16 – ENGLISH

5.5 CONNECTING OTHER DEVICES

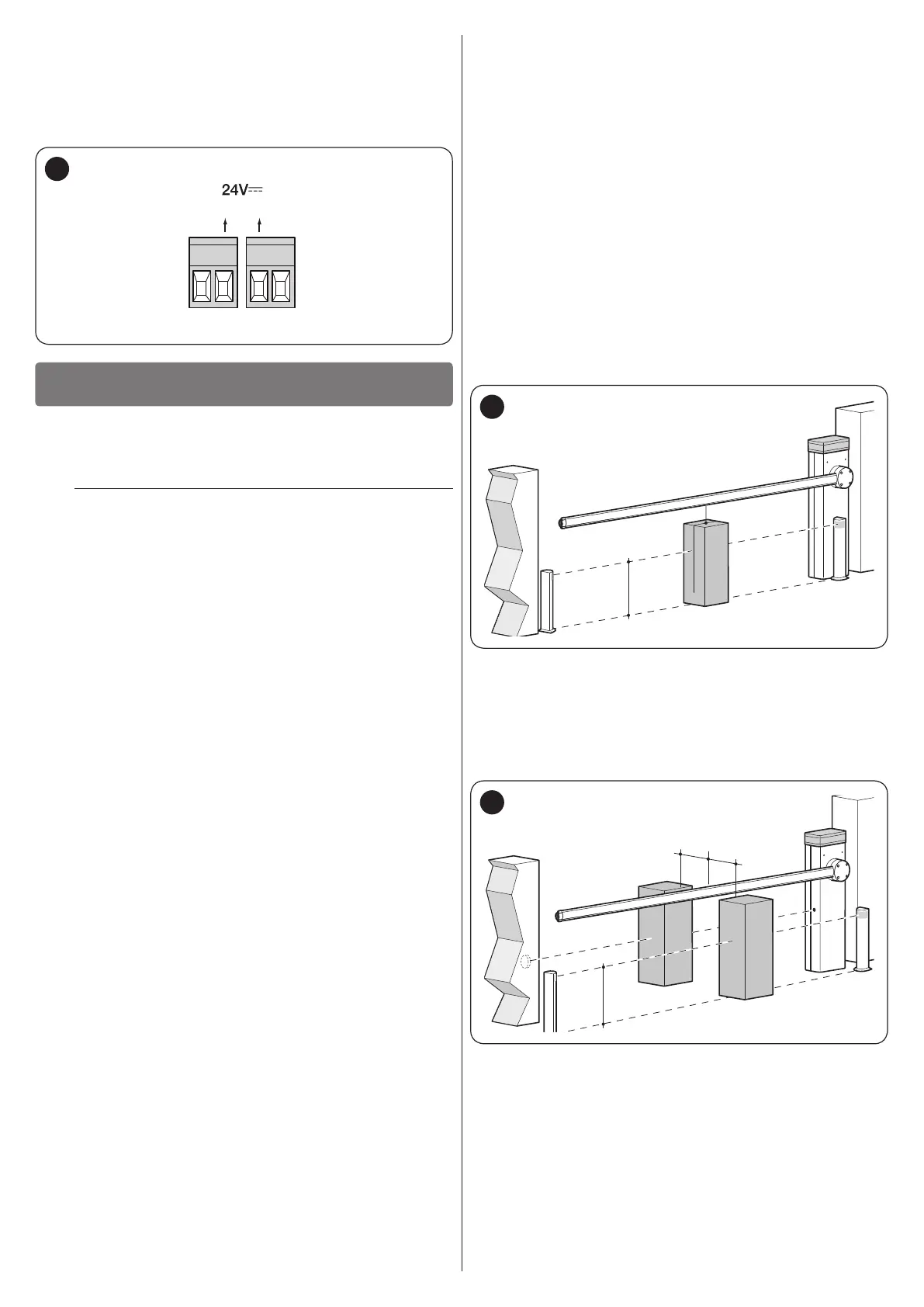

If the user needs to power external devices, such as a radio

receiver or the light of the key selector switch, power can be

tapped as shown in the gure.

The power supply voltage is 24Vc -30% ÷ +50% with a maxi-

mum available current of 100mA.

STOP

SBS

(+)(-)

33

TESTING AND COMMISSIONING

6

6 TESTING AND COMMISSIONING

These are the most important phases of the automation’s con-

struction, as they ensure maximum safety of the system. The

test can also be used to periodically verify the devices making

up the automation.

m

Testing and commissioning of the automation must

be performed by skilled and qualied personnel,

who are responsible for the tests required to ver-

ify the solutions adopted according to the risks

present, and for ensuring that all legal provisions,

standards and regulations are met, in particular all

the requirements of the EN 12445 standard, which

denes the test methods for checking gate automa-

tions.

The additional devices must undergo specic testing, both in

terms of their functions and their proper interaction with the con-

trol unit. Refer to the instruction manuals of the individual devic-

es.

6.1 TESTING

To run the test:

1. verify that all the instructions stated in the “GENERAL

SAFETY WARNINGS AND PRECAUTIONS” chapter

have been strictly observed

2. check that the boom is correctly balanced (see paragraph

“Boom balancing“)

3. check that the manual unlocking device works properly

(see paragraph “Manually unlocking and locking the

gearmotor“)

4. using the control devices (transmitter, control push-but-

ton, key selector, etc.), test the boom opening, closing

and stopping phases, ensuring that the movement match-

es the specications. Several tests should be conducted

to assess the boom’s movement and to check for any as-

sembly or adjustment defects or any particular points of

friction

5. check, one-by-one, that all safety devices mounted on the

system (photocells, sensitive edges, etc.) work properly.

