Safety information Introduction Product information System configuration

Mechanical

Installation

Electrical Installation

Unidrive M Modular Installation Guide 47

Issue Number: 2

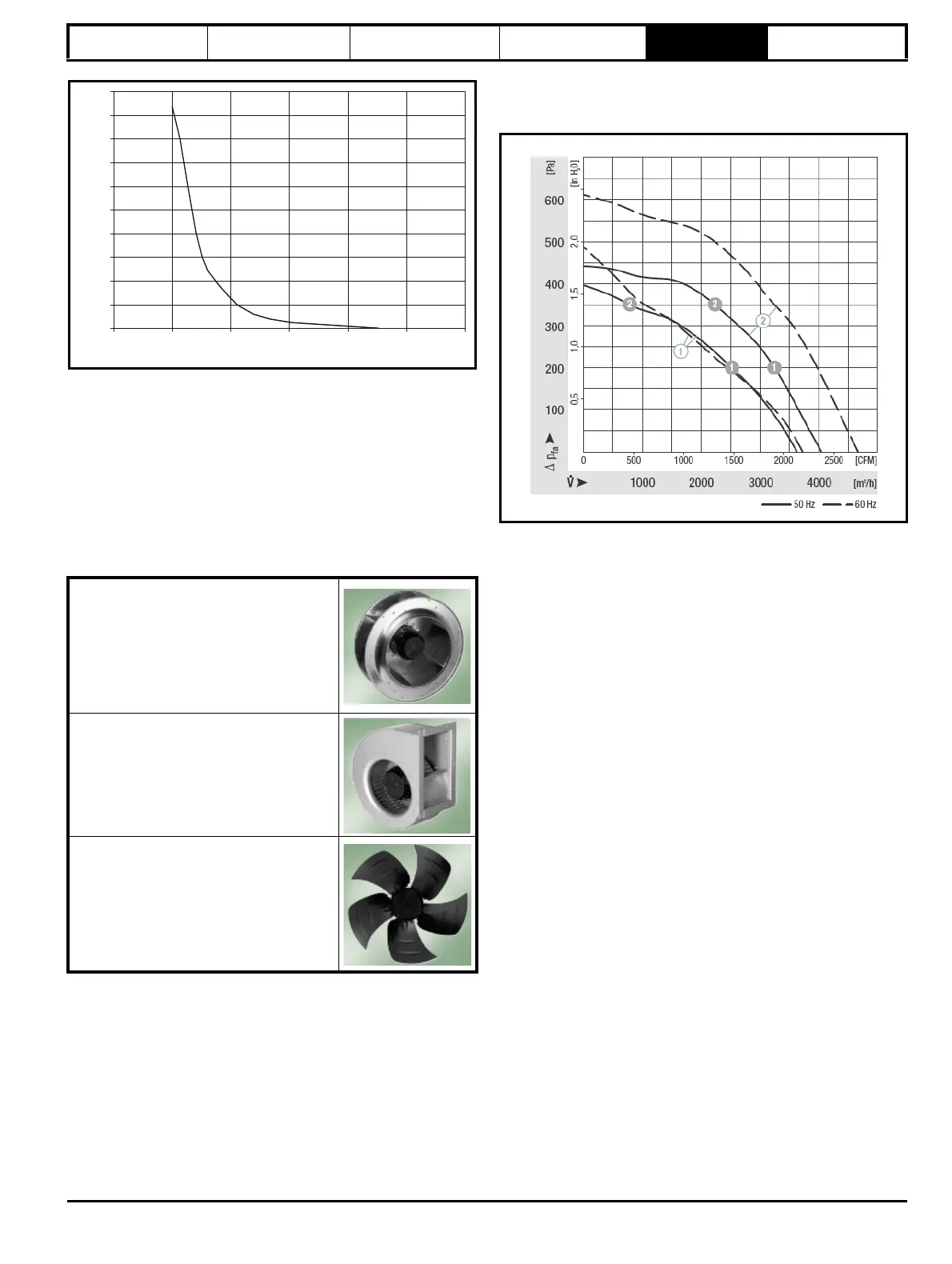

Figure 5-30 Pressure drop

Best practice: Size the enclosure air inlet and exit vents at least as

large as the venturi opening of the fan used. This will ensure a negligible

back pressure.

With 52.5 % open area: Pressure drop = 34

Selecting fan

Considerations when selecting fan:

