4-6

INITIAL SETTING

"Pulse frequency", "scaling

factor", and "decimal point

position" should be set in this

order.

Otherwise, auto-initialization

of parameters may result in a

failure in parameter setting.

If you specify the scaling

factor and then the pulse

frequency, the scaling factor

is initialized automatically.

CHAPTER 4 INITIAL SETTING

4-3 K3MA-F (Frequency/Rate meter)

The following example shows the flow of initial setting for K3MA-F.

How to Determine the Scaling Factor

Determine the scaling factor as follows.

Rotor rotational speed (r/min)

=Input frequency (Hz) /Number of pulses per rotation × 60

Belt speed (m/min) = π × Rotor diameter (m) × Rotational speed (r/min)

Hence the speed is given as

Belt speed (m/min) = 3.14159••• × 0.12 × 60/4× Input frequency (Hz).

Namely,

Belt speed (m/min) = 5.654866••• × Input frequency (Hz).

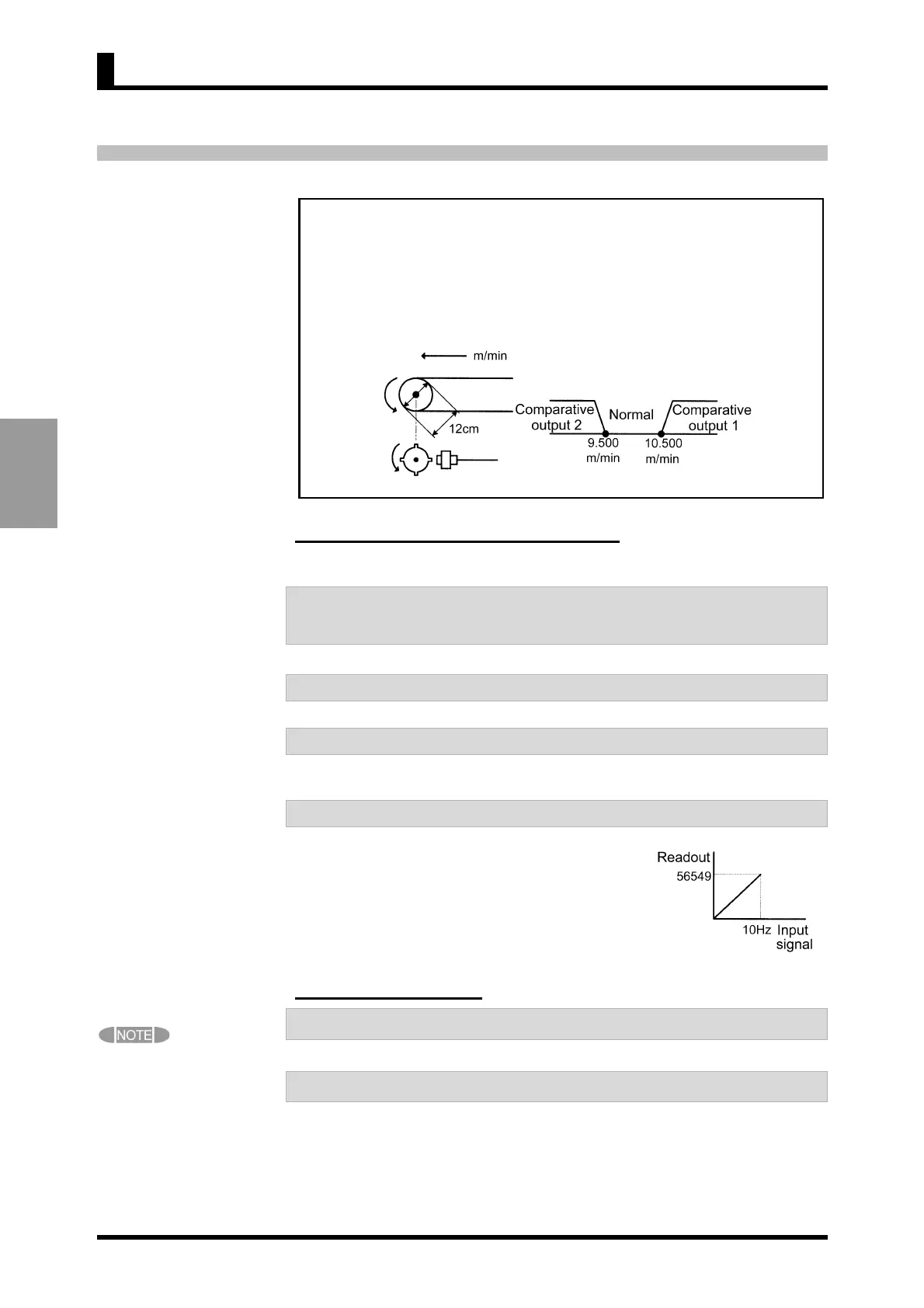

Multiply the result by 1000 to enable a readout to be displayed to three decimal

places.

