INSTRUCTIONS FOR USE ENGLISH

14 664 7 2000 - S W 5 5 00, F L O O R T E C R 9 8 5 23

03/2016

AFTER USING THE MACHINE

After working, efore leaving the machine, perform the following procedures.

– Activate the filter shaker rie pressing the push-utton (57).

– E m p t y t h e h o p p e r ( 12) ( se e t h e p r o ce d u r e i n t h e p r e vi o u s p a r a g r a p h ) .

– R a i se t h e b r o o m s w i t h t h e O n e - T o u c h p u sh - b u t t o n ( 5 2) .

– (nl for LPG version). Close the safet valve on the LPG tank (32), then let the engine run until all the fuel is expelled from

t h e h o se s ( t h e n t h e e n g i n e i s st o p p e d ) .

– Turn off the machine turning the ignition ke (51) to 0, then remove it.

– ngage the parking rake.

N O T E

If the machine is left parked and inoperative, with the ignition key (51) in the “I” position, for more than 5 minutes, the

electrical system switches to a low power consumption mode (stand-by). To start work again, it is necessary to shut off

and restart the machine with the ignition key (51).

MACHINE LONG INACTIVITY

f the machine is not going to e used for more than 30 das, proceed as follows:

– P e r f o r m t h e p r o ce d u r e s sh o w n i n A f t e r M a ch i n e U se p a r a g r a p h .

– Check that the machine storage area is dr and clean.

– ( F o r D i e se l ve r si o n ) . C l o se t h e f u e l t a p ( 34 ) .

– (For LPG version). Close the LPG tank safet valve.

– D i sco n n e ct t h e n e g a t i ve co n n e ct o r ( - ) o f t h e b a t t e r i e s ( 4 6) .

– H a n d l e t h e e n g i n e ( 4 2) a s sh o w n i n t h e r e l e va n t M a n u a l .

– (For machines euipped with dust guard sstem). mpt the tank (23) and clean the water filter (see the procedure in

M a i n t e n a n ce ch a p t e r ) .

MAINTENANCE

T h e l i f e sp a n o f t h e m a ch i n e a n d i t s m a xi m u m o p e r a t i n g sa f e t y a r e e n su r e d b y co r r e ct a n d r e g u l a r m a i n t e n a n ce .

The following tale provides the scheduled maintenance. The intervals shown ma var according to particular working conditions,

which are to e defined the person in charge of the maintenance.

All scheduled or extraordinar maintenance procedures must e performed ualified personnel, or an authorised Service

C e n t e r .

CAUTION!

Each time the Service icon

is shown on the display (71), contact an authorised Nilsk Service Center for

scheduled maintenance.

T h i s M a n u a l d e scr i b e s o n l y t h e e a si e st a n d m o st co m m o n m a i n t e n a n ce p r o ce d u r e s.

F o r o t h e r m a i n t e n a n c e p r o ce d u r e s sh o w n i n t h e S ch e d u l e d M a i n t e n a n ce T a b l e , r e f e r t o t h e S e r vi ce M a n u a l t h a t ca n b e co n su l t e d

a t a n y S e r vi ce C e n t e r .

WARNING!

To perform maintenance procedures, the machine must be off, the ignition key removed, and, if necessary, the

batteries must be disconnected.

Read carefully the instructions in the Safety chapter before performing any maintenance procedure.

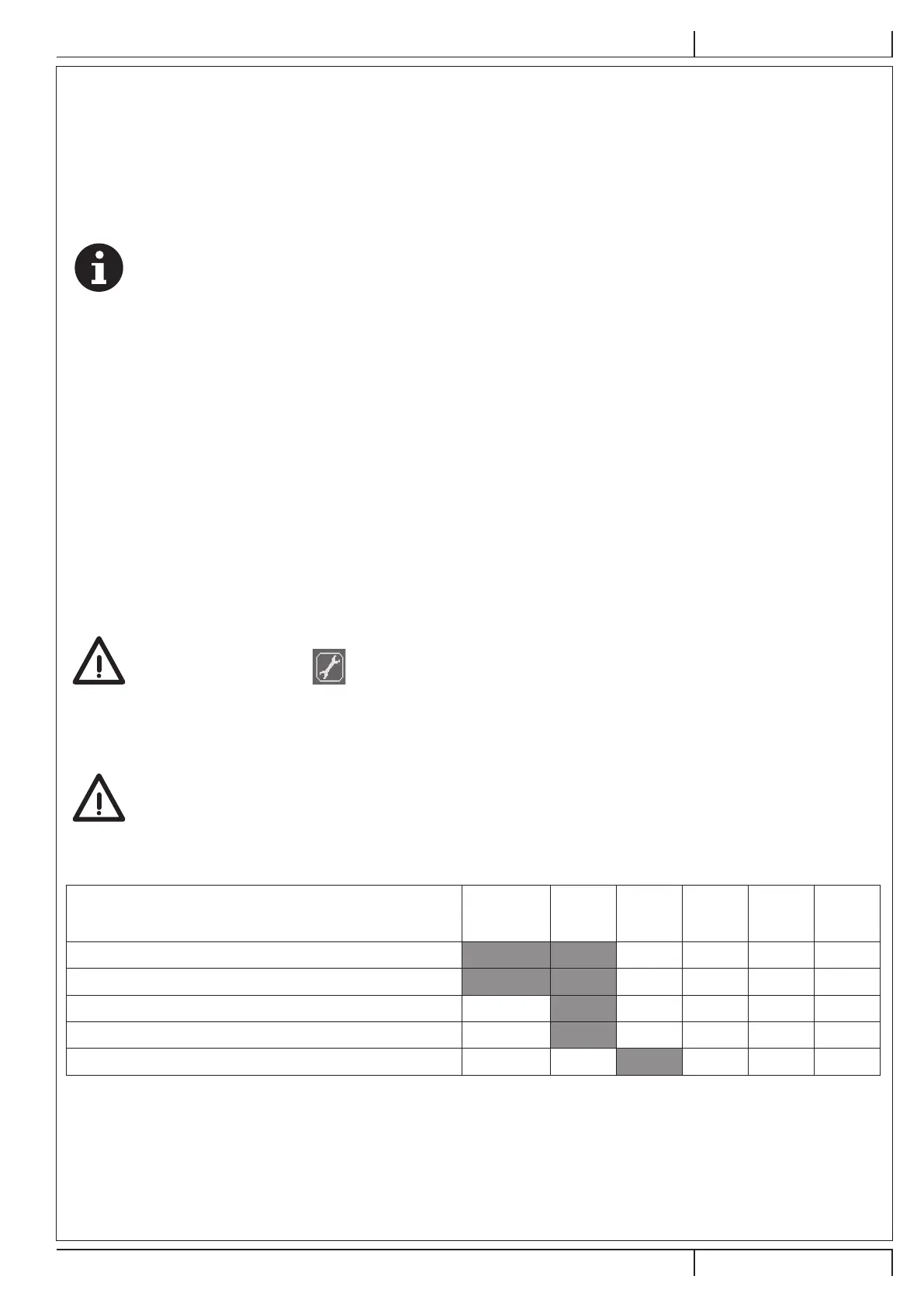

SCHEDULED MAINTENANCE TABLE

Procedure

Upon

delivery

Every 10

hours

Every 50

hours

Every

100

hours

Every

200

hours

Every

year

ngine oil level check ( 1)

Batter uid level check ( 2)

Side and main room height check

ngine air filter check ( 1)

opper dust filter check and cleaning (A method) ( 3)

Loading...

Loading...