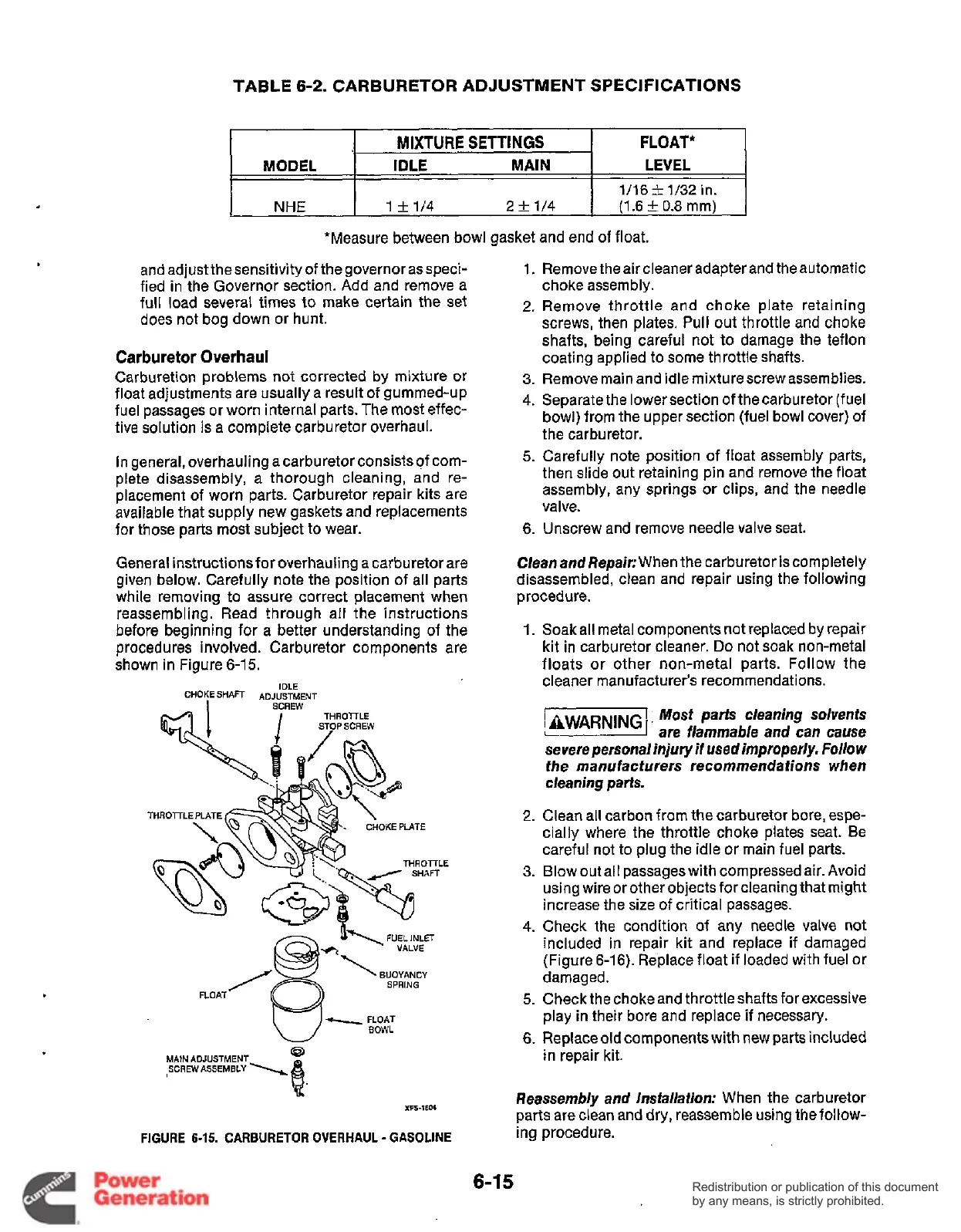

TABLE

6-2.

CARBURETOR ADJUSTMENT SPECIFICATIONS

MODEL

NHE

MIXTURE

SETTINGS

FLOAT*

IDLE

MAIN

LEVEL

1/16

t

1/32

in.

1

f1/4

2

f

1/4

(1.6

f

0.8

mm)

and adjust the sensitivity

of

the governor as speci-

fied in the Governor section. Add and remove a

full load several times to make certain the set

does not bog down

or

hunt.