Belt speed (m/min) = 5654.866••• × Input frequency (Hz).

To minimize the scaling operation error, select a

convenient numerical value for the scaling input value

and such a combination of input value and readout that

allows readouts to contain the largest possible number

of digits. In this example, the input frequency is set to

10 Hz so that the readout is 56549.

Flow of Initial Setting

A. Check wiring for correct connection and power the product on.

The product is factory set to have a pulse frequency of 5 kHz.

B. Set "pulse frequency" to "30 Hz".

<Setting example>

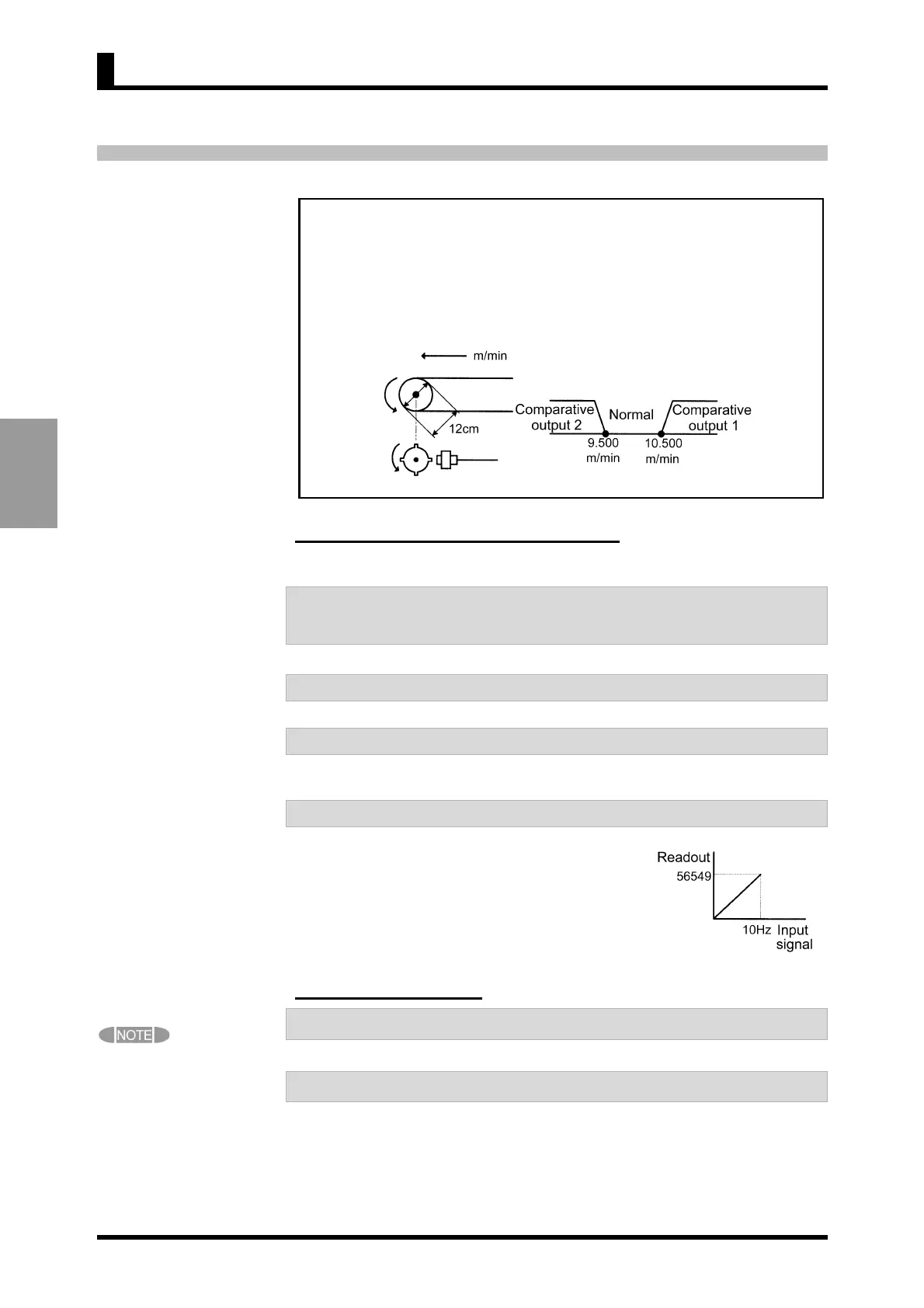

The speed of a belt conveyer is indicated with the unit of m/min.

The number of pulses per one rotation of the rotor is 4.

The diameter of the rotor is 12 cm.

When the process value reaches 10.500 m/min, comparative output 1 is pro-

duced.

When the process value decreases to 9.500 m/min, comparative output 2 is

produced.

Loading...

Loading...