1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

Remove the capscrews that secure the noise

shield (see Figure 6-4) to the engine and lift

off

the noise shield.

Remove the three nuts (located along the lower

edge of the scroll) that fasten the flywheel guard

to the scroll.

Remove the capscrews that fasten the scroll to

the backplate and lift away from the scroll.

Remove the screws that fasten the cylinder air

housings to the backplate and cylinder heads and

lift off the air housings.

Loosen the flywheel capscrew and back it out

several turns.

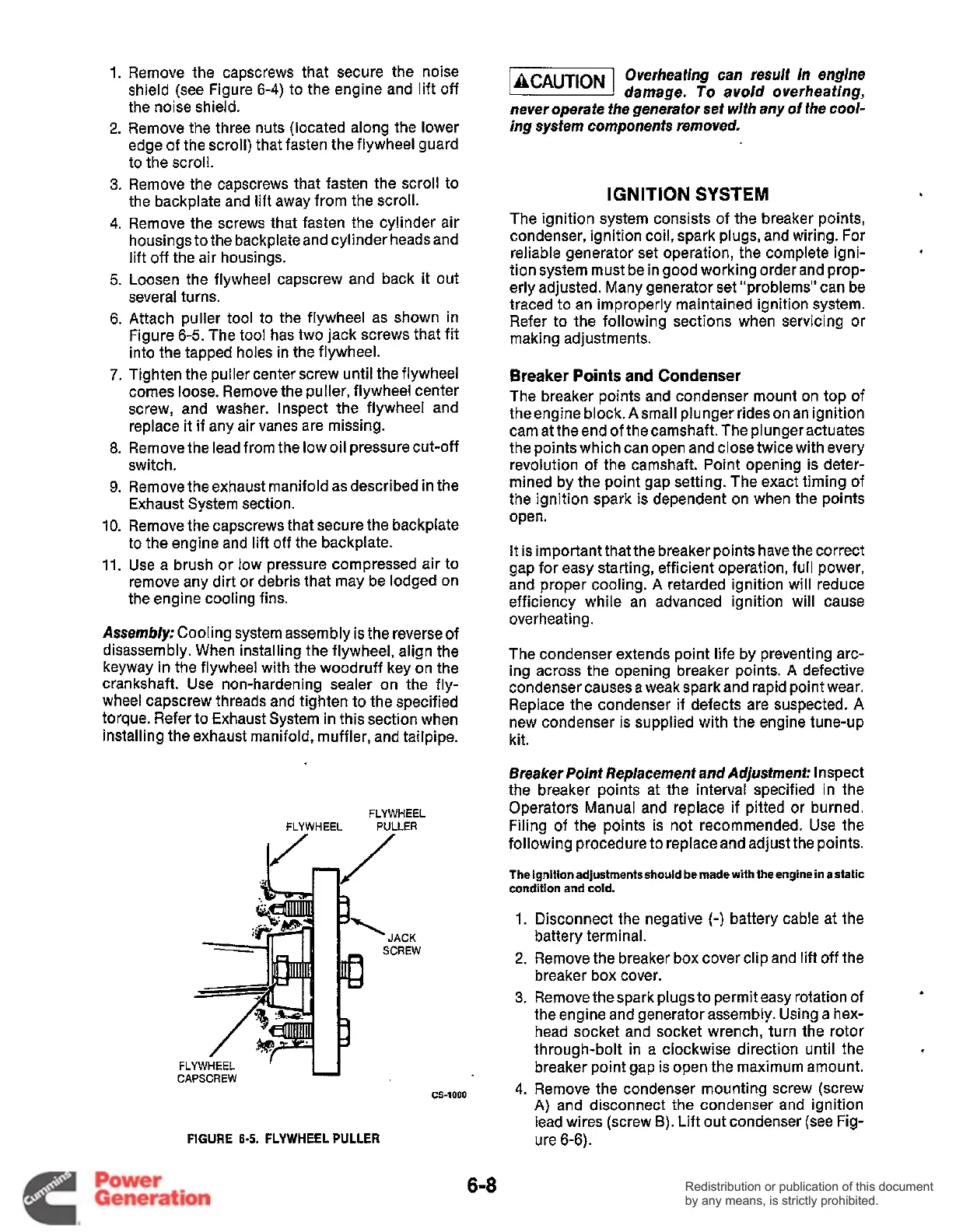

Attach puller tool to the flywheel as shown in

Figure 6-5. The tool has two jack screws that fit

into the tapped holes in the flywheel.

Tighten the puller center screw until the flywheel

comes loose. Remove the puller, flywheel center

screw, and washer. Inspect the flywheel and

replace

it

if any air vanes are missing.

Remove the lead from the low oil pressure cut-off

switch.

Remove the exhaust manifold as described in the

Exhaust System section.

Remove the capscrews that secure the backplate

to the engine and lift off the backplate.

Use a brush or low pressure compressed air to

remove any dirt or debris that may be lodged on

the engine cooling fins.

Assembly:

Cooling system assembly is the reverse of

disassembly. When installing the flywheel, align the

keyway in the flywheel with the woodruff key on the

crankshaft. Use non-hardening sealer on the fly-

wheel capscrew threads and tighten to the specified

torque. Refer to Exhaust System in this section when

installing the exhaust manifold, muffler, and tailpipe.

FLYWHEEL

FLYWHEEL

PULLER

FLYWHEEL

‘

CAPSCREW

cs-1000

FIGURE

6-5.

FLYWHEEL PULLER

-1

Overheating can result in engine

damage.

To

avoid overheating,

never operate the generator set with any

of

the cool-

ing system components removed.

IGNITION

SYSTEM

The ignition system consists of the breaker points,

condenser, ignition coil, spark plugs, and wiring. For

reliable generator set operation, the complete igni-

tion system must be in good working order and prop-

erly adjusted. Many generator set “problems” can be

traced to an improperly maintained ignition system.

Refer to the following sections when servicing or

making adjustments.

Breaker Points and Condenser

The breaker points and condenser mount on top of

theengine block. Asmall plunger rides on an ignition

cam at the end of the camshaft. The plunger actuates

the points which can open and close twice with every

revolution of the camshaft. Point opening is deter-

mined by the point gap setting. The exact timing of

the ignition spark is dependent on when the points

open.

It

is important that the breaker points have the correct

gap for easy starting, efficient operation, full power,

and proper cooling. A retarded ignition will reduce

efficiency while an advanced ignition will cause

overheatina.

The condenser extends point life by preventing arc-

ing across the opening breaker points.

A

defective

condenser causes a weak spark and rapid point wear.

Replace the condenser if defects are suspected.

A

new condenser is supplied with the engine tune-up

kit.

Breaker

Point

Replacement and Adjustment:

Inspect

the breaker points at the interval specified in the

Operators Manual and replace if pitted or burned.

Filing of the points is not recommended. Use the

following procedure to replace and adjust the points.

The ignition adjustmentsshouid be made with the engine in a static

condition and cold.

1.

Disconnect the negative

(-)

battery cable at the

battery terminal.

2.

Remove the breaker box cover clip and

lift

off the

breaker box cover.

3.

Remove the spark plugs to permit easy rotation of

the engine and generator assembly. Using a hex-

head socket and socket wrench, turn the rotor

through-bolt in a clockwise direction until the

breaker point gap is open the maximum amount.

4. Remove the condenser mounting screw (screw

A)

and disconnect the condenser and ignition

lead wires (screw

B).

Lift

out condenser (see Fig-

ure

6-6).

6-8

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

Loading...

Loading...