INSTRUCTIONS FOR USE ENGLISH

14 664 7 2000 - S W 5 5 00, F L O O R T E C R 9 8 5 13

03/2016

TECHNICAL DATA (Continues)

Model SW5500 D SW5500 LPG -

FLOORTEC R 985 LPG

W e i g h t w e i g h t 7 5 7 K g 7 64 K g

t o t a l w e i g h t ( * ) 8 38 K g 8 7 1 K g

f r o n t a xl e w e i g h t ( * ) 35 4 K g 365 K g

r e a r a xl e w e i g h t ( * ) 4 8 4 K g 5 06 K g

g r o ss ve h i cl e w e i g h t ( G V W ) 1, 25 9 K g 1, 29 1 K g

heel specific pressure on the oor (front - rear wheels, in running conditions) 0. 7 - 0. 4 N /m m

2

0. 7 - 0. 5 N /m m

2

Sound pressure level at workstation (S 11201, S 4871, N 60335-2-72) (LpA) 8 4 d B ( A ) ± 3 d B ( A ) 7 9 d B ( A ) ± 3 d B ( A )

M a ch i n e so u n d p r e ssu r e l e ve l ( I S O 37 4 4 , I S O 4 8 7 1, E N 60335 - 2- 7 2) ( L w A ) 104 d B ( A ) 9 8 d B ( A )

I P p r o t e ct i o n cl a ss X 3

ust guard sstem water tank (optional) capacit 32 l i t r e s

U - t u r n sp a ce ( r i g h t - l e f t ) 2, 310 - 2, 37 5 m m

V i b r a t i o n l e ve l a t t h e o p e r a t o r ’ s a r m s ( I S O 5 34 9 - 1) ( * * ) < 2. 5 m /s

2

V i b r a t i o n l e ve l a t t h e o p e r a t o r ’ s b o d y ( I S O 2631- 1) ( * * ) 0. 8 m /s

2

( * ) ith operator on oard, fuel tank and hopper empt.

( * * ) nder normal working conditions, on a level asphalt surface.

