HeatWater.com | WaterService@nyle.com | (800) 777-6953 IM-e360-122023 IM-e360-122023 HeatWater.com | WaterService@nyle.com | (800) 777-6953

35

Startup Procedure and Checklist (Continued)

F For Ducted Systems: Ensure any dampers

in the duct system are open, and if ducting is

shared between multiple heat pumps, then all

heat pumps on the duct system should be run

and measured together. Initiate “Max Fan” on

the control interface, in the “Diagnose” section

(service jumper required on terminals 24V and

i7). Using a manometer or magnahelic gauge,

take a negative pressure reading in the intake

duct near the evaporator, and a positive pres-

sure reading in the discharge duct near the fan

housing. Seal access holes when done. The

difference between the two readings should not

exceed 1.5" w.c.g.

Measured Discharge

______________ In. w.c.g.

Measured Intake

______________ In. w.c.g.

F Power down the heat pump. Locate the defrost

heater contactor in the electrical enclosure.

Measure the resistance between the terminals

listed in Table 12 and ensure resistance is within

+5% or -10% of the listed value. If not, it will be

necessary to locate any bad elements.

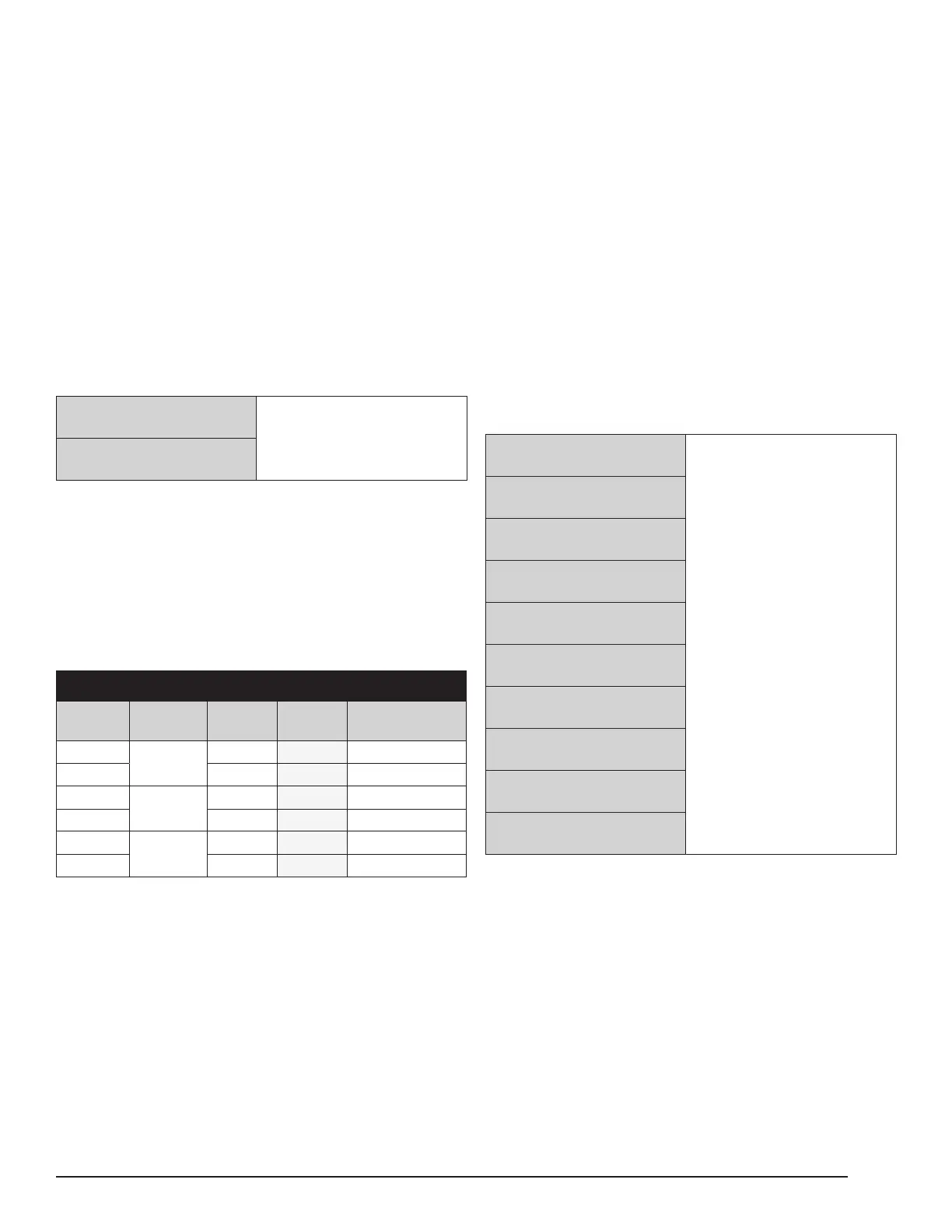

Table 12: Defrost Element Resistance Values

Ohms Between Contactor Terminals

Heat

Pump

Terminals Target Actual

Ohms

Single Element

230V

T1-T2

5.9 44

460V 25.6 64

230V

T2-T3

5.9 44

460V 25.6 64

230V

T1-T3

5.9 44

460V 25.6 64

Note: At this point if all Pre-Startup and Startup procedures

and checks have been completed, it is safe to turn the heat

pump “ON” via the control interface, which will enable nor-

mal compressor operation.

