Precautions for Correct Use

If you are using the measurement results of the Sensor Controller to operate an external de-

vice, make sure the movement is within the range of the movement of the external device be-

fore you implement the move.

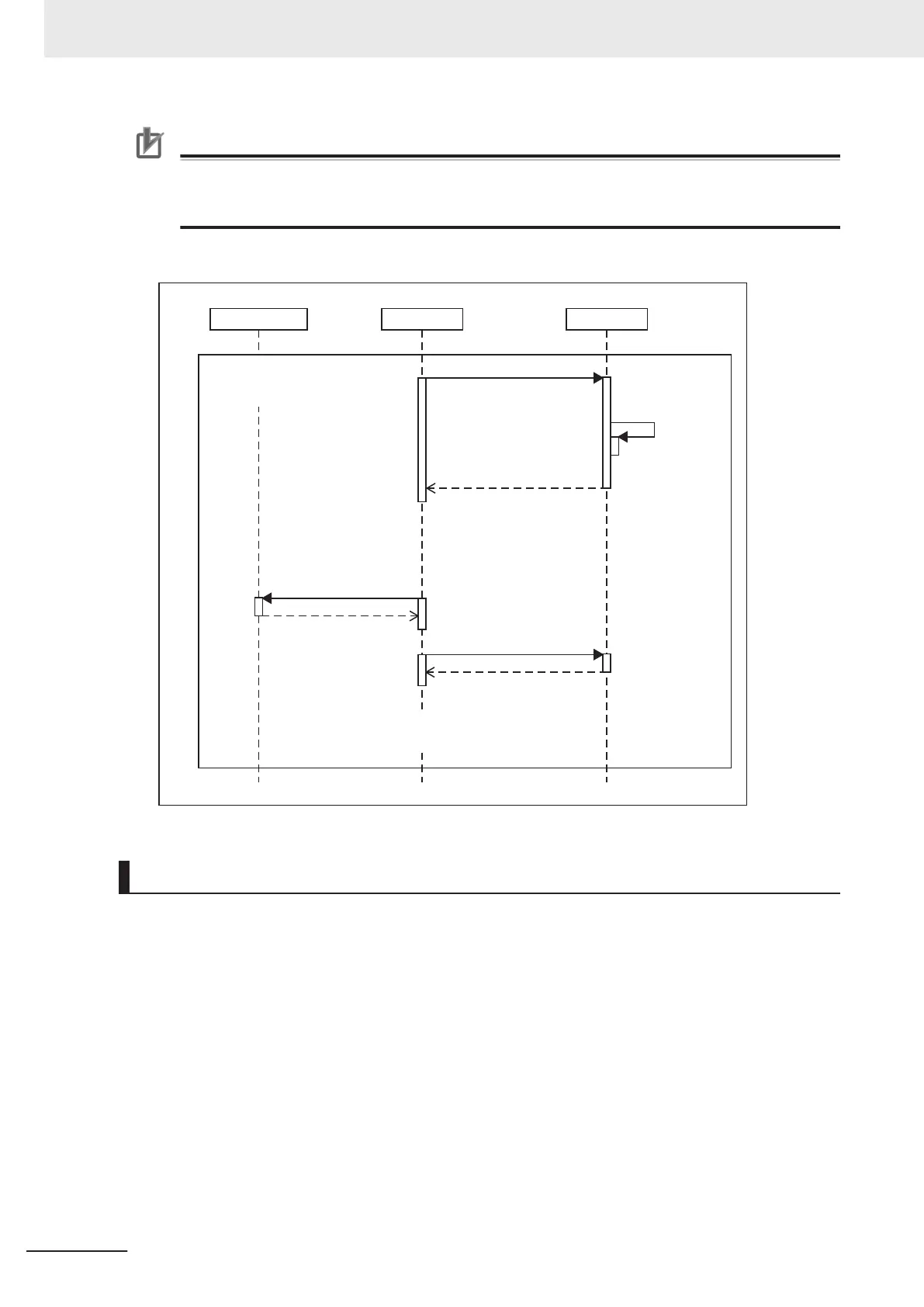

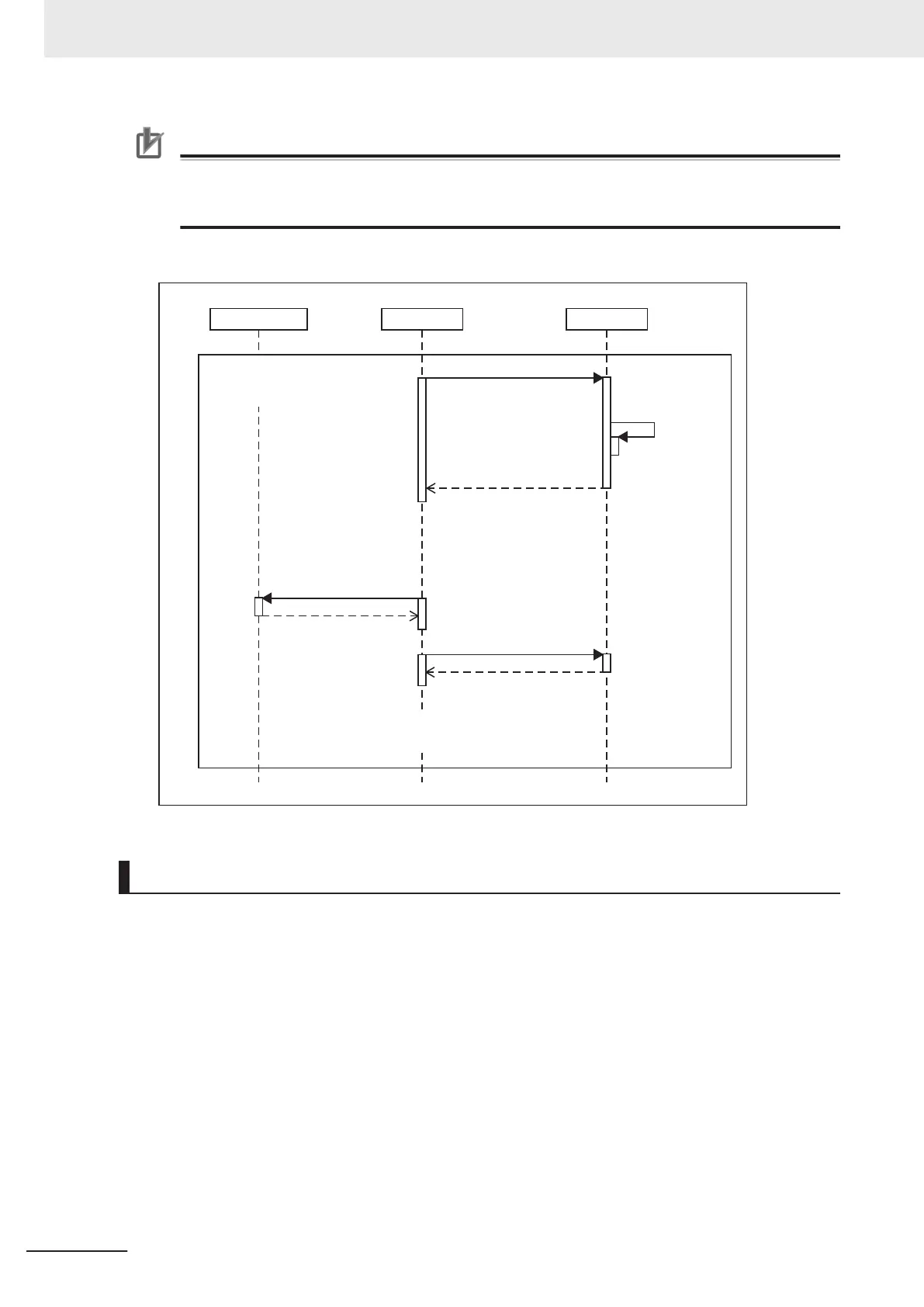

Executing Alignment:

External device

PLC

FH/FHV

1: Measurement request

1.1: Measurement

processing

Data output

Move completion response

3: Set the current axis position

Setting completion response

If the position difference is greater

than the threshold, the processing in

the frame is repeated.

2: Move each axes by the

amount of the axis

movement.

Processing exits the loop if the

position difference is less than or

equal to the threshold.

• Axis movement (for the

number of axes on the

external device)

• Position XY differences

• Angular position difference

Other Alignment Functions

l

When failed to measure such as an alignment mark, an operator directly

and manually specifies the coordinates [Manual Position Setting]

When failed to measure such as an alignment mark, an operator can specify the coordinates man-

ually and directly by using the Manual Position Setting processing unit function in combination with

a processing unit such as Search to detect an alignment mark.

There are two ways to launch the Manual Position Setting function.

• Communication command startup:

Higher-level devices such as PLC check a transmitted measurement data from the Sensor con-

troller. If the Position Setting Request flag was set, then the device judge the measurement failed

and send a measurement command for re-measurement. The command opens the Manual

Position Setting screen.

• Auto startup during measurement:

10 Advanced Usage

10 - 64

FH/FHV Series Vision System User’s Manual (Z365-E1)

Loading...

Loading...