A

Appendix

A-4 CP1L Programming Examples

SYSMAC CP1L/CP1E Introduction Manual 157

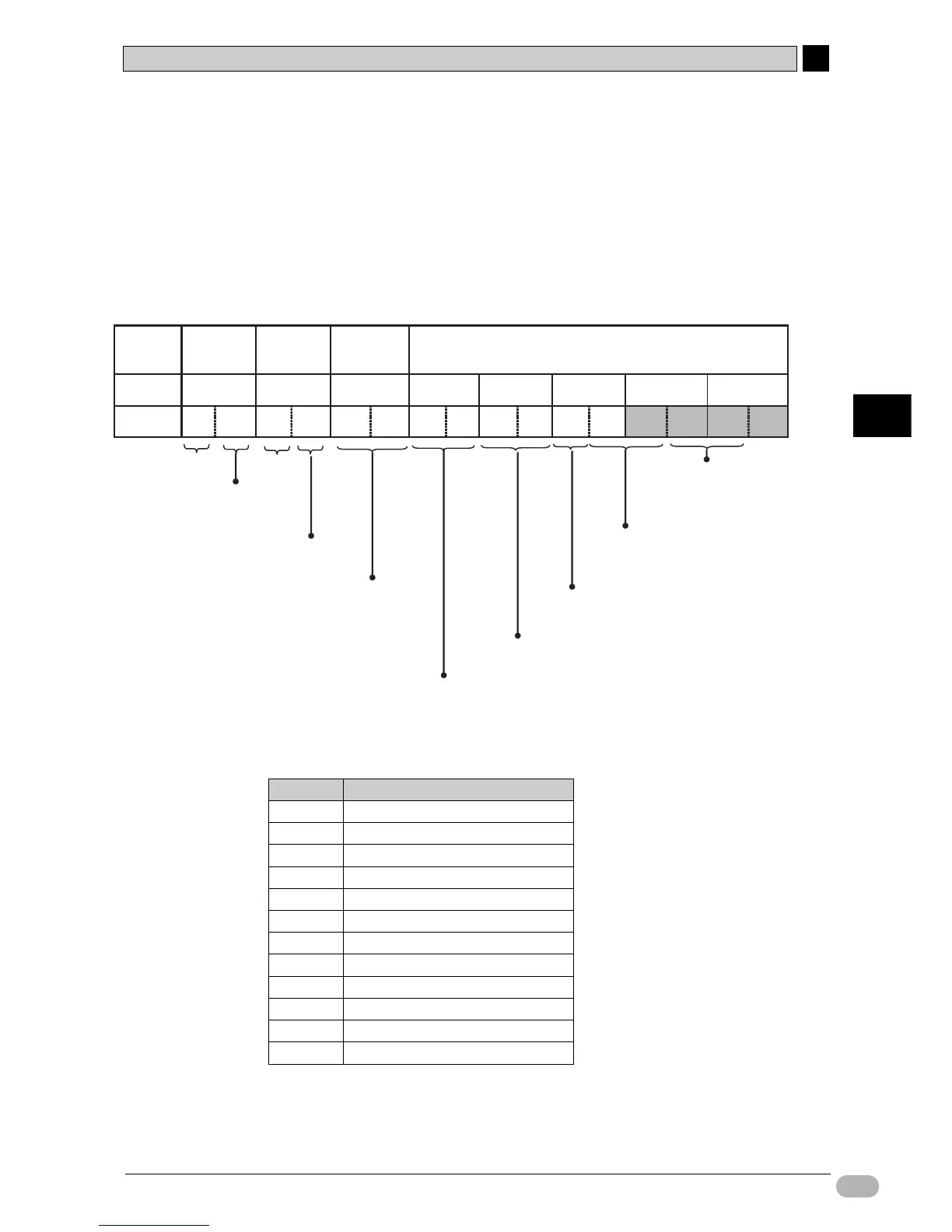

●DM Area Setup

• DM Fixed Allocation Words for Modbus-RTU Easy Master

DM settings from D32300 to D32305 (CP1E: D1201 to D1205) are set before the

execution of the ladder program.

D32306 and D32307 (CP1E: D1206 and D1207) do not need to be set explicitly.

They are modified by MOV instructions, and are used to change, start, and stop

frequency commands.

