26

Initial Setting Examples Section 3-1

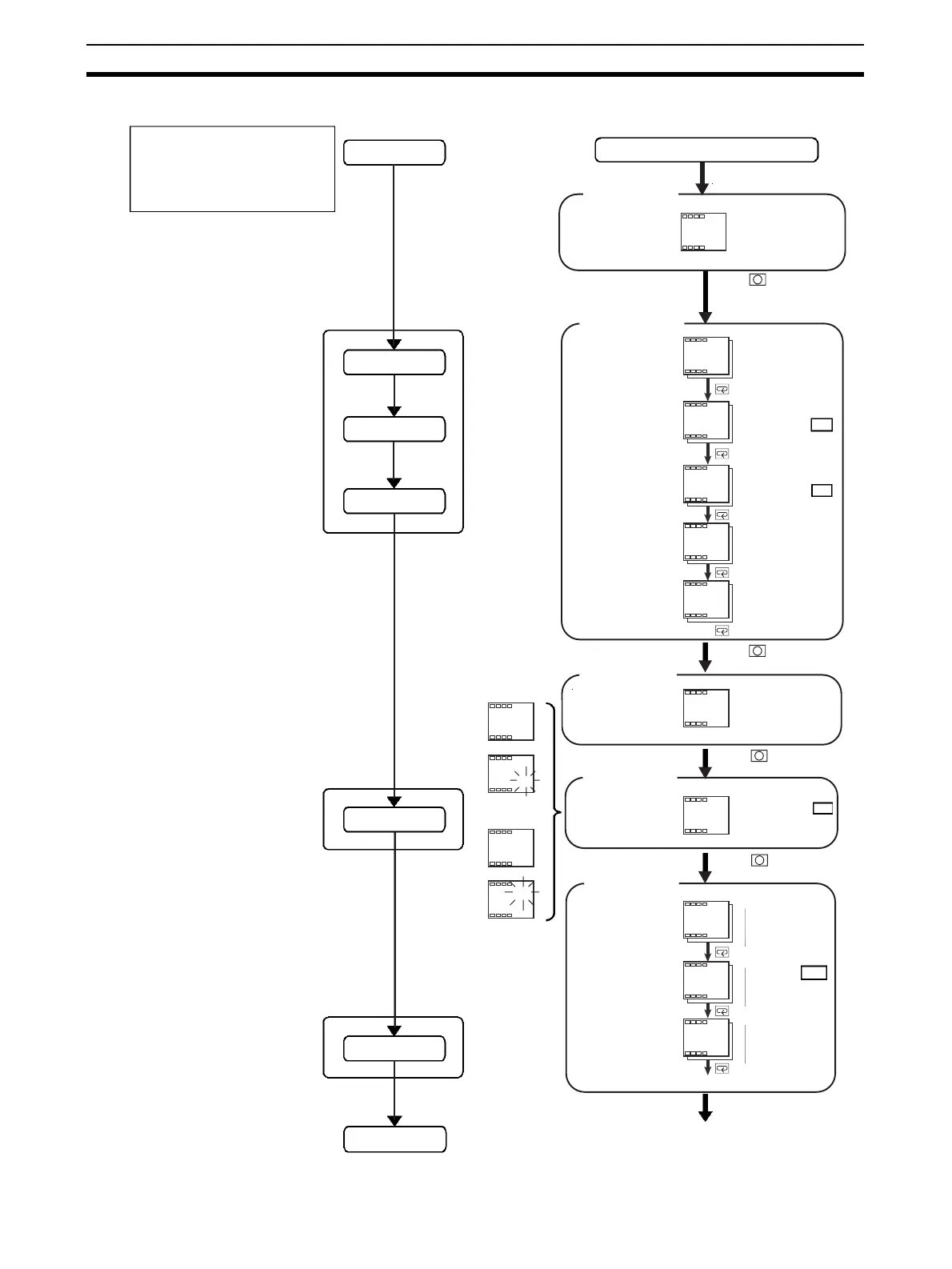

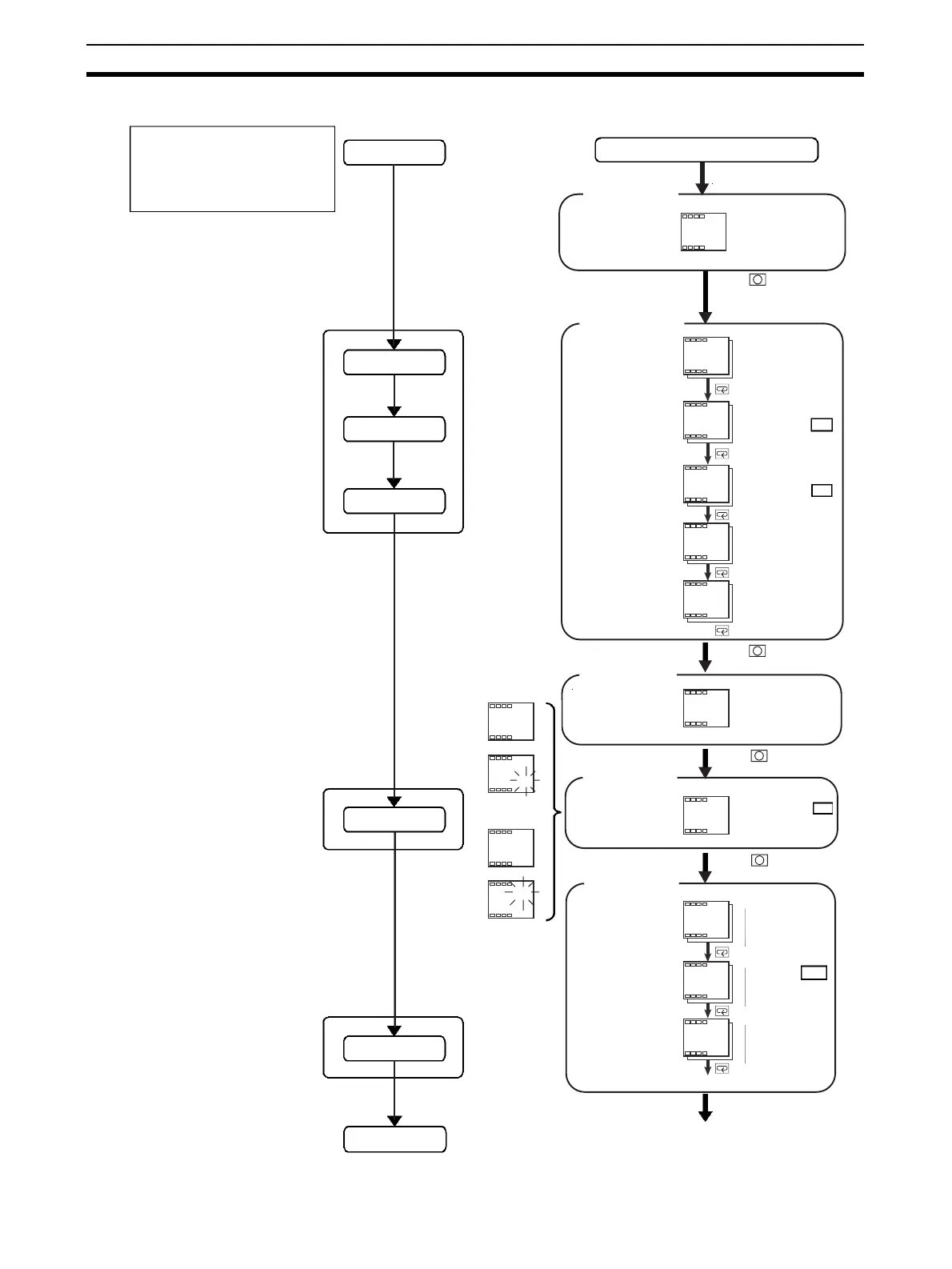

Typical example 2

Setup procedure

Power ON

Initial setting level

Set alarm type

AT execution

Set alarm values

Adjustment level

Operation level

(when PID

control is

selected)

Start operation

Power ON

Process value/

set point

Check alarm

type.

Start program execution

Input type: 9 T thermocouple −200 to 400°C

Control method: PID control

Calculate PID constants by AT (auto-tuning)

execution.

Alarm type: 2 upper limit

Alarm value 1: 30°C (deviation)

Set point: 150°C

Set input

specifications

Set control

specifications

While AT is being

executed, SP will flash

After AT execution

Press DU keys

to set alarm value

to "30°C".

Make sure that

control is

running.

Alarm value 1 30

30

al-1

During run

During stop

run

stop

run

r-5

Process value/

set point 150

150

25

Make sure

that set point

is "150°C".

Execute AT

(auto-tuning).

To execute AT

To cancel AT

on

off

off

at

150

25

Press DU keys

to set point to

"150°C".

Process value/

set point

150

Alarm 1 type

2

2

alt1

Check the

control period.

Press DU keys

to set ST to OFF.

Control period

(heat) (unit:

seconds)

20

20

cp

To execute ST

To cancel ST

on

off

off

st

Press DU keys

to set PID control.

In ON/OFF

control

In PID control

onoff

pid

pid

cntl

Press DU keys

to select input

type.

Input type

9

Press key for at

least three seconds.

Control stops.

9

in-t

0

25

Operation level

Initial setting level

Operation level

Adjustment level

Operation level

During AT execution

During AT execution

After AT execution

PV/SP

Press key for

less than 1 second.

Press key for

less than 1 second.

Press key for at

least one second.

in-t

9

cntl

pid

st

off

cp

20

25

150

r-5

run

al-1

30

alt1

2

25

150

C

at

off

25

0

C

25

150

C

at

off

at

on

26

150

C

Loading...

Loading...