Each time a device intervenes, the “Bluebus” LED on the

control unit will emit two faster ashes to conrm the rec-

ognition

6. verify the correct operation of the photocells in the follow-

ing way:

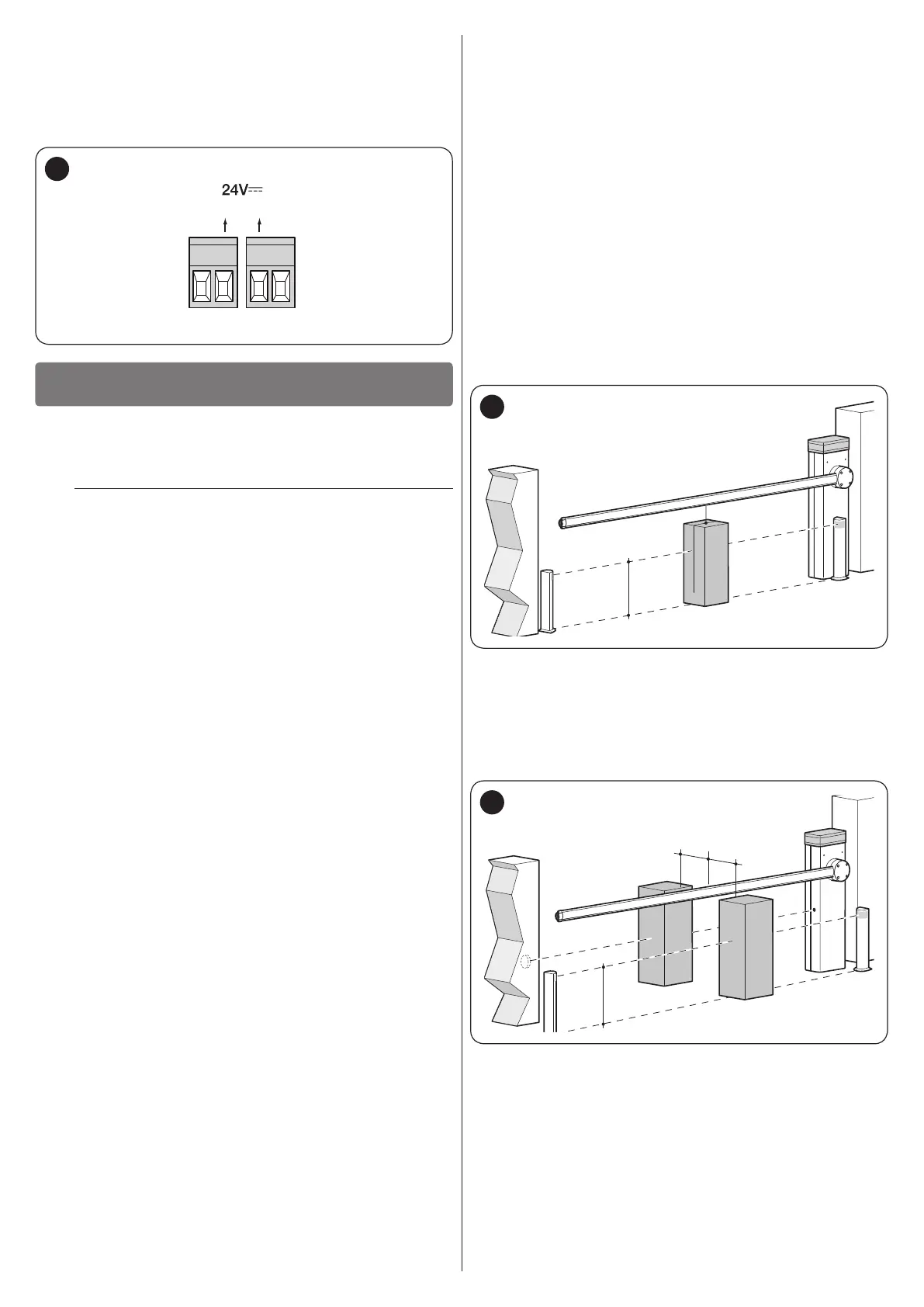

– depending on whether one or two pairs of photocells

have been installed, one or two blocks of rigid ma-

terial (e.g. wooden panels) are required, measuring

70x30x20 cm. Each block must have three sides of re-

ective material (e.g. mirror or glossy white paint), one

for each dimension, and three sides of opaque material

(e.g. matt black paint). To test the photocells positioned

50 cm above the ground, the block must be placed on

the ground, or raised to 50 cm when testing photocells

positioned 1 m above the ground

– if the test is on a pair of photocells, the testing block

must be placed directly under the centre of the boom

with the 20 cm sides facing the photocells and moved

along the entire length of the boom

300

200

700

500

34

– if the test is on two pairs of photocells, the test must

rst be performed individually for each pair of photo-

cells using one testing block and then repeated using

two testing blocks; each testing block must be posi-

tioned laterally in relation to the centre of the boom, at

a distance of 15 cm and then moved along the entire

length of the boom

300

200

700

300

200

700

500

150

150

35

Loading...

Loading...