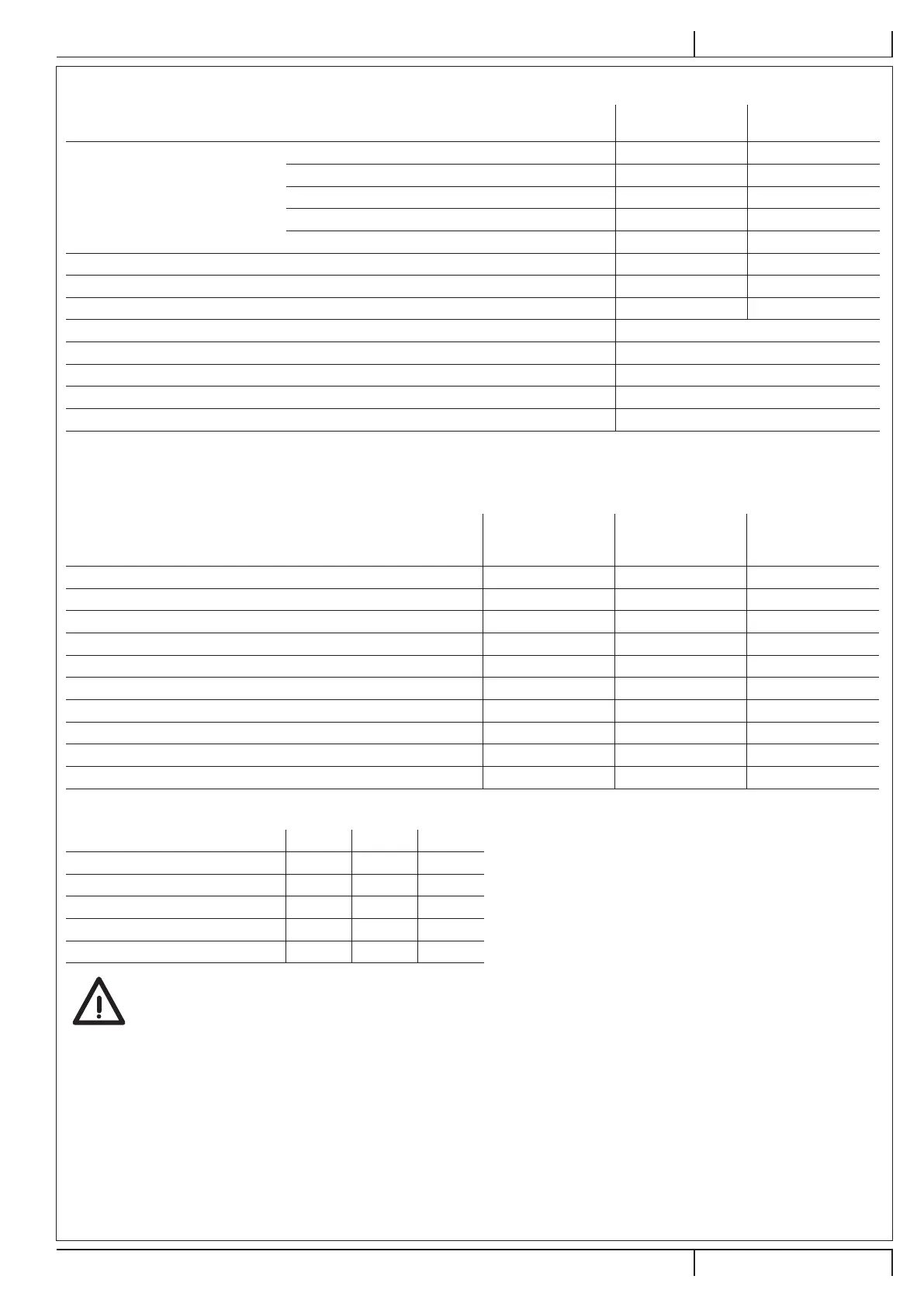

Machine Material Composition and Recyclability

Type

Recyclable

percentage

SW5500 D weight

percentage

Weight percentage

of the SW5500 LPG -

FLOORTEC R 985 LPG

A l u m i n i u m 100 % 0. 2 % 0. 1 %

E l e ct r i c m o t o r s - va r i o u s 29 % 15 . 1 % 20. 4 %

F e r r o u s m a t e r i a l s 100 % 65 . 6 % 61. 1 %

W i r i n g h a r n e sse s 8 0 % 0. 0 % 0. 0 %

L i q u i d s 100 % 0. 6 % 0. 6 %

P l a st i c - n o n - r e cycl a b l e m a t e r i a l 0 % 0. 0 % 0. 0 %

P l a st i c - r e cycl a b l e m a t e r i a l 100 % 1. 1 % 0. 8 %

P o l ye t h yl e n e 9 2 % 8 . 3 % 8 . 1 %

