ENGLISH – 17

– during these tests, the testing block must be detected

by the photocells in any position it lies along the entire

length of the boom

7. check that there are no interferences between the photo-

cells and other devices:

– block the line of sight between the pair of photocells

with a cylinder (diameter 5 cm, length 30 cm), by mov-

ing it close to the TX photocell rst then next to the RX

photocell and then at the mid-point between the two

36

– check that the device intervenes in all cases, switching

from the active to the alarm status and vice-versa

– check that it triggers the intended action in the control

unit (e.g. a reversal of the movement during the closing

manoeuvre)

8. check on the safeguard against the lifting hazard: in

automations with vertical movement it is necessary to ver-

ify that there is no lifting hazard. This test can be carried

out in the following way:

– hang a 20 kg load (e.g. a sand bag) midway along the

boom’s length

– send an opening command and check that during the

manoeuvre the boom does not exceed a height of 50

cm above its closed position

– if the boom exceeds this height, the motor force must

be reduced (refer to the chapter “PROGRAMMING“)

9. if potentially dangerous situations due to the boom’s

movement have been prevented by limiting the impact

force, the latter must be measured according to the EN

12445 standard and, if the “motor force” control is used

to aid the system in reducing the impact force, it is neces-

sary to test various adjustments to nd the one that gives

the best results

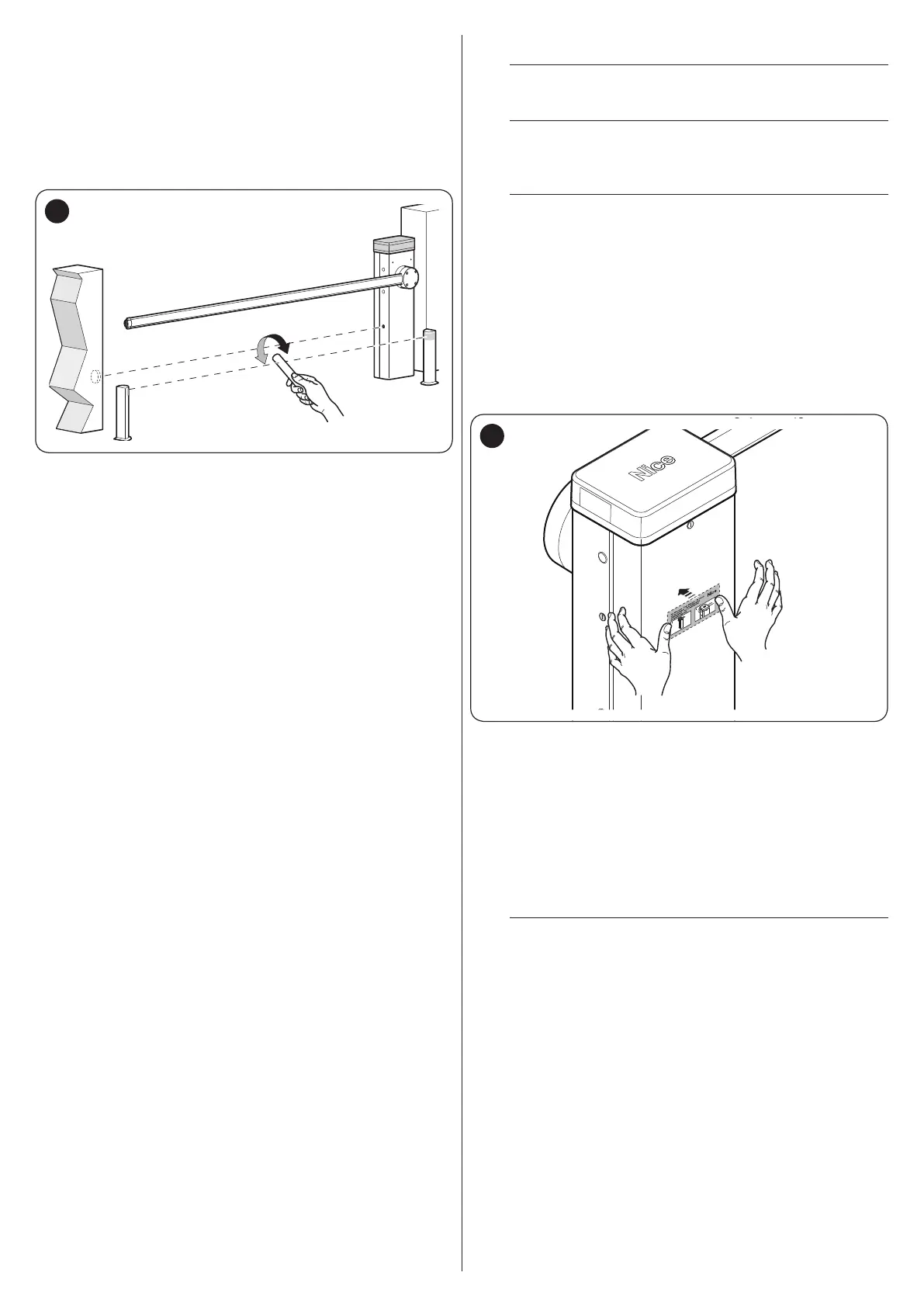

10. checking the efciency of the unlocking system:

– put the boom in the closed position and manually un-

lock it (see paragraph “Manually unlocking and lock-

ing the gearmotor“)

– verify that this occurs smoothly

– verify that the manual force to move the boom during

the opening phase does not exceed 200 N (roughly 20

kg)

– the force is measured perpendicularly to the boom at 1

m from the rotation axis

11. verication of the power supply disconnection sys-

tem: operate the power disconnection device and dis-

connect any available back-up batteries; check that all

the LEDs on the control unit are OFF and that the boom

remains stationary when a command is sent. Check the

efciency of the locking system to prevent any uninten-

tional or unauthorised connection.

