General Information

25

Service Manual – SW4000

Maintenance

The lifespan of the machine and its maximum operating safety are ensured by correct and regular mainte-

nance.

Warning! Read carefully the instructions in the Safety chapter before performing any

maintenance procedure.

The following tables provides the scheduled maintenance. The intervals shown may vary according to particu-

lar working conditions, which are to be dened by the person in charge of the maintenance.

For instructions on maintenance procedures, see the following paragraphs.

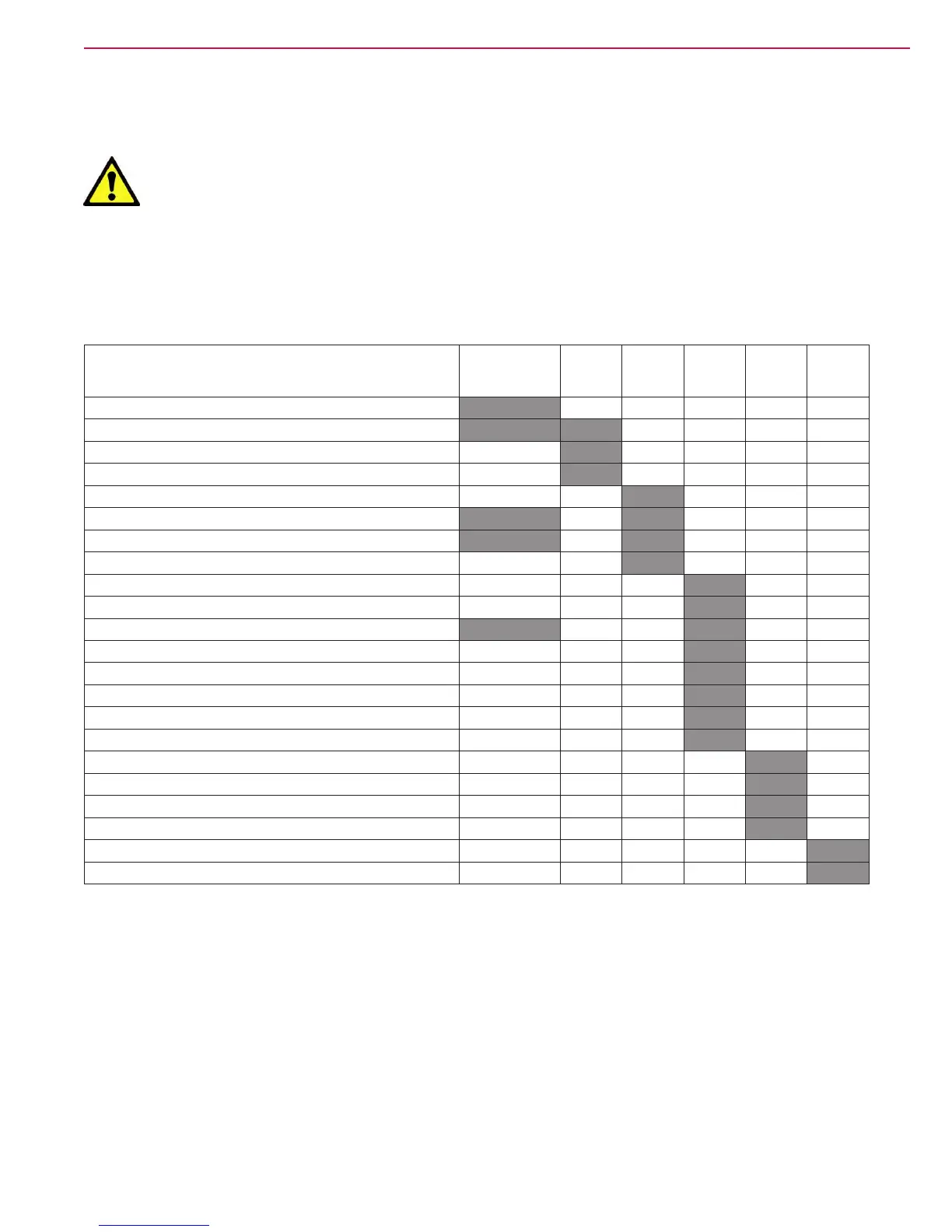

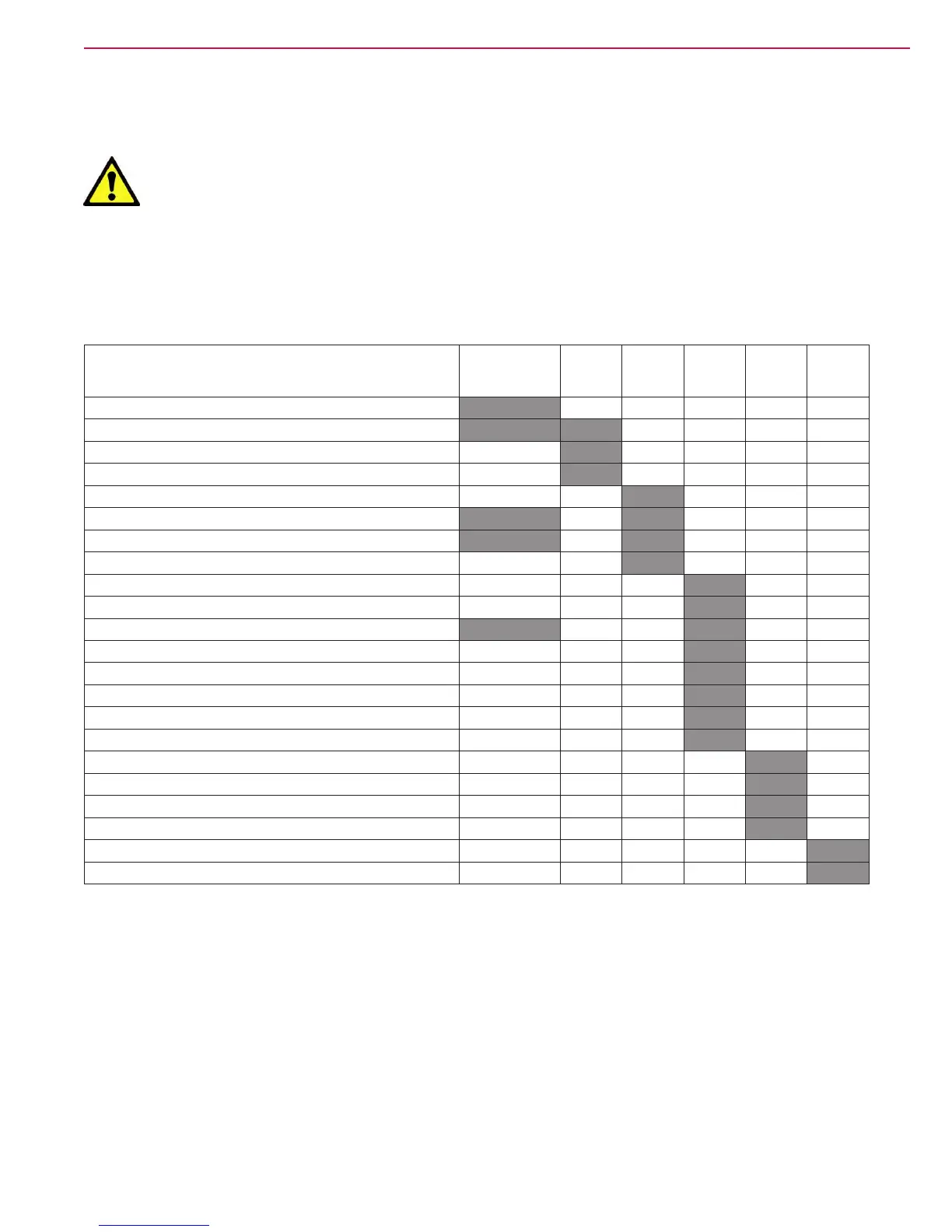

Scheduled Maintenance Table (SW4000 Battery)

Procedure

Upon

delivery

Every

10

hours

Every

50

hours

Every

100

hours

Every

200

hours

Every

year

Battery charging (1)

Battery (WET) uid level check (2)

Side and main broom height check

Service brake cable adjustment (3)

Hopper dust lter check and cleaning (“A” method) (4)

Hopper hydraulic lifting system oil level check (2)

Skirt height and operation check

Dust guard system water lter check and cleaning

Hopper dust lter check and cleaning (“B” method) (4)

Filter shaker operation check

Main broom driving belt check

Brake adjustment

Nut and screw tightening check (5)

Steering chain cleaning

Safety system operation check (2)

Brake pad check/adjustment/replacement (3)

Hopper dust lter check and cleaning (“C” method) (4)

Main broom driving belt replacement

Hopper gasket integrity check

Lifted hopper sensor operation check/adjustment

Motor carbon brush check and replacement

Hydraulic system oil change (6)

(1) Daily or after using the machine.

(2) Or before start-up.

(3) Or more frequently if the machine is used on slopes.

(4) Or more often in dusty areas.

(5) And after the rst 8 running-in hours.

(6) Change the hydraulic system oil for the rst time after 500 hours, then every 2,000 hours or every year.

Loading...

Loading...