Safety information Introduction Product information System configuration

Mechanical

Installation

Electrical Installation

68 Unidrive M Modular Installation Guide

Issue Number: 2

6.10 EMC (Electromagnetic compatibility)

The requirements for EMC are divided into three levels in the following

three sections:

Section 6.10.2, General requirements for all applications, to ensure

reliable operation of the drive and minimise the risk of disturbing nearby

equipment. The immunity standards specified in section 11 will be met,

but no specific emission standards. Note also the special requirements

given in Surge immunity of control circuits - long cables and connections

outside a building on page 74 for increased surge immunity of control

circuits where control wiring is extended.

Section 6.10.3, Requirements for meeting the EMC standard for

power drive systems, IEC61800-3 (EN61800-3:2004).

Section 6.10.4, Requirements for meeting the generic emission

standards for the industrial environment, IEC61000-6-4, EN61000-6-

4:2007.

The recommendations of section 6.10.2 General requirements for

EMC on page 69 will usually be sufficient to avoid causing disturbance

to adjacent equipment of industrial quality. If particularly sensitive

equipment is to be used nearby, or in a non-industrial environment, then

the recommendations of section 6.10.3 Compliance with EN 61800-

3:2004 (standard for Power Drive Systems) on page 71 or section

6.10.4 Compliance with generic emission standards on page 72 should

be followed to give reduced radio-frequency emission.

In order to ensure the installation meets the various emission standards

described in:

• The EMC data sheet available from the supplier of the drive

• The Declaration of Conformity at the front of this manual

The correct external EMC filter must be used, and all of the guidelines in

section 6.10.2 General requirements for EMC on page 69 and section

6.10.4 Compliance with generic emission standards on page 72 must be

followed.

N

The installer of the drive is responsible for ensuring compliance with the

EMC regulations that apply where the drive is to be used.

6.10.1 Internal EMC filter

It is recommended that the internal EMC filter be kept in place unless

there is a specific reason for removing it.

If the drive is used as part of a regen system, then the internal EMC filter

must be removed.

The internal EMC filter reduces radio-frequency emission into the line

power supply. Where the motor cable is short, it permits the

requirements of EN61800-3:2004 to be met for the second environment

- see section 6.10.3 Compliance with EN 61800-3:2004 (standard for

Power Drive Systems) on page 71. For longer motor cables the filter

continues to provide a useful reduction in emission level, and when used

with any length of shielded motor cable up to the limit for the drive, it is

unlikely that nearby industrial equipment will be disturbed. It is

recommended that the filter be used in all applications unless the ground

leakage current of 56 mA is unacceptable or the above conditions are

true. See Figure 6-13 on page 68 for details of removing and installing

the internal EMC filter.

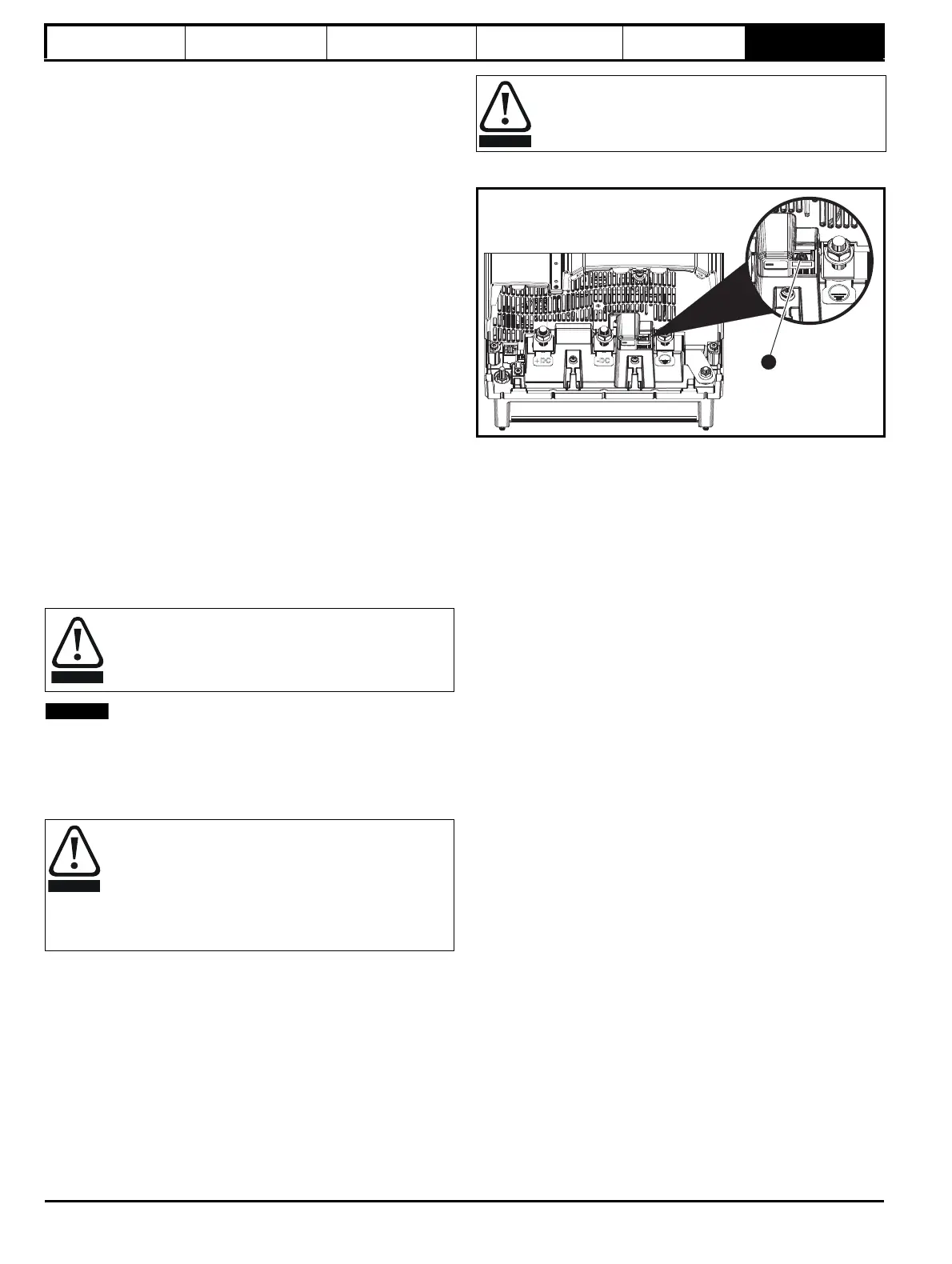

Figure 6-13 Removal of the Unidrive M size 9 and 10 Inverter

internal EMC filter

To electrically disconnect the Internal EMC filter, remove the screw as

highlighted above (1).

High ground leakage current

When an EMC filter is used, a permanent fixed ground

connection must be provided which does not pass through a

connector or flexible power cord. This includes the internal

EMC filter.

When the drive is used with ungrounded (IT) supplies the

internal EMC filter must be removed unless additional motor

ground fault protection is installed.

For instructions on removal, refer to Figure 6-13 Removal of

the Unidrive M size 9 and 10 Inverter internal EMC filter on

page 68.

For details of ground fault protection contact the supplier of

the drive.

The supply must be disconnected before removing the

internal EMC filter.

Loading...

Loading...