Safety information Product information Mechanical installation Electrical installation Multi axis system design Technical data

Digitax HD M75X Series Installation and Technical Guide 87

Issue Number: 5

5.1.3 DC paralleling fed from a separate DC source such as a rectifier stack or larger drive from the Digitax

HD range

There are a number of advantages in using this method of DC paralleling:

• Allows drives of different frame sizes to be connected together.

• Reduces AC supply side component parts.

• Reduces energy losses (heat loss from braking resistors).

There are limitations to the combinations of drives which can be used in this configuration. For further information, contact the supplier of the drive.

5.2 DC bus paralleling connection method

DC bus paralleling using standard cable/busbars is supported by all frame sizes in the Digitax HD M75X range.

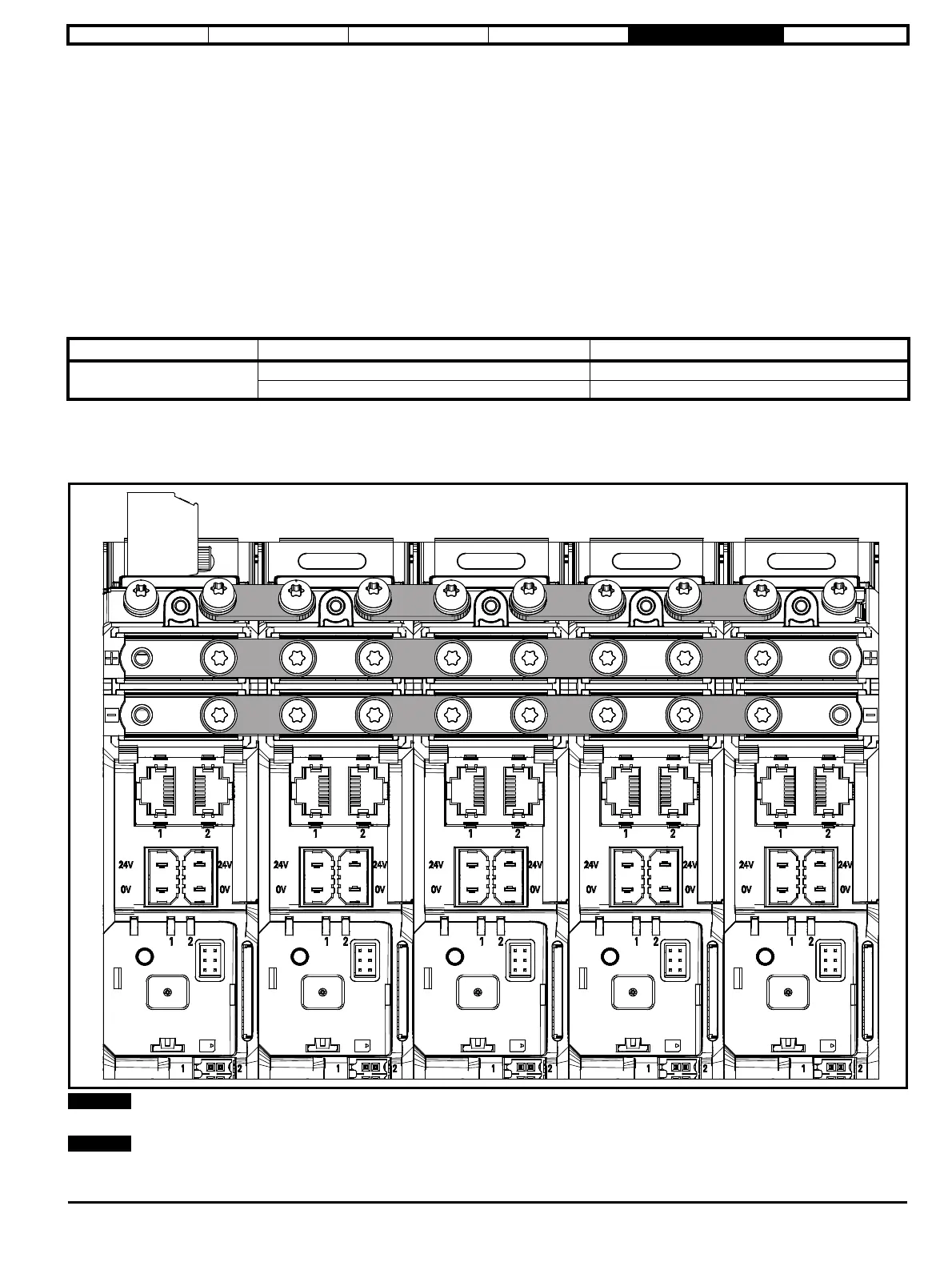

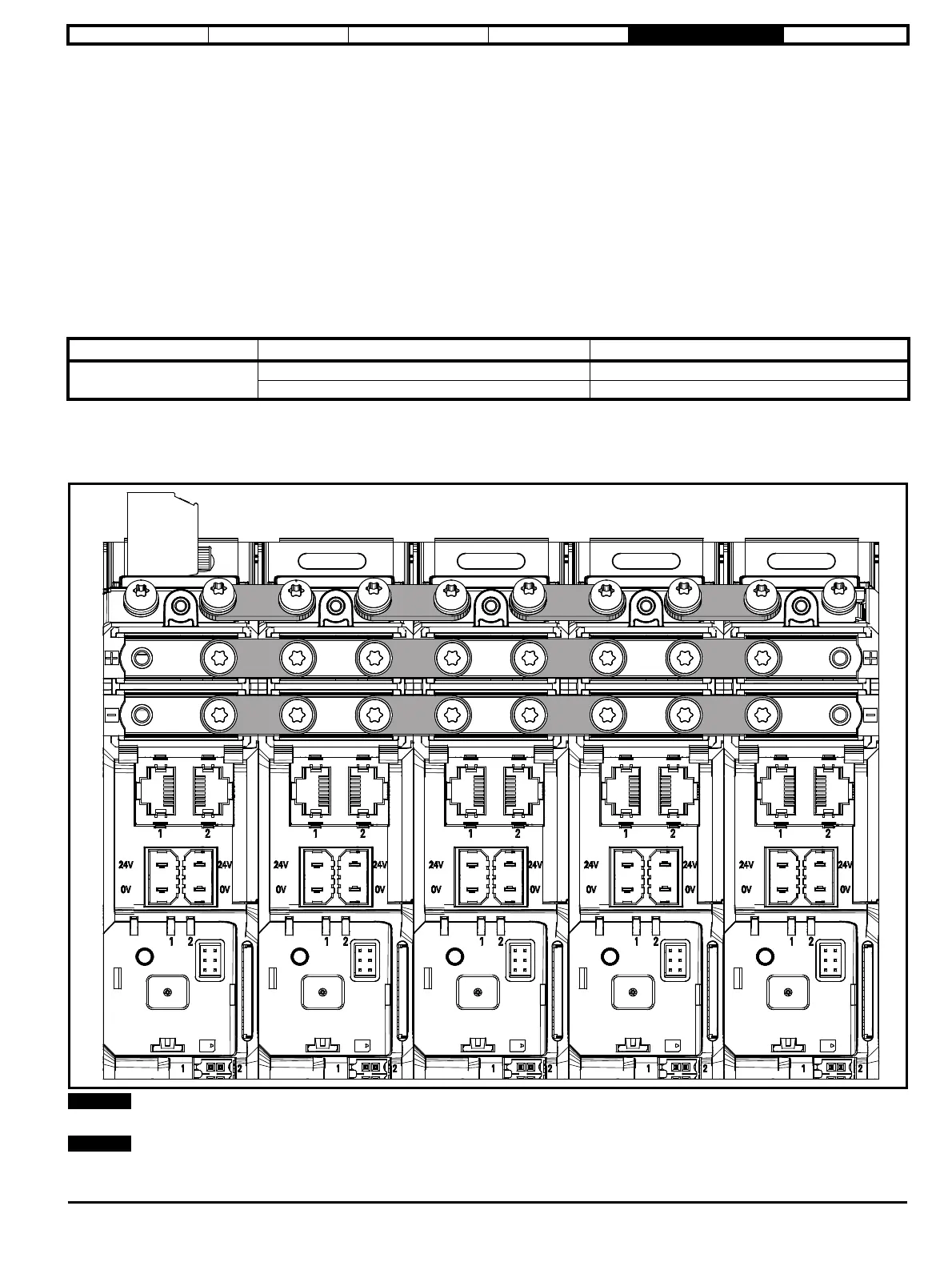

5.2.1 DC paralleling with busbars

The terminal and enclosure design enables the DC bus of a number of drives to be connected together using pre-made busbars. Suitable busbar

links for DC paralleling are included in multi axis kits available from the supplier of the drive; refer to Table 5.3 External 24 Vdc supply requirements for

multi axis systems.

Table 5-5 Multi axis kit part numbers

Multi axis kits are not supplied with the drive but available to order from the supplier of the drive.

The diagram below shows how the DC and ground busbar links should be used to connect several drives together. For access to the drive DC bus

terminal refer to section 4.3.1 DC terminal cover access/removal on page 51.

Figure 5-2 Parallel DC bus and ground connections using busbar links (DC bus cover removed for clarity)

The DC busbar system is rated at 60 A continuous.

DC terminal cover breakout tabs must not be removed when connecting multi axis drives using pre-made busbars supplied in the multi axis kits.

Model Description Part number

All

Multi axis kit (standard - no option module) 9500-1047

Multi axis kit (with option module) 9500-1048

Loading...

Loading...