7. Care and Maintenance

Regular maintenance is essential for keeping your XiP printer operating successfully.

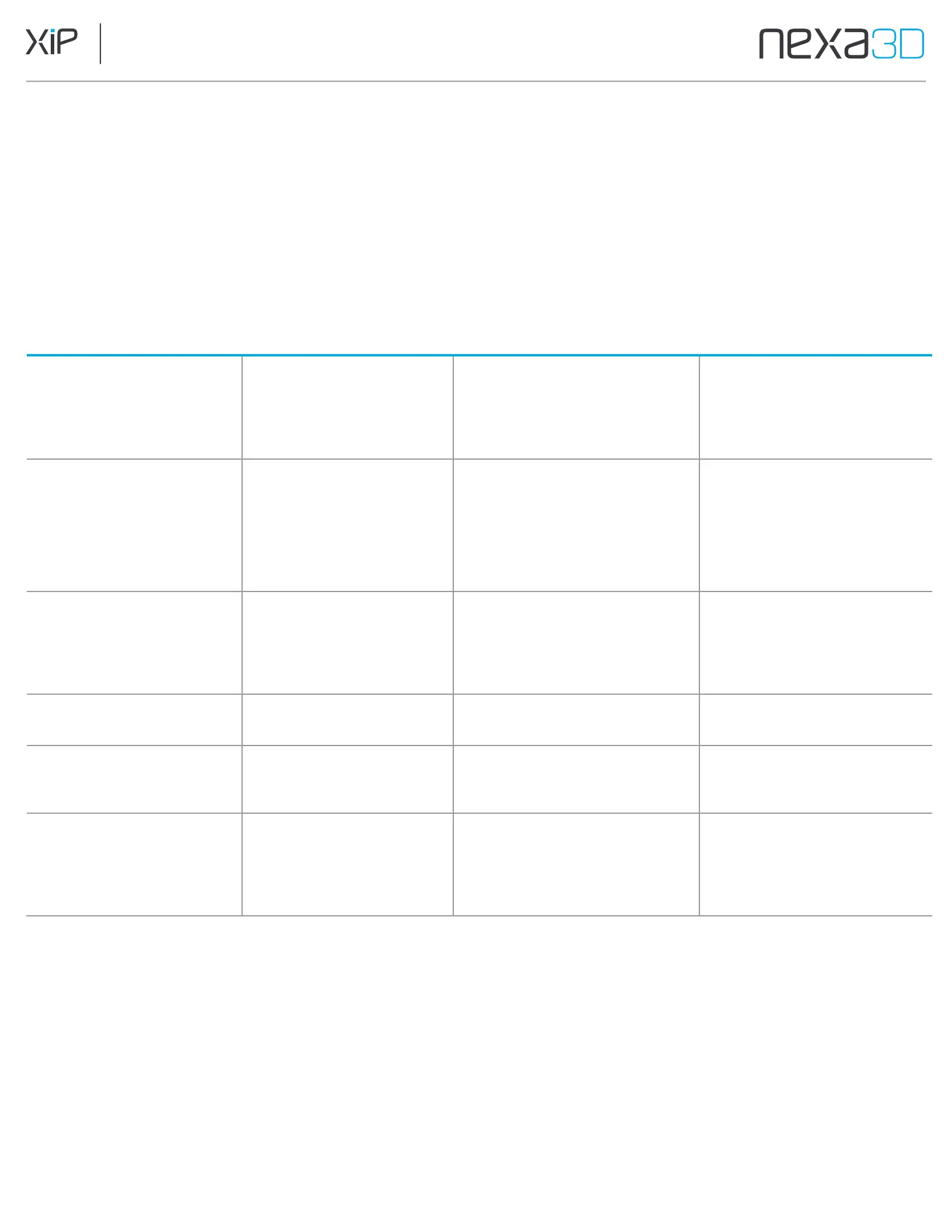

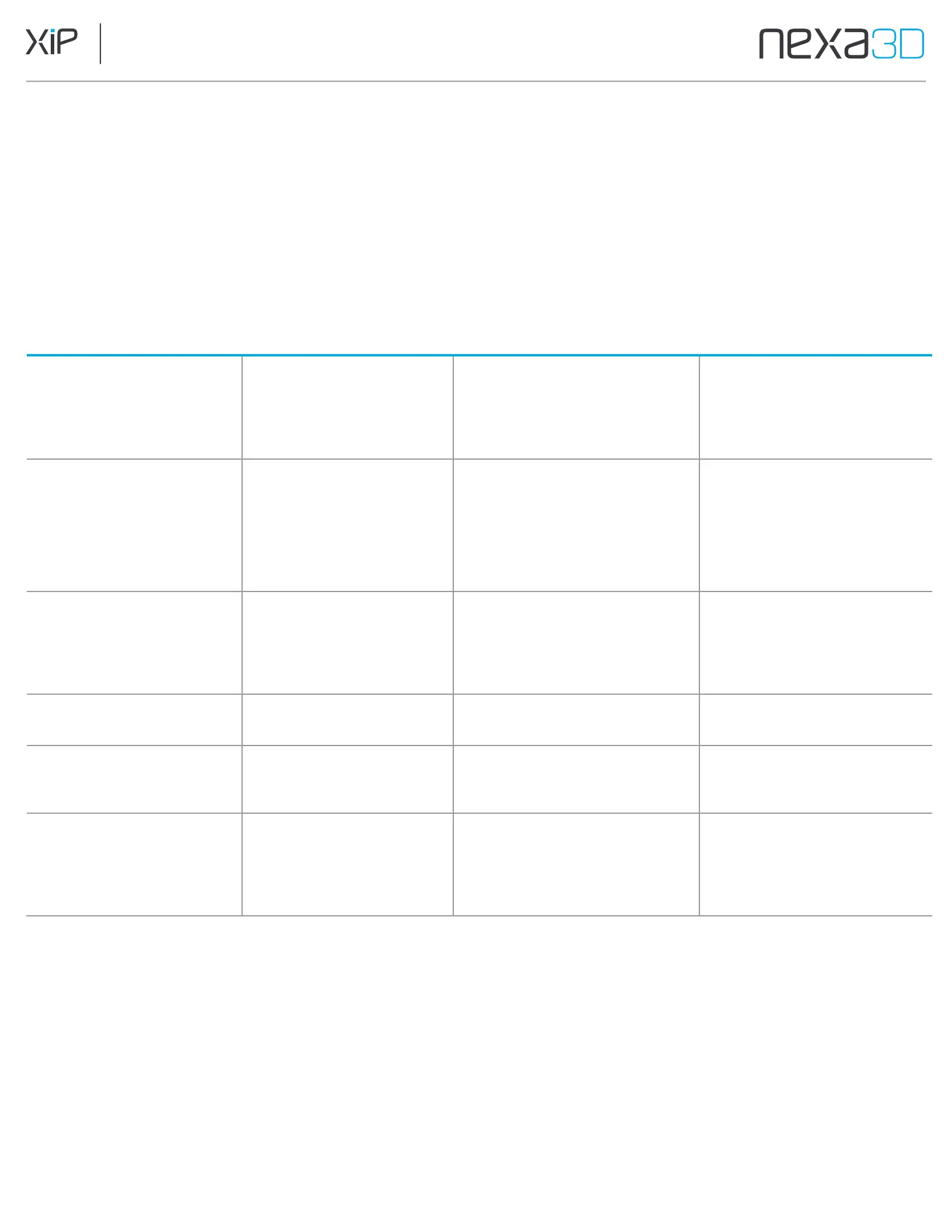

7.1 Inspecting

the

Printer

Adjust the suggested frequency based on personal use.

Inspect Frequency

Look

For

Maintenance

Action

Clean,

flat,

smooth

surface

Use scraper to remove cured resin.

Wash plate in isopropyl

alcohol if needed.

Daily

After any print failure

Membrane has no punctures,

cuts, gouges, or cured resin.

No cured resin particles floating

in the vat

Run the process to clean

the resin vat (Clean Job)

Clean and free of any resin, dust or

other debris

Wipe with IPA to remove liquid

resin and carefully use a razor

blade flush along surface to peel off

thin cured resin layers

Wipe with IPA to remove residue

When LCD is replaced, around

3000 hours of printing

Build plate is level with

the LCD screen

Run the process to level

the build plate

Filter is not dirty or clogged

Replace as needed. We

recommend more frequent

inspections depending on

your environment

Loading...

Loading...