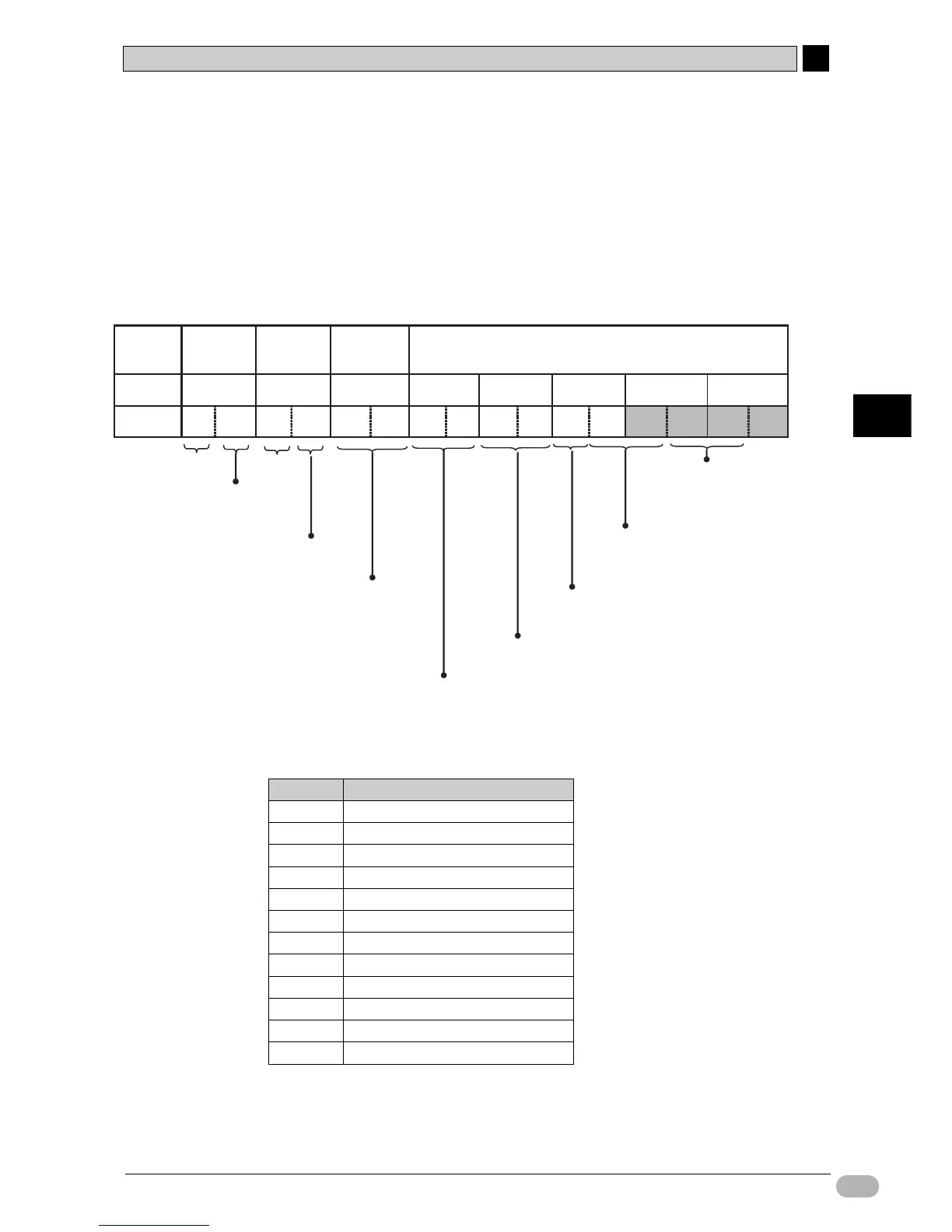

• Operation Command (Register No.0001 Hex) allocation and details for

Inverter V1000

For this example, only operation command (No.0 bit) will be used.

• With Modbus-RTU easy master function, CRC-16 checksums do not need to be

set in the DM area, since they are calculated automatically.

00

D3230

4

(CP1E: D1204)

0100

D32303

(CP1E: D1203)

0900

D32302

(CP1E: D1202)

1000

D32301

(CP1E: D1201)

01

00

D32300

(CP1E: D1200)

02

01

D32306

(CP1E: D1206)

0004

D32305

(CP1E: D1205)

02

58

D32307

(CP1E: D1207)

02 58

Communication data: D32303 to Max. D32349

(CP1E: D1203 to Max. D1249)

FUNCTION

code

Address

00

00

Number of registers data is written to: 2

(2 data: No.0001 and No.0002 on register 2)

Communication

data bytes

Slave

address

Setting

Value

Inverter slave address: 1 (Hex)

Inverter data write: 10 (Hex)

For number of bytes, use 9 bytes from

upper D32303 to upper D32307

(CP1E: Upper D1203 to upper D1207)

Serial Port 1: Command

Register No. for starting data write:0001

(start writing to inverter at register No.0001)

Attached data size in bytes: 4

(4 bytes from lower D32305 to upper D32307

(CP1E: lower D1205 to upper D1207))

Data for starting register

(e.g. set 0001 Hex for No.0001

[operation command (see below)])

Data for next register

(e.g. set 60.0Hz (0258 Hex) for No.0002

[frequency command])

Bit No. Setting

0 Operation command (1: Start)

1 Normal/reversed rotation (1: Reversed)

2 External error (1: EF0)

3 Error reset (1: Error reset)

4 Multifunction input 1 (1: ON)

5 Multifunction input 2 (1: ON)

6 Multifunction input 3 (1: ON)

7 Multifunction input 4 (1: ON)

8 Multifunction input 5 (1: ON)

9 Multifunction input 6 (1: ON)

A(Unused)

B to F (Unused)

Loading...

Loading...