R u b b e r 20 % 9 . 0 % 8 . 7 %

C a r d b o a r d - p a p e r - w o o d 100 % 0. 2 % 0. 1 %

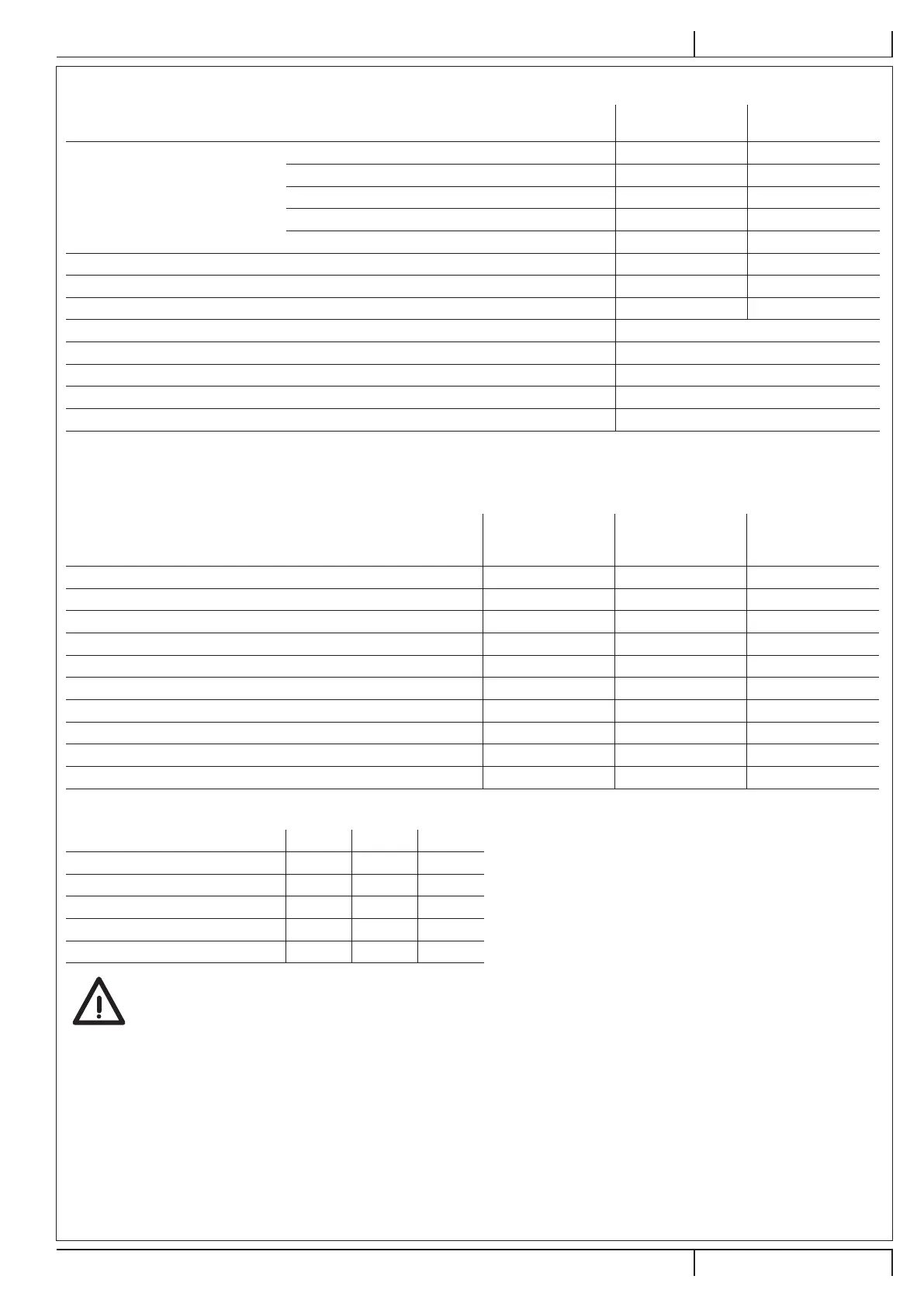

Hydraulic oil technical data

V i sco si t y a t 4 0 ° C m m

2

/s 45 32

V i sco si t y a t 100 ° C m m

2

/s 7 . 9 7 6. 4 0

V i sco si t y i n d e x / 15 0 15 7

F l a sh p o i n t C O C ° C 215 202

P o u r p o i n t ° C - 36 - 36

D e n si t y a t 15 ° C kg/l 0. 8 7 0. 8 65

CAUTION!

If the machine is to be used at ambient temperatures below +10 °C, the oil should be changed with equivalent oil

having a viscosity of 32 cSt. For temperatures below 0 °C, use an oil with lower viscosity.

Loading...

Loading...