15

3.4 Rotational speed and direction of rotation

This device may not be able to perform FFT analysis when rotational speed of the bearing is

extremely low or extremely high from the characteristic reason. Moreover, this device is applicable only

for the bearing with inner ring rotation for the detection of abnormality and the abnormality judgment

cannot be performed for the bearing with outer ring rotation.

3.5 Measuring method

Please note the following points when you set up this device. Improper set-up is the cause of correct

measurement being impossible.

3.5.1 Measurement condition

The vibration value and the bearing vibration frequency change depending on the use condition of the

bearing. For observing the change with time, please measure it under the same condition (bearing load,

rotational speed etc.) each time.

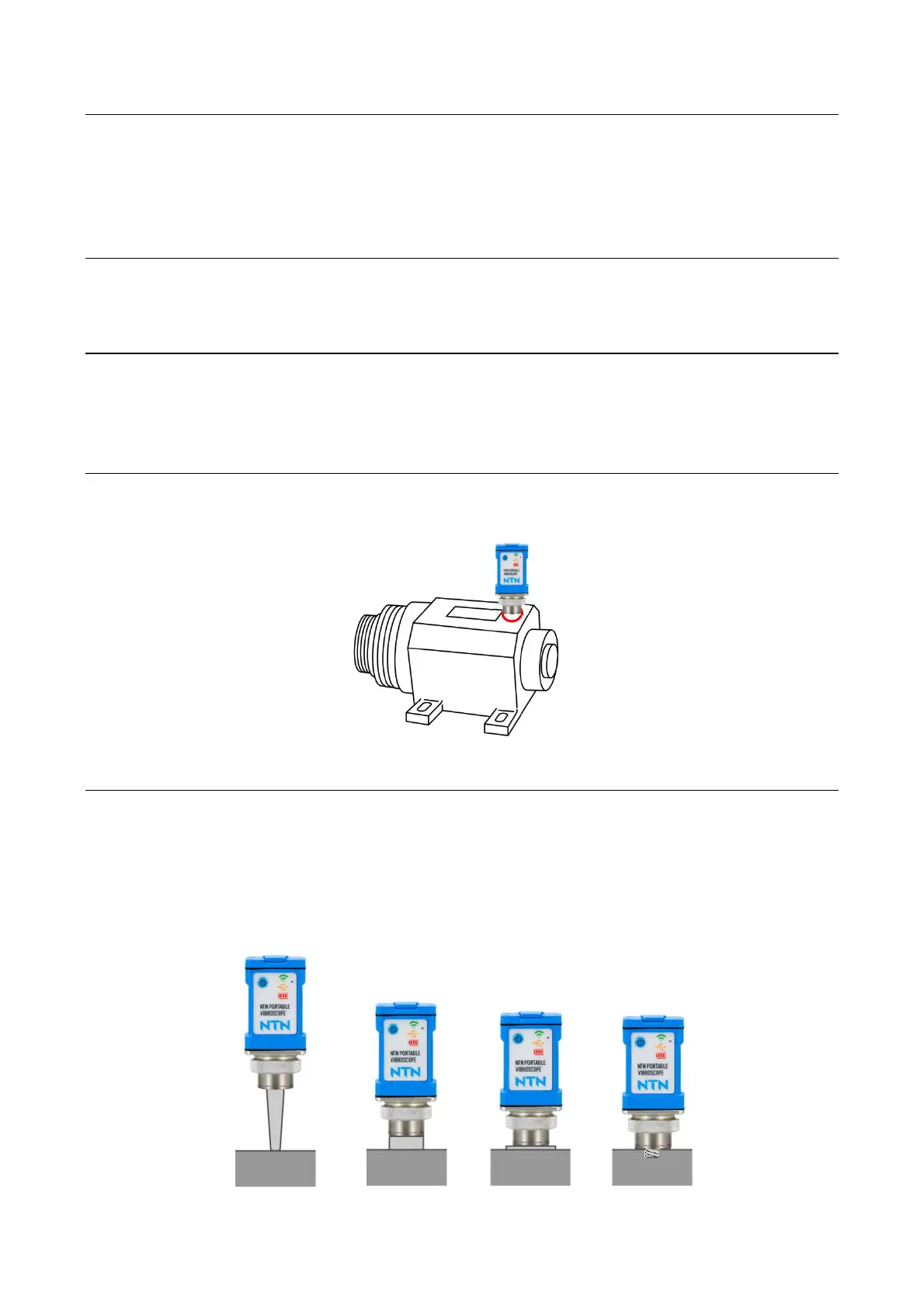

3.5.2 Measurement at the same position

The vibration has the direction of generation and it might be attenuated or amplified depending on the

measurement position. Therefore, when observing the change with time, please measure it by fixing the

device at the same position each time.

