4VAL Operating & Maintenance Manual Version 1.1 © Newman Labelling Systems Ltd Page 30 of 56

SECTION 4 SET-UP PROCEDURE

4.1 INITIAL SET-UP PROCEDURE

Machines are normally despatched set for one of the label/container combinations

ordered, but exported machines may have had the labelling head table and the control

box lowered for transport purposes.

It is desirable to have the first production run on the set combination as this will

minimise the risk of mistakes and give all personnel an opportunity of becoming familiar

with the machine before a complete change-over is undertaken.

The following procedure assumes that the machine is to be run on the delivery set-up but

it is recommended that the sections describing the relevant controls be read prior to

making any adjustments.

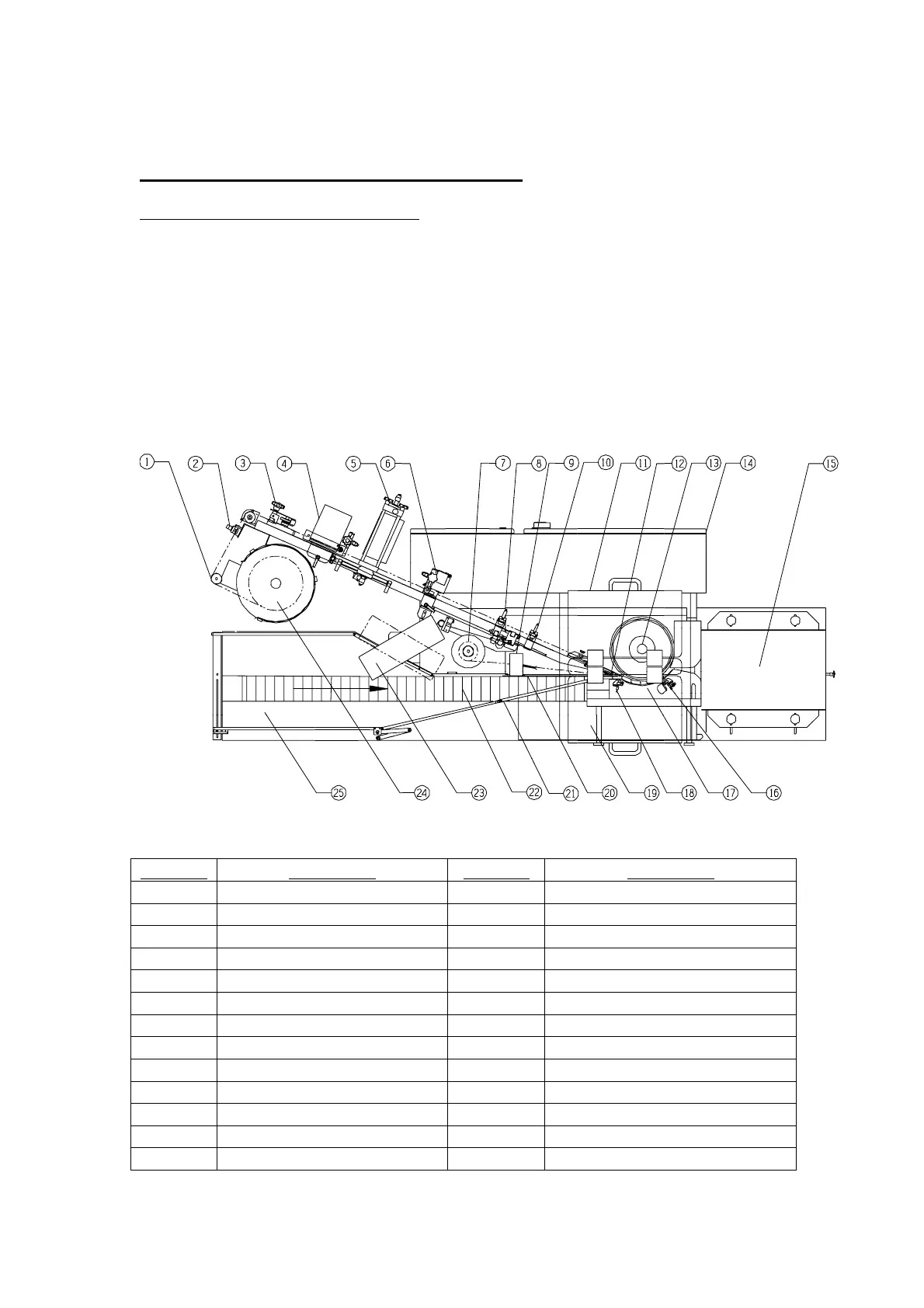

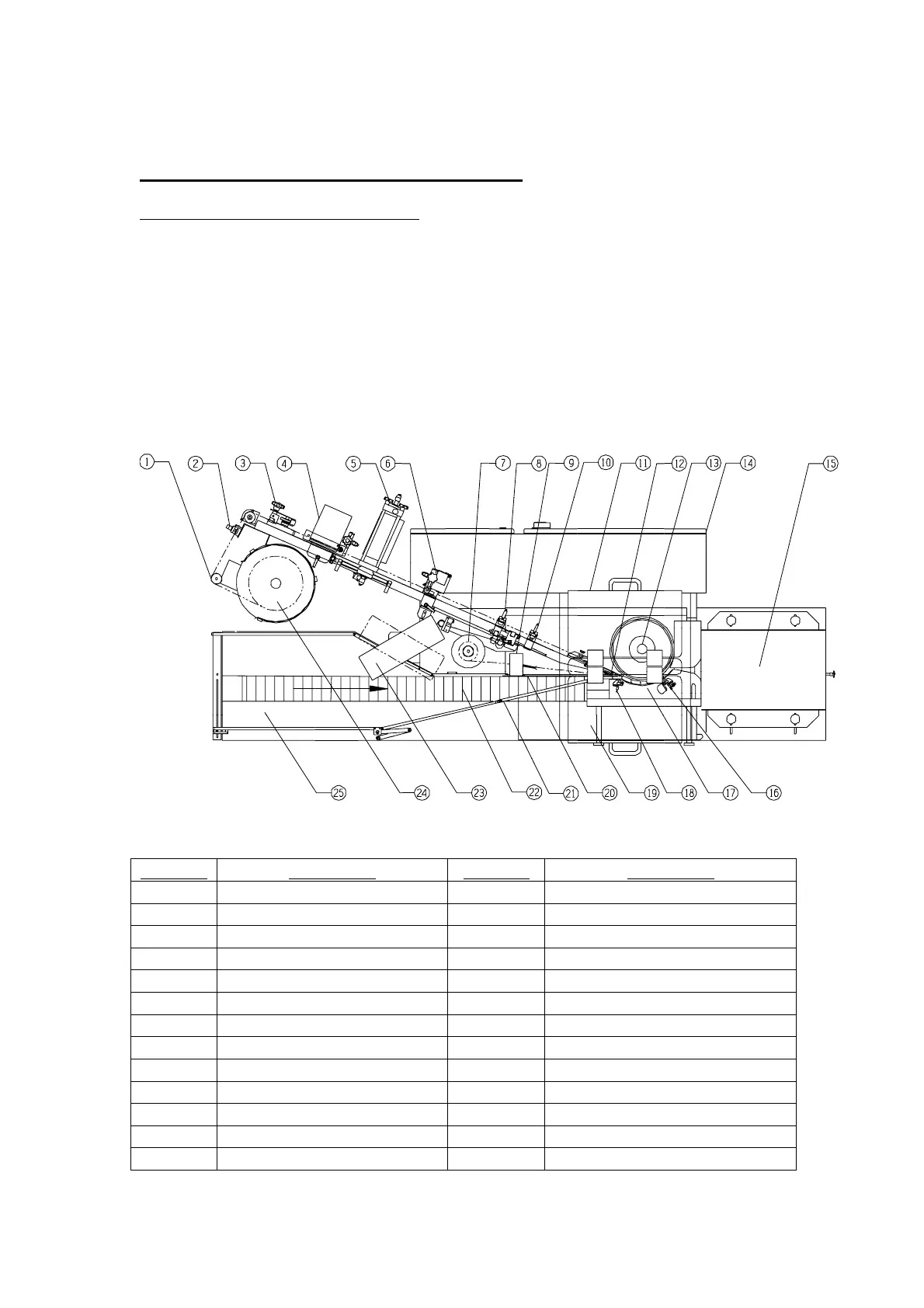

4VAL Layout Drawing (29916a)

Item No.

Description Item No. Description

1 Dancing arm 2 Label runout sensor

3 Web tensioner 4 Bar code reader

5 Coder 6 Overprint detector

7 Waste web take up 8 Label sensor 1

9 Label feed rollers 10 Label sensor 2

11 Guard rear door 12 Stripper plate

13 Applicator drum 14 Electrical cabinet

15 Outfeed tray table 16 Missing label sensor

17 Presser pad 18 Product sensor

19 Guard front door 20 Fixed guide rail

21 Adjustable guide rail 22 Conveyor

23 Operator console 24 Label reel holder

25 Tray unload area

Loading...

Loading...