Engine System - Petrol 90Service Manual – SW4000

Engine System - Petrol

Functional Description

The engine system generates electric current for all

machine functions.

The assembly consists of an internal combustion en-

gine and dynamotor, which are both connected to the

main crankshaft.

The engine is a single-cylinder air-cooled petrol type.

The engine start-up is made by the dynamotor to

which it is connected.

The dynamotor acts as a starter, using the battery

only for the time necessary to start the engine.

At a later stage, the running engine supplies the

power to the dynamotor to generate the current and

to power the electrical systems of the machine. The

surplus current is used to charge the batteries.

The engine speed is xed, 2,750 rpm, to grant a con-

stant current to the electrical system.

The fuel tank is fastened outside the engine, in the

rear side of the machine. The tank has a fuel level in-

dicator with oat, and a valve with integrated lter.

The choke lever on the engine has been extended in

order to be easily activated from the driver’s seat po-

sition.

The fuel reserve warning light turns on when the fuel

in the tank is less than 2.2 liters.

The engine is equipped with an oil level sensor (Oil

Alert), which purpose is to avoid damages caused by

an insufcient oil quantity in the oil pan. Before the

oil level goes below the safety limit, the system (Oil

Alert) automatically stops the engine shorting the

spark plug to the chassis..

If the engine stops and do not restart, check the en-

gine oil level before doing any other troubleshooting

procedure.