Figure 3.4 Measurement position

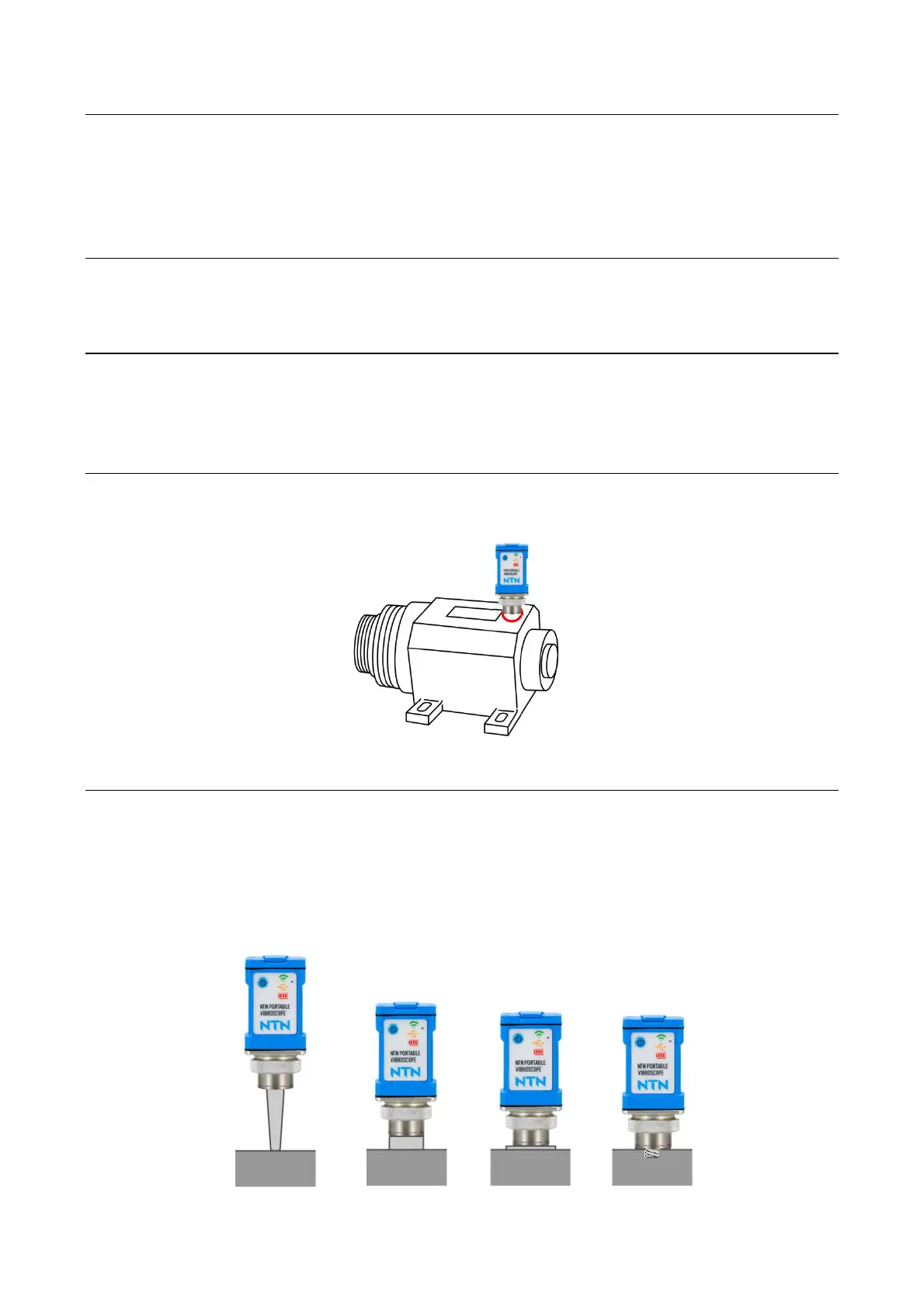

3.5.3 Contact resonance

Please use the attached magnet for fixing this device. While the contact pin can be used to measure

easily, the measured vibration is amplified or attenuated from the actual value, depending on the

frequency, and therefore high measurement accuracy cannot be obtained. Moreover, when the

equipment to be measured has a screw hole of M6xP1, the set bolt (length: about 10 mm) is used to fix

the device such that the end face of acceleration pick-up and the surface of the equipment to be measured

come to close contact with each other, then the higher accuracy of the measurement is possible.

Contact pin Magnet Double-faced tape Screwing

Figure 3.5 Fix method of this device

Loading...

Loading...