BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 45 of 76

7 Heating system

The heating water and system pressure should be

checked regularly by the system operator and

corrected in case of deviations (pressure too

high/low). The flow rates at the heat sink system

(WNA) are monitored by the integral flow sensor.

The specified system maintenance intervals and

system checks must also be observed.

If major modifications or pipe breakages require

draining and subsequent replacing of a large

proportion of the heating water, this should be

done in the presence of OCHSNER customer

service or by an authorised OCHSNER authorised

partner (see enclosed logbook). In the case of non-

routine refilling (e.g. after modifications or pipe

breakages), a current water assessment must be

prepared, and, on the basis of this, the heat sink

system must be refilled, with additives if required,

by the installer.

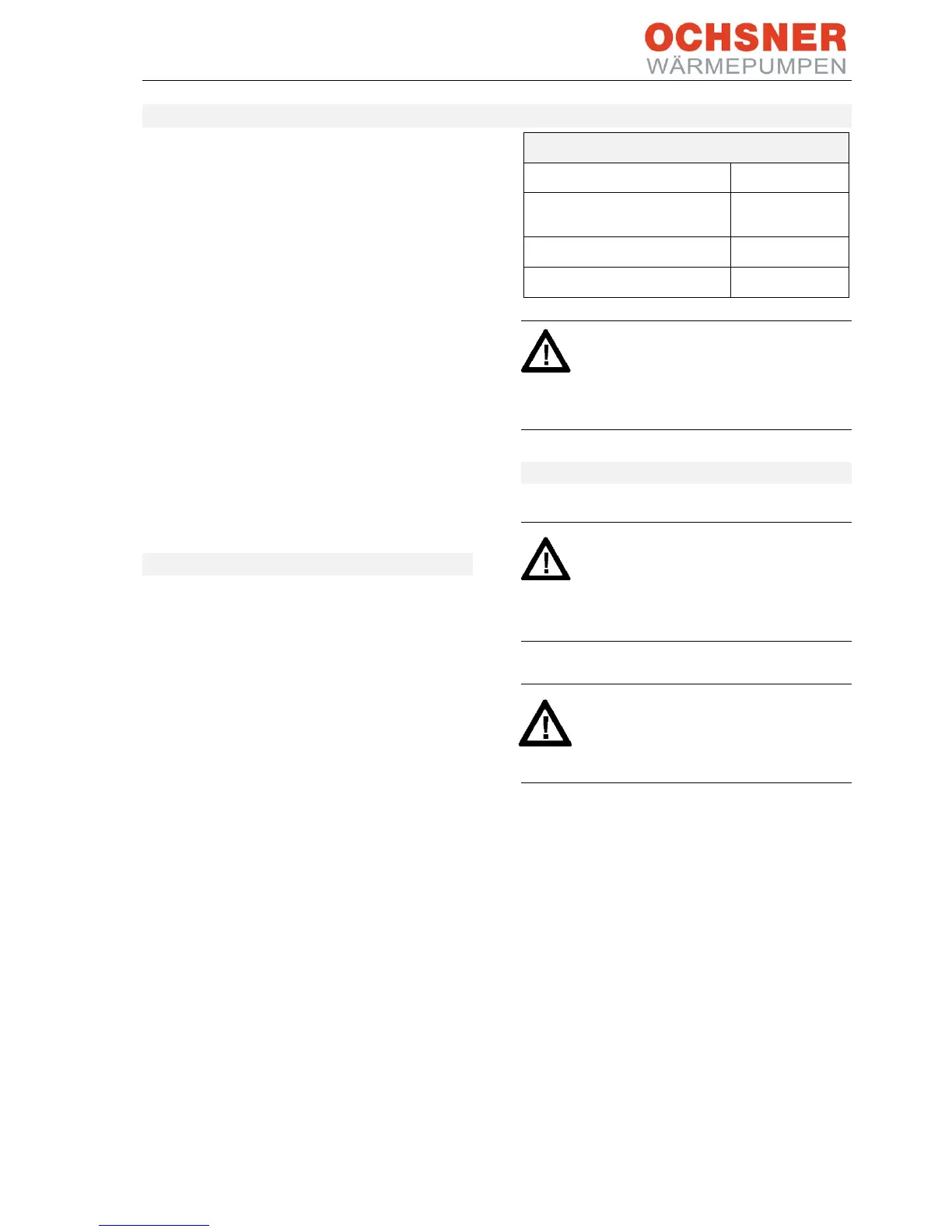

7.1 Quality of heating water

Use the correct fill water that is suitable for the

components of your heating system. We

recommend fill water prepared according to

Guideline VDI 2035-2.

A high pH value and low electrical conductivity in

the fill water will reduce to a minimum the risk of

corrosion to iron and copper materials, as long as

there is also low oxygen content. This will also

minimise scaling (calcification).

Unsuitable fill water can damage your

system due to scaling and corrosion. If

necessary, ensure that the fill water is

professionally softened and

demineralised.

7.2 Pressure maintaining system

For the operational reliability of your

system in defrosting or cooling mode, it

is important that the hydraulic safety

and pressure maintaining devices are

sufficiently sized and inspected annually

according to the relevant standards.

CAUTION

The closures provided are only for

transport. Replace them with suitable

plugs if the DHW flow or return is not

being used!

Loading...

Loading...