the specified amount.

Do

not hammer

the

new

pin

into place or it will be damaged. The camshaft center

pin cannot be pulled outward nor removed without

damage.

If

the

center

pin

extends

out

too far,

the

cup

will

not hold the flyballs.

TIMING

GEARS

AND CAMSHAFT

If replacement of either the crankshaft gear or the

camshaft gear becomes necessary, it is recom-

mended that both gears be replaced.

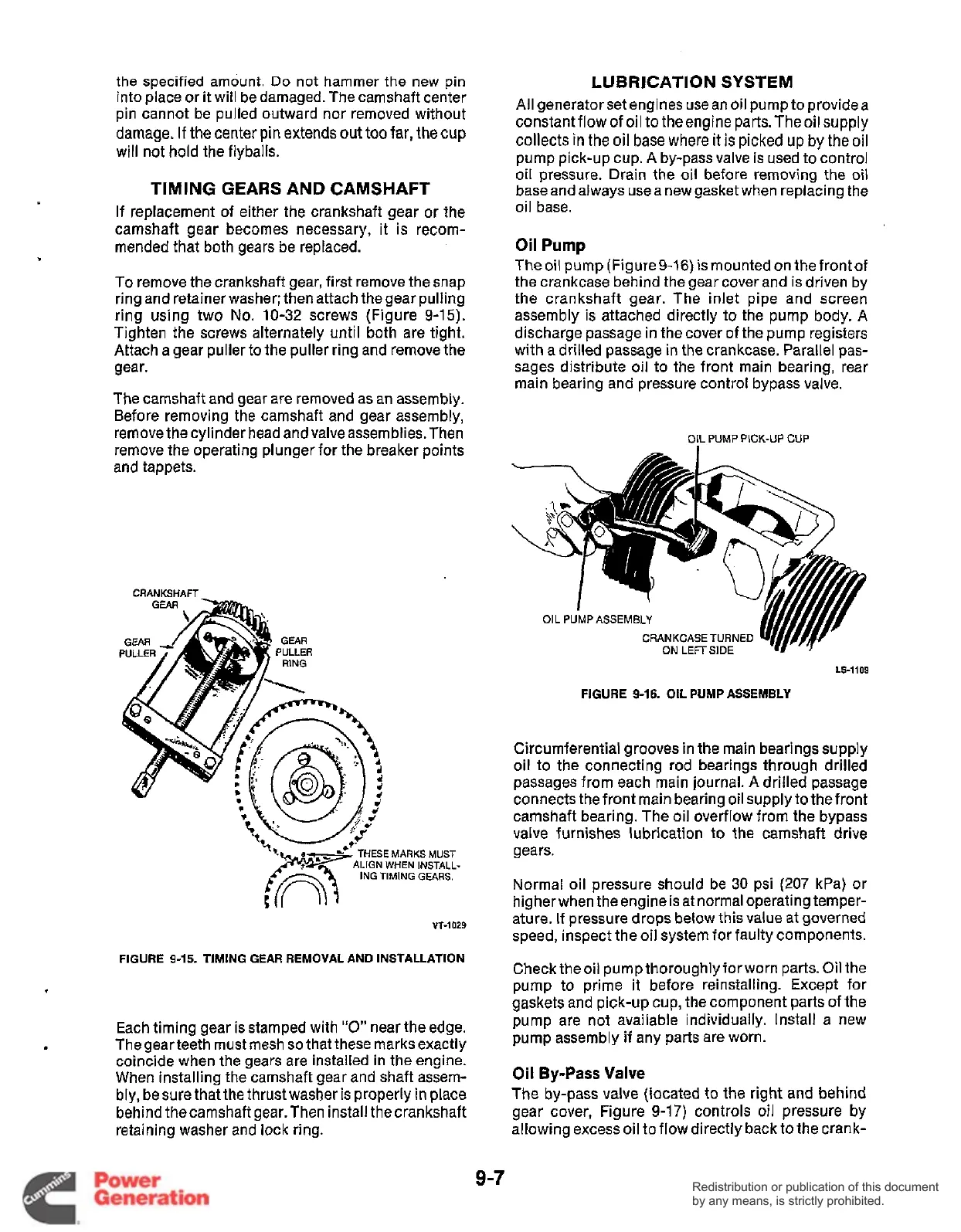

To remove the crankshaft gear, first remove the snap

ring and retainer washer; then attach the gear pulling

ring using two

No.

10-32

screws (Figure

9-15).

Tighten the screws alternately until both are tight.

Attach a gear puller to the puller ring and remove the

gear.

The camshaft and gear are removed

as

an assembly.

Before removing the camshaft and gear assembly,

remove the cylinder head and valve assemblies. Then

remove the operating plunger for the breaker points

and tappets.

CRANKSHAFT

THESE

MARKS

MUST

ALIGN

WHEN

INSTALL-

ING

TIMING

GEARS.

VT-1029

FIGURE 9-15.

TIMING

GEAR

REMOVAL

AND

INSTALLATION

.

Each timing gear is stamped with

“0”

near the edge.

The gearteeth must mesh

so

that these marks exactly

coincide when the gears are installed in the engine.

When installing the camshaft gear and shaft assem-

bly, be sure that the thrust washer

is

properly

in

place

behind thecamshaft gear.Then install thecrankshaft

retaining washer and lock ring.

LUBRICATION SYSTEM

All generator set engines use an oil pump to provide a

constant flow of oil to theengine parts.Theoil supply

collects

in

the

oil

base where

it

is

picked up by the oil

pump pick-up cup.

