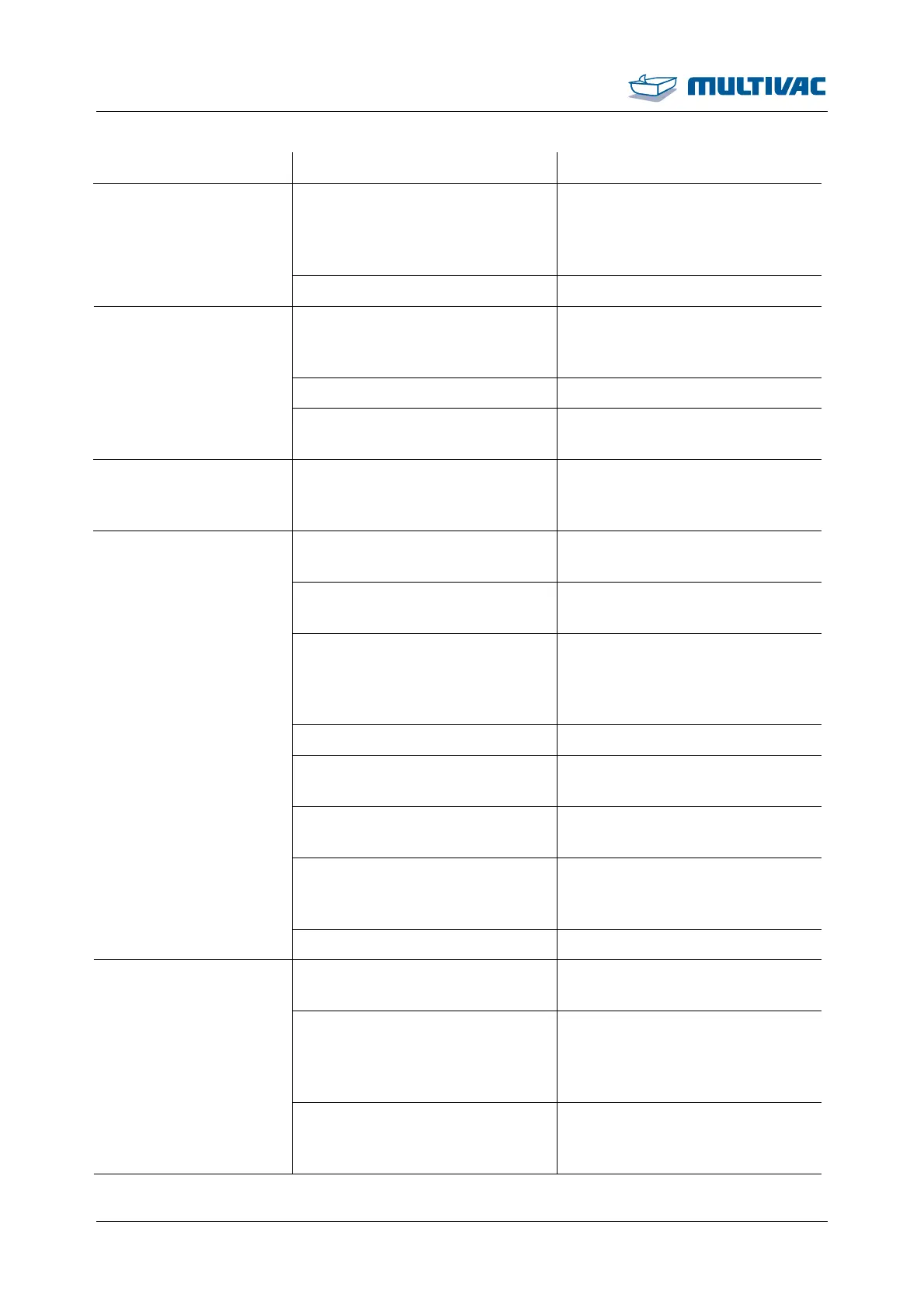

Troubleshooting

Faults without diagnostic message

76 03.06.2014

Symptom Cause Solution

• Ambient temperature too low. • Operate the machine only at

permissible ambient tempera-

ture, see "Technical Specifica-

tions".

• Vacuum pump defective. • Notify the service.

• Chamber lid pressed closed

too briefly.

• Press the chamber lid shut

more evenly, more firmly and

for longer.

• Chamber lid gasket is dirty. • Clean the chamber lid gasket.

Chamber lid does not

remain closed despite

pump running.

• Chamber lid gasket is dam-

aged.

• Change chamber lid gasket.

The vacuum pump only

runs for a very short

period.

• Evacuation time is set incor-

rectly.

• Increase evacuation time.

• Evacuation time is set incor-

rectly.

• Increase evacuation time.

• Gas flushing time is set incor-

rectly.

• Reduce the gas flushing time.

• Pouch neck is clamped by

chamber lid.

• Insert the film pouch so that

the pouch neck lies within the

chamber. Cut off the pouch

neck if necessary.

• Chamber lid gasket is dirty. • Clean the chamber lid gasket.

• Insufficient oil quantity or oil in

the vacuum pump is too old.

• Refill or replace oil.

• Chamber lid gasket is dam-

aged.

• Change chamber lid gasket.

• Moist or liquid products give

off steam during the evacua-

tion process.

• Abort the evacuation process

with the <Stop> key in case

the chamber lid mists up.

Poor vacuum in the

pack.

• Evacuation system is leaking. • Notify the service.

• Sealing time is set incorrectly. • Increase the sealing time in

small increments.

• Pouch neck is clamped by

chamber lid.

• Insert the film pouch so that

the pouch neck lies within the

chamber. Cut off the pouch

neck if necessary.

Pack is leaking.

• Seal seam is dirty. • Keep the inside of the film

pouch in the area of the seal

seam clean.

Loading...

Loading...