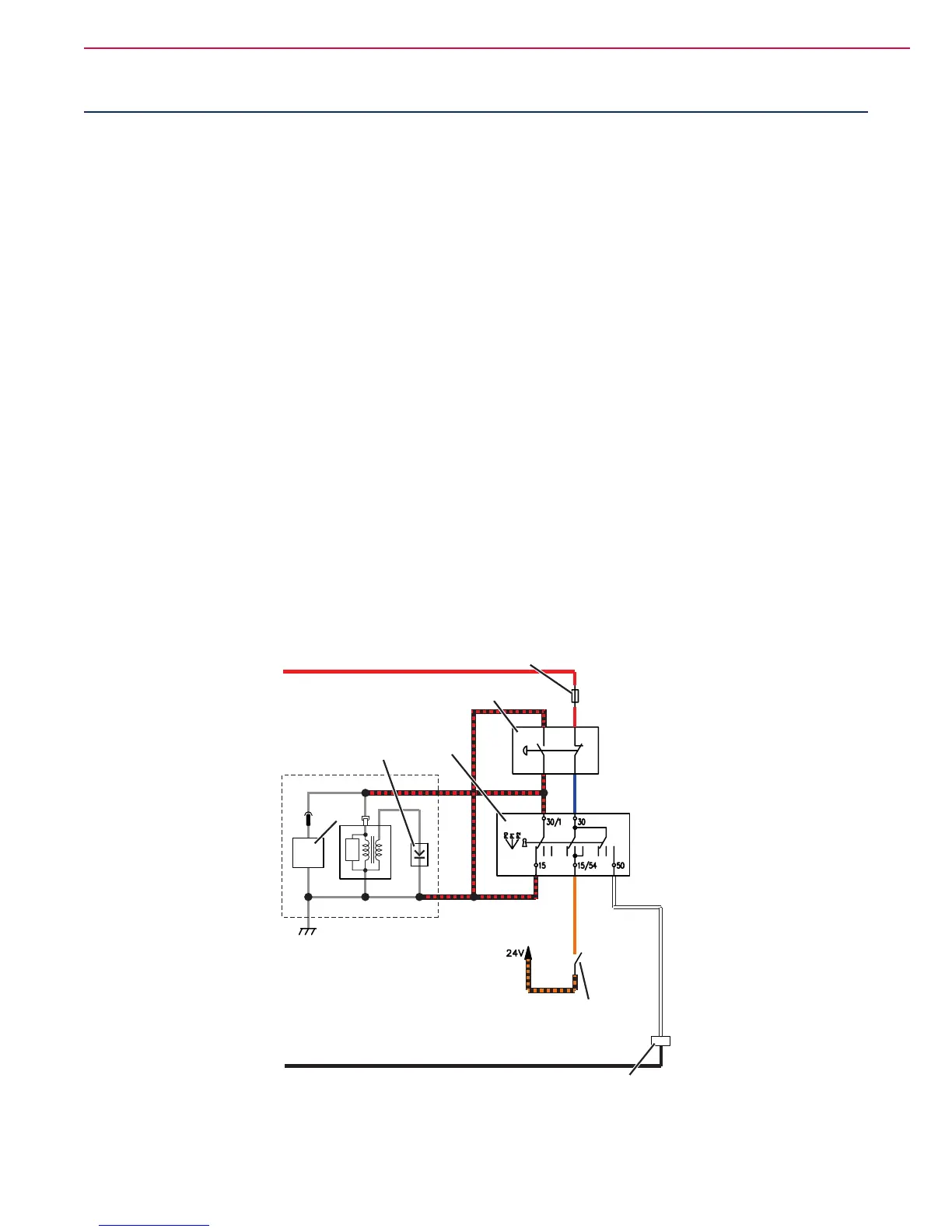

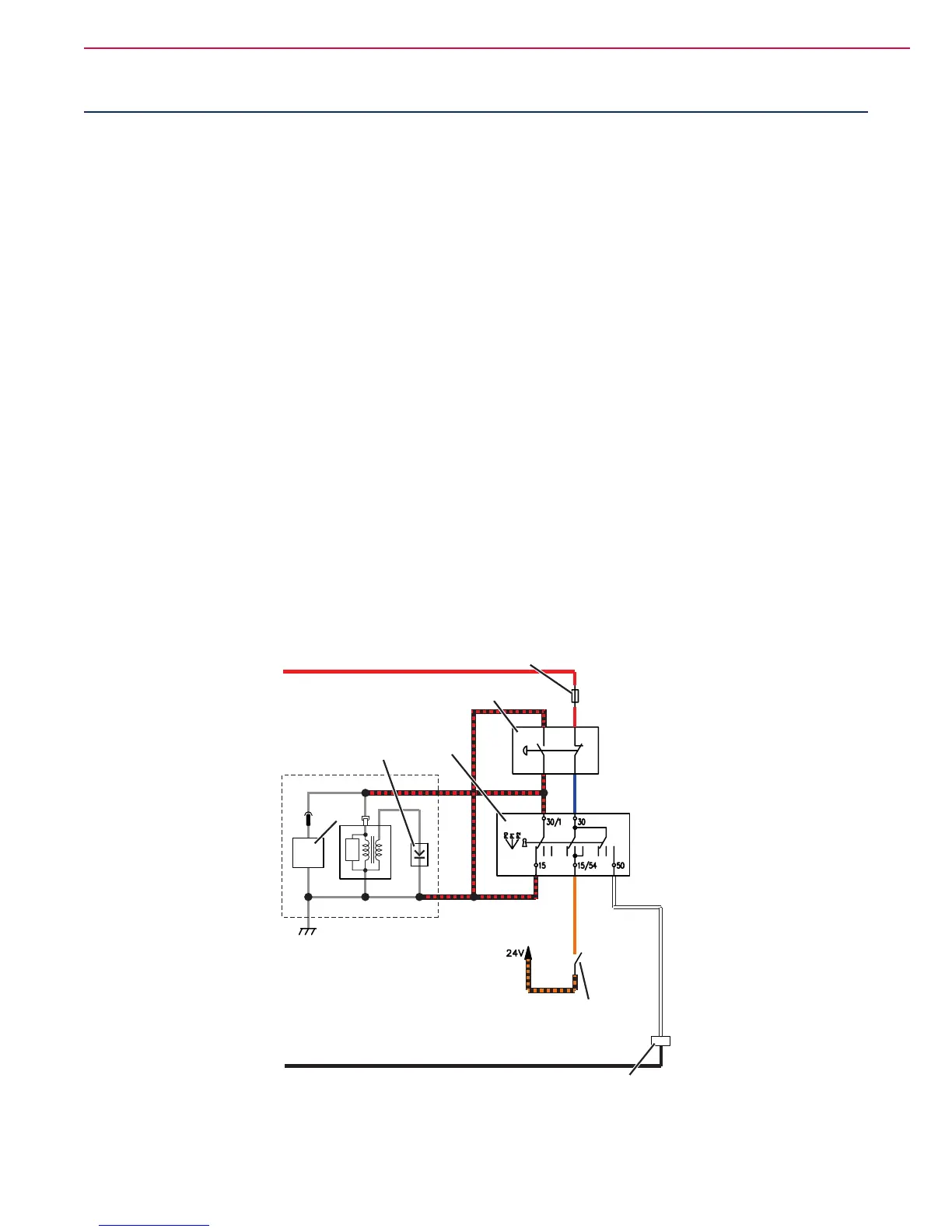

Wiring Diagram

FUSE (F4)

IGNITION

KEY (SW1)

EMERGENCY

PUSH-BUTTON (SW0)

MACHINE ON

RELAY (K4)

FRAME (FR)

OIL

ALERT

ENGINE START

ELECTROMAGNETIC

SWITCH (ES2)

ENGINE

SPARK PLUG (SPK)

ENGINE

P200128

Loading...

Loading...