F Double check that all conguration options on

the control interface are set as required for this

project.

F Typically, a demand for heating should start, as

the tanks should be cold. If not, dump hot water

until a demand is initiated. If BMS control is in-

volved, ensure that BMS has not “disabled” the

heat pump.

F Wait a total of 20 minutes before taking the fol-

lowing operational readings after a heat demand

initiates. This includes several minutes of startup

delay before compressor operation begins, and

several more minutes of continuous operation.

Pressures and readings should be somewhat

stable before readings are taken.

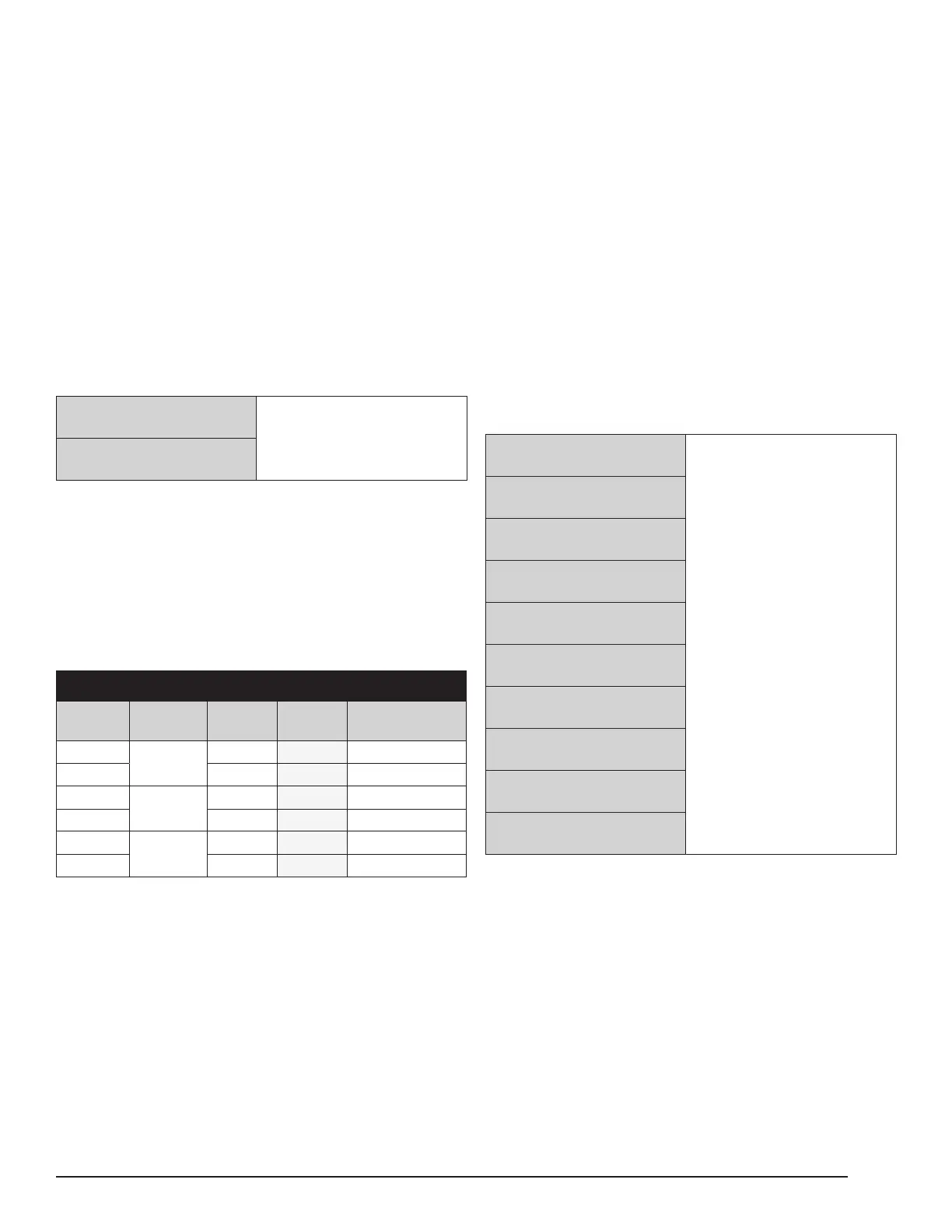

F Record the following readings from the control

interface:

Condenser Flow Rate

______________ GPM

Ambient Temperature

______________ Deg. F.

Condenser EWT

______________ Deg. F.

Condenser LWT

______________ Deg. F.

Superheat

______________ Deg. F.

Discharge Temperature

______________ Deg. F.

Liquid Line Temperature

______________ Deg. F.

Suction Temperature

______________ Deg. F.

Suction Line Pressure

______________ psi

Discharge Line Pressure

______________ psi

Loading...

Loading...