A

by-pass valve is used to control

oil pressure. Drain the

oil

before removing the oil

base and always usea new gasket when replacing the

oil base.

Oil

Pump

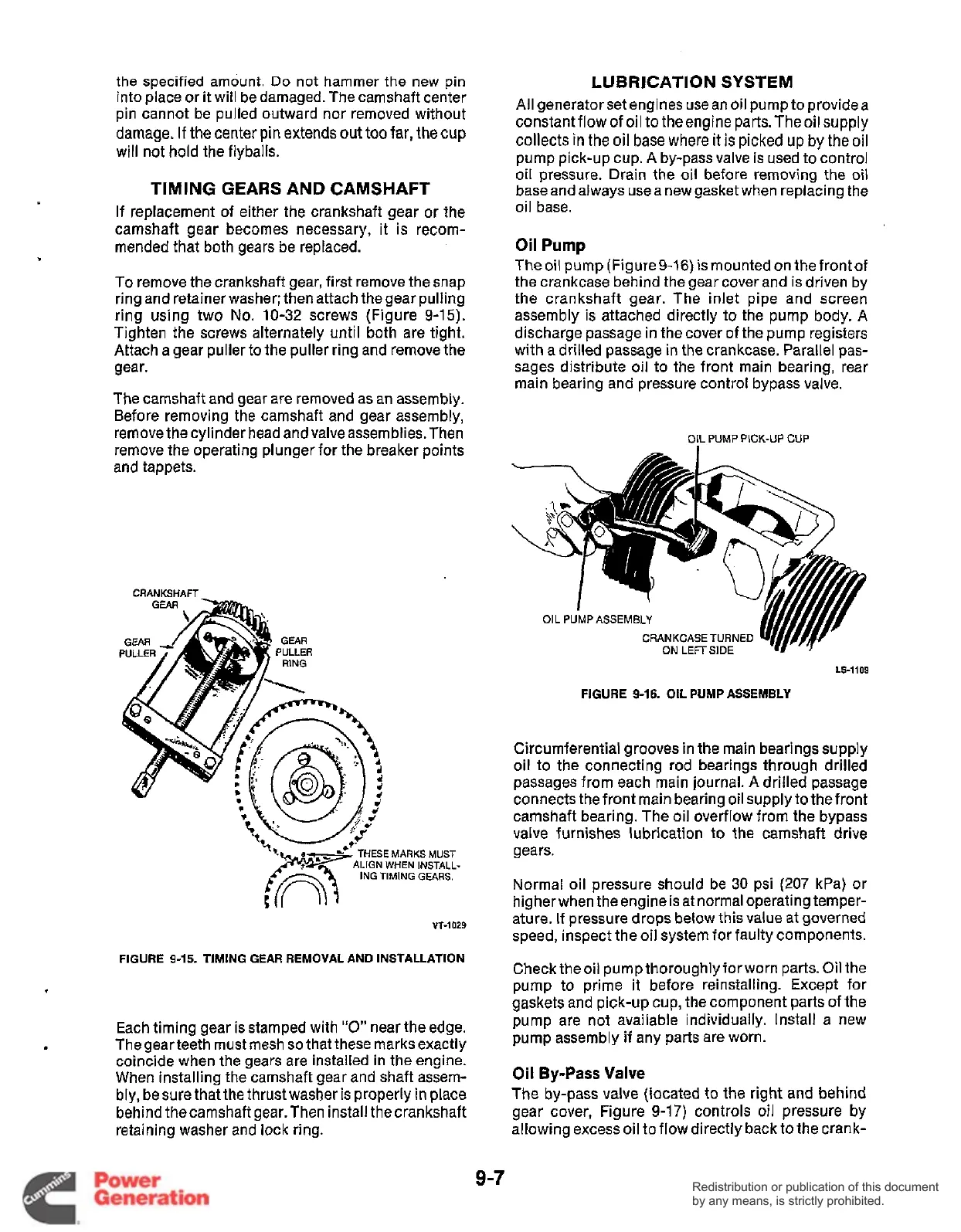

Theoil pump (Figure9-16) ismounted on the frontof

the crankcase behind the gear cover and is driven by

the crankshaft gear. The inlet pipe and screen

assembly is attached directly to the pump body. A

discharge passage in the cover of the pump registers

with a drilled passage in the crankcase. Parallel pas-

sages distribute oil to the front main bearing, rear

main bearing and pressure control bypass valve.

OIL

PUMP

PICK-UP

CUP

CRANKCASE

TURNED

ON

LEFT

SIDE

LS-1109

FIGURE

9-16.

OIL

PUMP

ASSEMBLY

Circumferential grooves in the main bearings supply

oil to the connecting rod bearings through drilled

passages from each main journal. A drilled passage

connects the front main bearing oil supply to the front

camshaft bearing. The oil overflow from the bypass

valve furnishes lubrication to the camshaft drive

gears.

Normal oil pressure should be

30

psi

(207

kPa) or

higher when the engine is at normal operating temper-

ature. If pressure drops below this value at governed

speed, inspect the oil system for faulty components.

Check theoil pump thoroughlyforworn parts.

Oil

the

pump to prime it before reinstalling. Except for

gaskets and pick-up cup, the component parts of the

pump are not available individually. Install a new

pump assembly if any parts are worn.

Oil

By-Pass

Valve

The by-pass valve (located to the right and behind

gear cover, Figure

9-17)

controls

oil

pressure by

allowing excess oil to flow directly back to the crank-

9-7

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

Loading...

Loading...