14 – ENGLISH

4.3 ADDRESSING OF DEVICES CONNECTED

WITH THE BLUEBUS SYSTEM

By means of addressing using special jumpers, the “BlueBUS”

system enables the user to make the control unit recognise the

photocells and assign the correct detection function.

The addressing operation must be done on both the TX and RX

photocells (setting the jumpers in the same way), while making

sure there are no other pairs of photocells with the same ad-

dress.

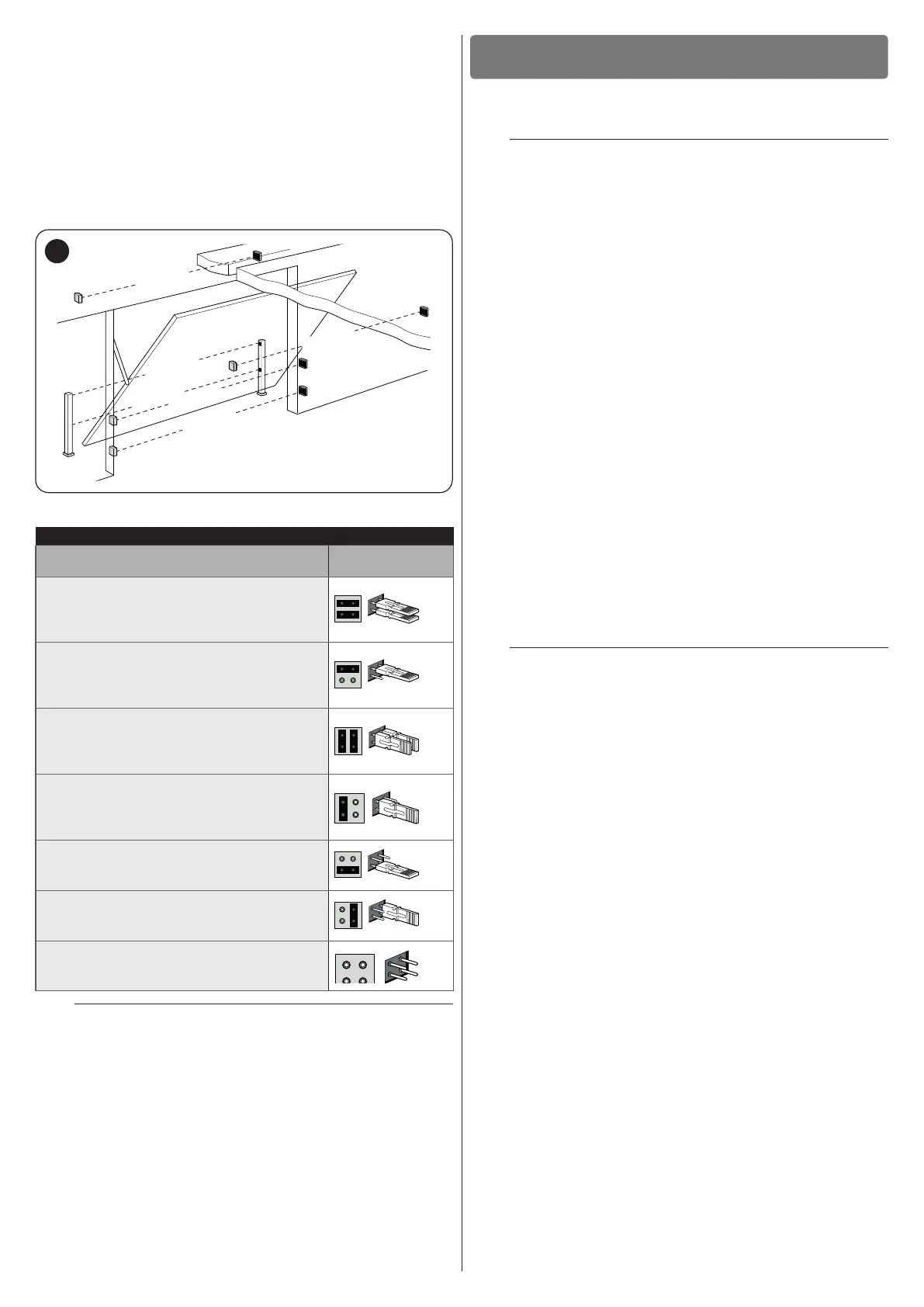

A photocell addressing diagram is shown below, based on the

type of photocell.