6.2 COMMISSIONING

a

Commissioning can only be performed after all test-

ing phases have been successfully completed.

a

Before commissioning the automation, ensure that

the owner is properly informed of all residual risks

and hazards.

a

The gate cannot be commissioned partially or un-

der “temporary” conditions.

To commission the automation:

1. compile the automation’s technical le, which must in-

clude the following documents: overall drawing of the

automation, wiring diagram, risk assessment and relative

solutions adopted, the manufacturer’s declaration of con-

formity for all devices used and the declaration of con-

formity compiled by the installer

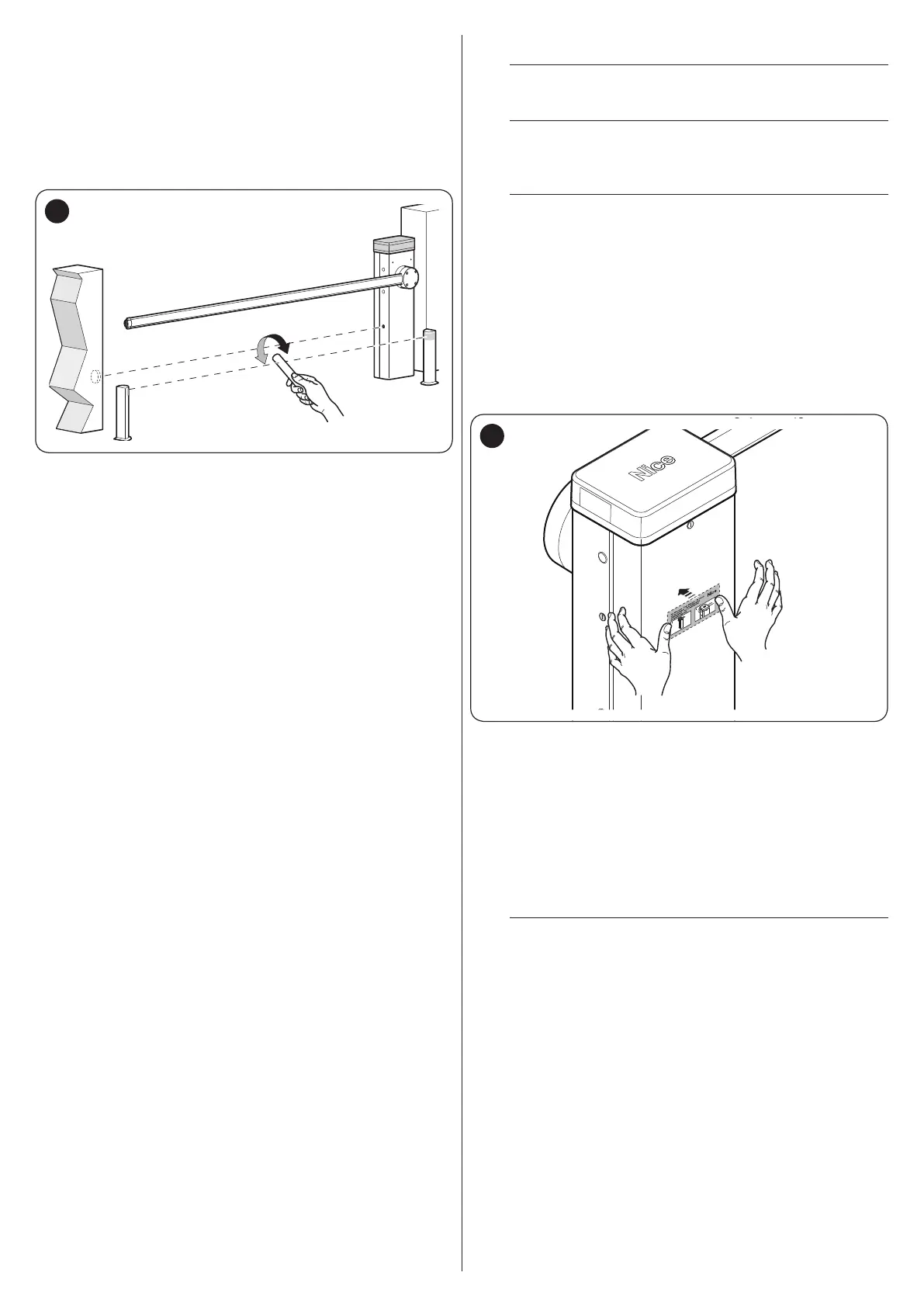

2. afx a permanent label or sign on the cubicle specifying

the operations for unlocking the gate and manoeuvring it

manually “Figure 37“

37

3. afx a data plate to the cubicle specifying at least the

following data: type of automation, name and address of

the manufacturer (responsible for commissioning), serial

number, year of manufacture and CE mark

4. compile the declaration of conformity of the automation

and hand it to the owner of the automation

5. compile the User Manual of the automation and hand it to

the owner of the automation

6. compile and provide the owner with the automation’s

“Maintenance schedule”, containing the maintenance in-

structions for all the automation’s devices.

l

For all the above-mentioned documentation, Nice –

through its technical assistance service – provides

the following: pre-completed forms.

Loading...

Loading...