• Dimensions and space limitation

• Required flow rate

• Static pressure

•Noise level

• Power supply

Table 5-5 Type of fan

Fan curves

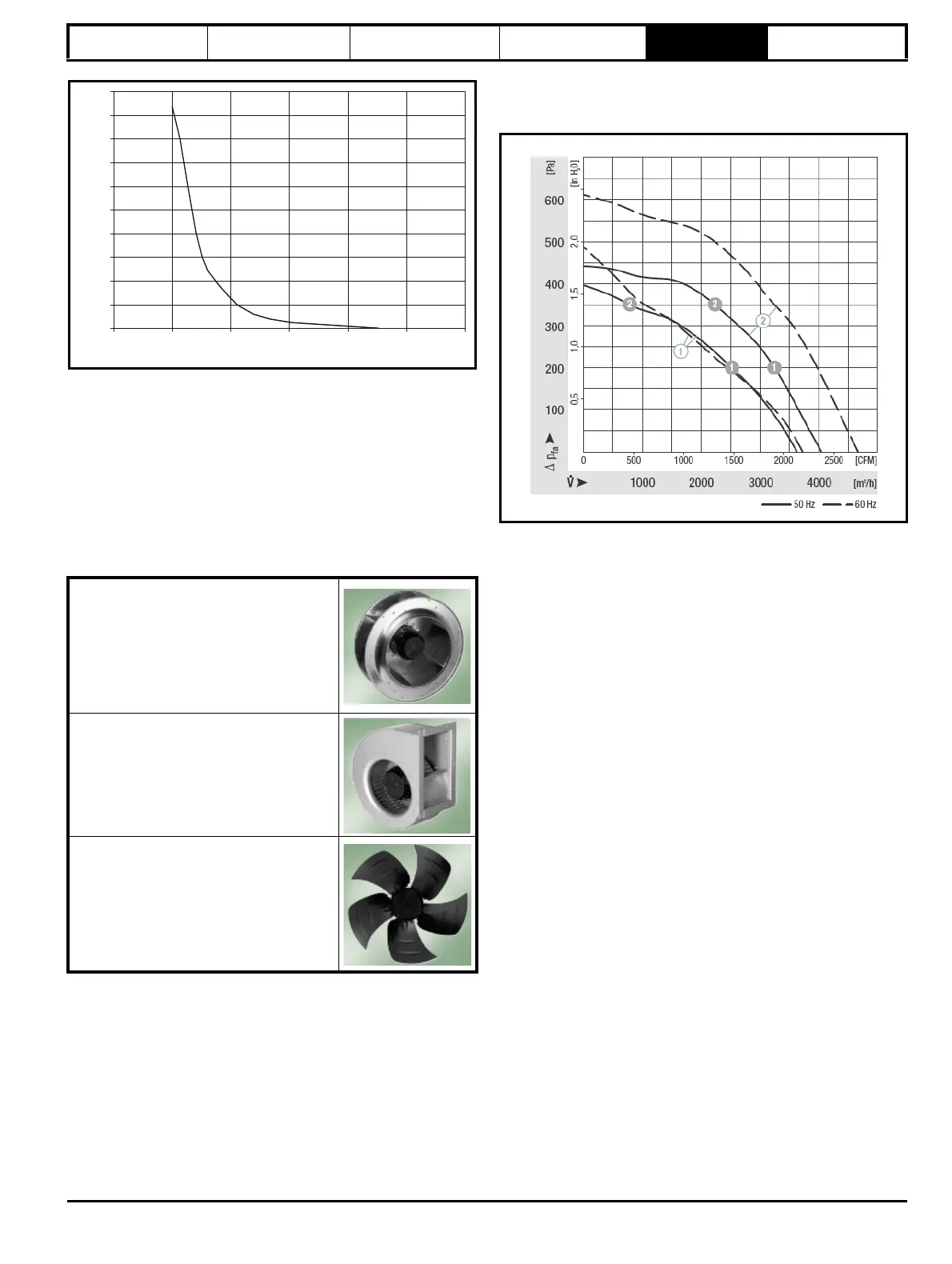

Once the type of fan has been selected the next step is to match the

system characteristics of your enclosure to the fan performance curve.

System operating point is:

Static pressure = 34 Pa

Flow rate= 4212.5 m

3

/hr

Selected fan is a Backward curved centrifugal blower to place in the roof

and take advantage of the perpendicular flow and high flow rate

properties.

Figure 5-31 AC supply 400 mm diameter blower performance

Final summary

1. Enclosure fans can be placed on inlet and outlet depending on

system limitations.

2. Considerations with fan on outlet:

• Higher Ambient temperature surrounding fan, can affect fan life.

• Depressurisation of enclosure which may draw in dust through

any apertures.

3. Considerations with fan on inlet:

• Proximity of dust filter to fan, can create excess back pressure

on fan

• Non-uniform flow across internal components

4. Dust filters:

Use the largest filter possible, in order to:

a. Increase dust capacity

b. Reduce pressure drop

5. Make sure Drive inlets are as close to the enclosure air inlet as

possible

6. Do not block the inlet and outlets of the drive airflow. Keep to best

practice spacing between drives and other parts in enclosure.

7. Beware of blocking air inlets or outlets with cable routing.

5.7 Heatsink fan operation

The Unidrive M size 9, 10 and Rectifier are ventilated by a heatsink

mounted fan and an auxiliary fan to ventilate the drive box. The fan

housing forms a baffle plate, channelling the air through the heatsink

chamber. Thus, regardless of mounting method (surface mounting or

through-panel mounting), the installation of additional baffle plates is not

required.

Ensure the minimum clearances around the drive are maintained to

allow air to flow freely.

The heatsink fan on Unidrive M size 9, 10 and Rectifier is a variable

speed device. The drive controls the speed at which the fan runs based

on the temperature of the heatsink and the drive's thermal model

system. The Unidrive M size 9 and 10 are also installed with variable

speed fans to ventilate the capacitor bank.

Backward curved Blower (Centrifugal)

• Outward flow perpendicular to inward flow

• Good at high + low back pressures

• Good resistance to dust and dirt due to

impeller design

• Do not need cowling

• Relatively small diameters required for

high airflow

Forward curved blower (Centrifugal)

• Requires cowling

• Good at directing flow

Axial Fan

• Not good at high pressure but good for

low pressure applications such as room

venting and ducting

• Inward flow and outward flow is in same

direction

• Good in straight line duct applications.

• Large diameters required for high air flows

250

200

150

100

50

0

Pressure drop (Pa)

0 20406080

Total open area (%)

100

400

350

300

500

450

80

Loading...

Loading...