4VAL Operating & Maintenance Manual Version 1.1 © Newman Labelling Systems Ltd Page 50 of 56

SECTION 6 FAULT DIAGNOSIS

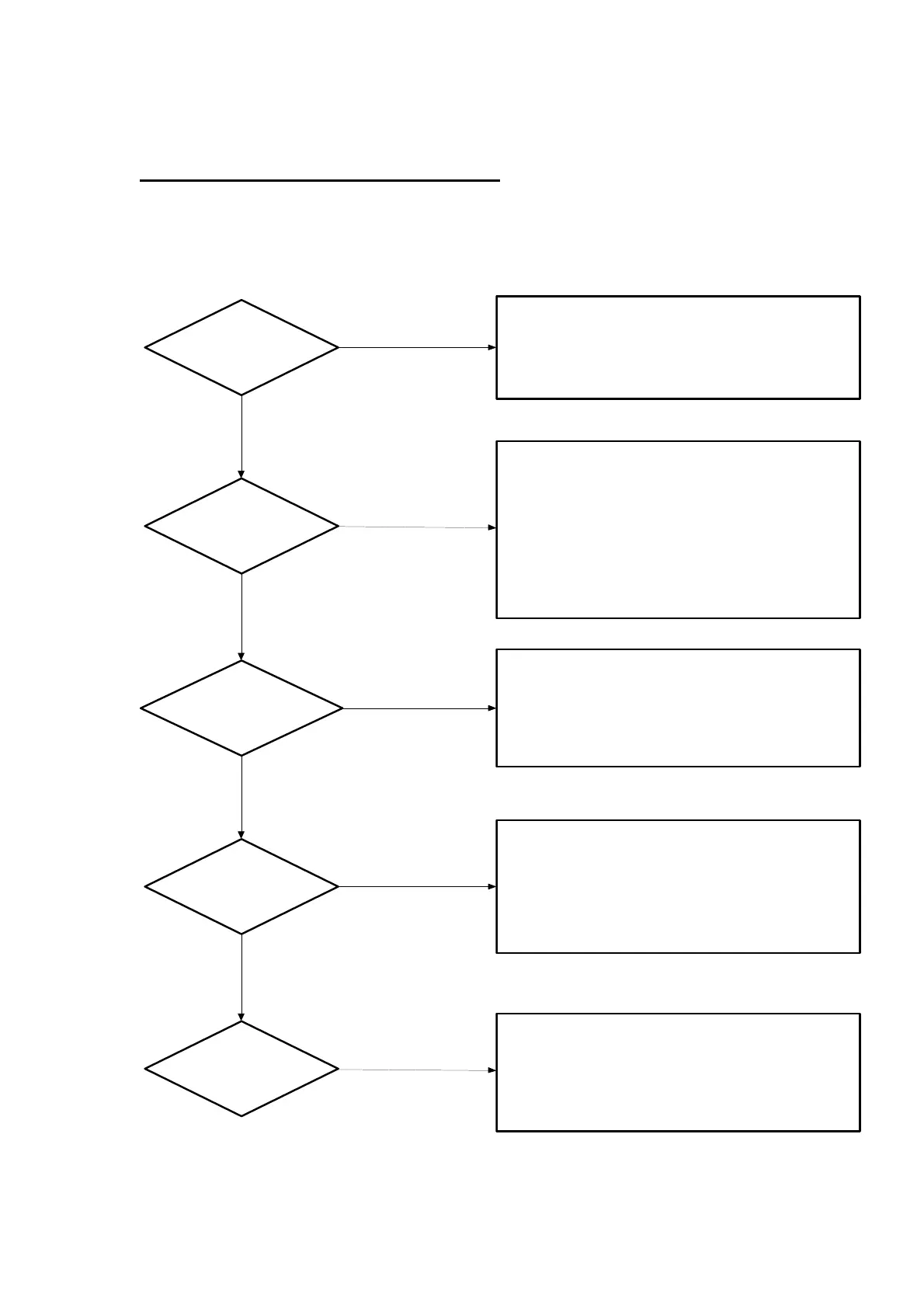

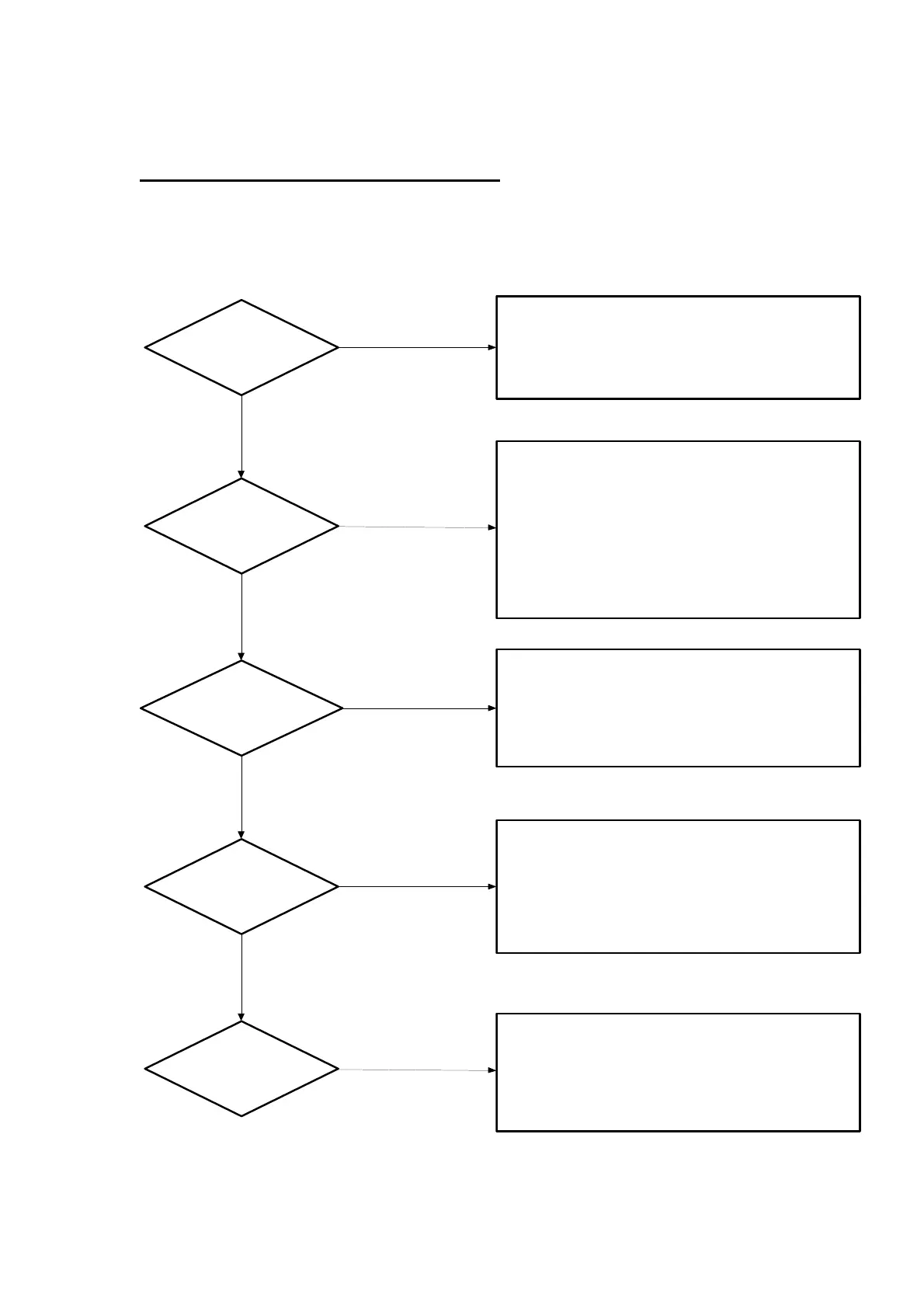

4VAL FAULT DIAGNOSIS - LABELLING

NO

CONTAINERS

FEEDING OK?

CHECK:

GUIDE RAILS ARE SET CORRECTLY

PRESSER PAD IS SET CORRECTLY

PRESSER PAD IS SECURE

CONVEYOR IS CLEAN

CONTAINERS ARE CLEAN

YES

YES

NO

YES

NO

YES

YES

NO

LABEL

FEED OK?

CHECK:

LABEL UNW IND TABLE ROTATING SMOOTHLY

ROLLERS AND POSTS ARE SECURE AND CLEAN

W EB GUIDE COLLARS ARE SET CORRECTLY

TENSIONER IS CLEAN AND NOT TOO TIGHT

STRIPPER PLATE IS CLEAN AND SECURE

SERRATED ROLLERS ARE CLEAN

SERRATED ROLLER GAP IS CORRECT

W EB REW IND CLUTCH IS SLIPPING

CODER DW ELL IS NOT TOO LONG

LABEL SENSORS SET CORRECTLY

LABEL

APPLICATION

O K?

CHECK:

ALL ITEMS ABOVE IN "LABEL FEED OK?"

PRODUCT SENSOR SET CORRECTLY

GRIP ON CONTAINER BETW EEN APPLICATOR AND

PRESSER IS CORRECT

STRIPPER PLATE IS SQUARE TO CONTAINER

LABEL ARM ALIGNMENT IS CORRECT

GAP IS CORRECT BETW EEN APPLICATOR AND

STRIPPER PLATE

PRINT

REGISTRATION

O K?

CHECK:

ALL ITEMS ABOVE IN "LABEL FEED OK?"

CONTAINER NOT PULLING LABEL OFF THE W EB

W EB IS UNDER TENSION DURING LABEL FIRE CYCLE

CODER FUNCTION AND SETTINGS

W EB FOR STRETCHING

W EB

BREAKING?

CHECK:

CODER DW ELL TIME IS NOT TOO LONG

SERRATED ROLLERS NOT TOO TIGHT AND CUTTING WEB

W EB IS UNDER TENSION ALL THE TIME DURING LABEL

FIRE CYCLE

W EB TENSION ALONG LABEL ARM

W EB FOR DIECUTTING

Loading...

Loading...