FOTO 2

FOTO II

FOTO 2 II

FOTO 1

FOTO II

FOTO

29

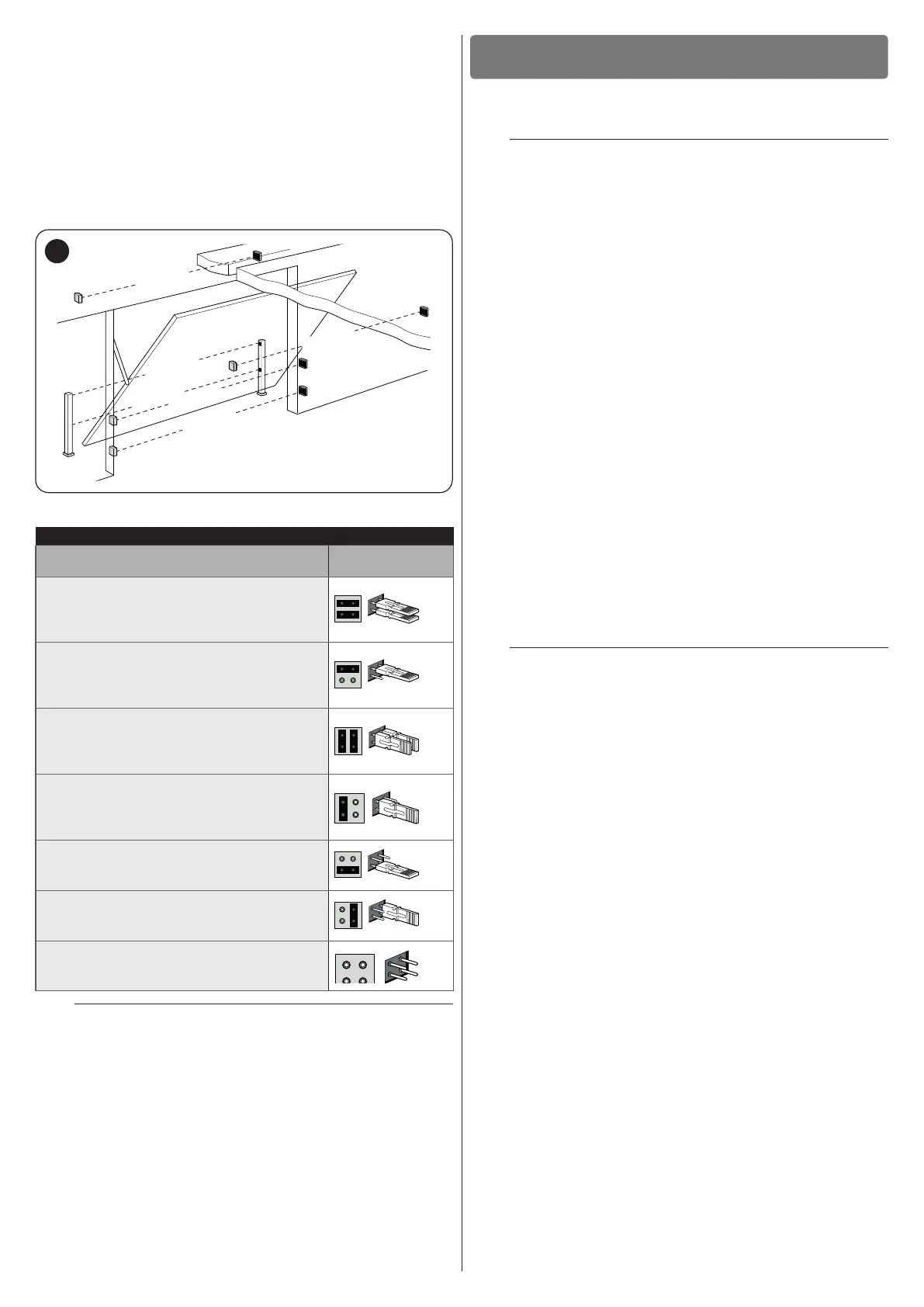

Table 4

PHOTOCELL ADDRESSES

Photocell

Position of the

jumpers

FOTO (PHOTO)

External photocell h = 50 activated during

the closing phase (stops and reverses the

gate’s movement)

FOTO II (PHOTO II)

External photocell h = 100 activated

during the closing phase (stops and

reverses the gate’s movement)

FOTO 1 (PHOTO 1)

Internal photocell h = 50 activated during

the closing phase (stops and reverses the

gate’s movement)

FOTO 1 II (PHOTO 1 II)

Internal photocell h = 100 activated during

the closing phase (stops and reverses the

gate’s movement)

FOTO 2 (PHOTO 2)

External photocell activated during the

opening phase

FOTO 2 II (PHOTO 2 II)

Internal photocell activated during the

opening phase

FOTO 3 (PHOTO 3)

Single photocell covering the entire

automation

m

At the end of the installation procedure, or after

photocells or other devices have been removed,

it is necessary to complete the learning procedure

(see the “Device learning” paragraph).

FINAL CHECKS AND START-UP

5

5 FINAL CHECKS AND START-UP

5.1 POWER SUPPLY CONNECTION

a

The power supply connections must only be made

by qualied and experienced personnel possessing

the necessary requirements and in full conformity

to the laws, regulations and standards in force.

Connect the control unit to a power line equipped with a safety

earthing system. Install a circuit breaker with a contact gap that

ensures full disconnection in the Category III overvoltage condi-

tions, or mount a plug and socket system.

As soon as the product is powered, a few simple checks should

be carried out:

1. check that the display switches on.

2. make sure that the LEDs on the photocells (both the TX

and RX) also ash; the type of ashing is irrelevant, since

it depends on other factors.

3. check that the device connected to the FLASH output or

the LED warning light XBA7 is switched off (with factory

setting).

If the above conditions are not satised, immediately switch

off the power supply to the control unit and carefully check the

electrical connections.

Further useful information on searching and diagnosing faults is

included in the “Troubleshooting” paragraph.

5.2 DEVICE LEARNING

Once the power supply has been connected, the control unit

must recognise the devices connected to the “BlueBUS” and

“STOP” inputs. Prior to this phase, LEDs “L1” and “L2” will ash

to signal that the device learning procedure must be performed.

m

The learning phase must be carried out even if no

device is connected to the control unit.

Loading...

Loading...