Carburetor

Overhaul

Carburetion problems not corrected by mixture

or

float adjustments are usually a result of gummed-up

fuel passages

or

worn internal parts. The most effec-

tive solution is a complete carburetor overhaul.

In general, overhauling acarburetor consists of com-

plete disassembly, a thorough cleaning, and re-

placement of worn parts. Carburetor repair kits are

available that supply new gaskets and replacements

for those parts most subject to wear.

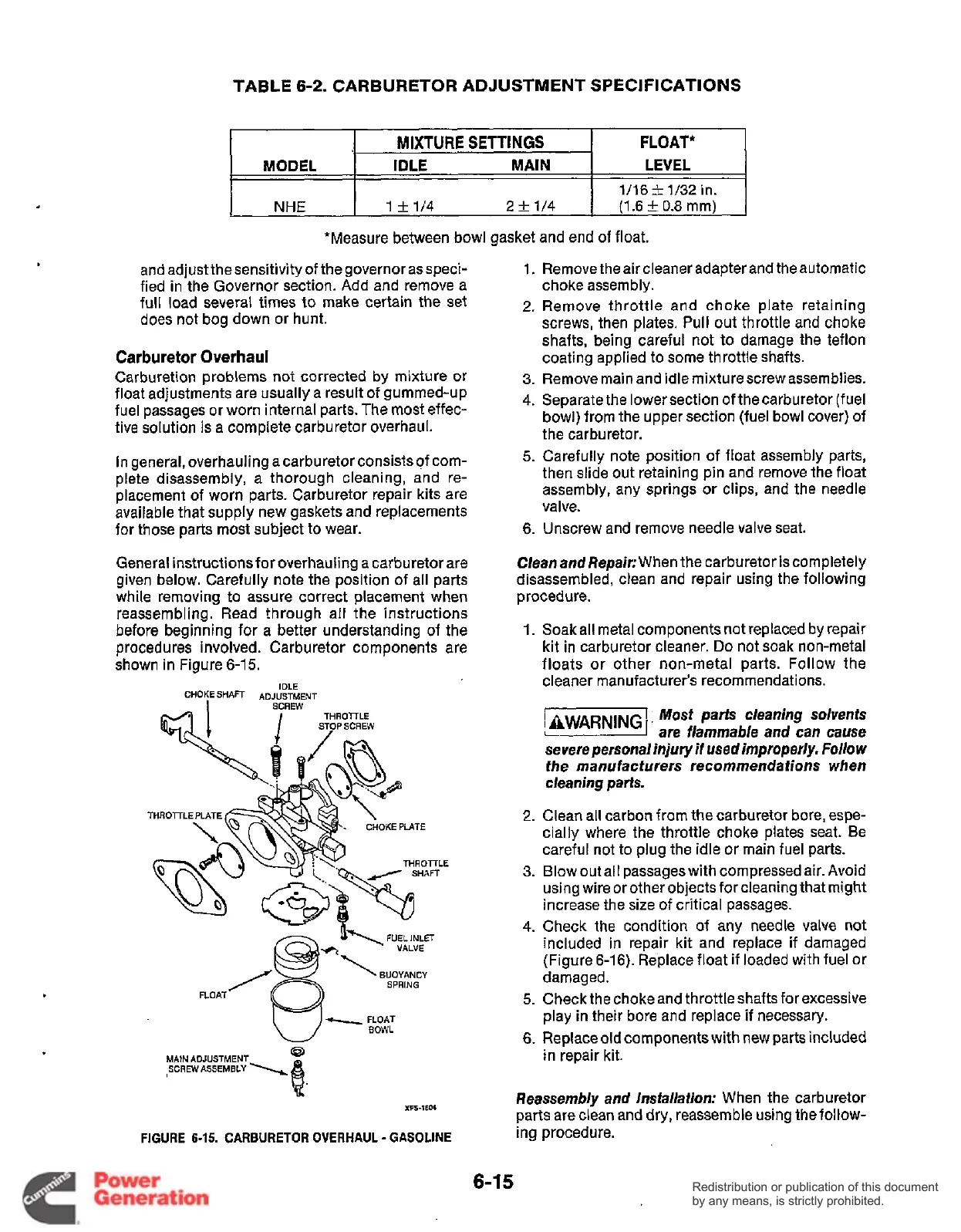

General instructionsfor overhauling a carburetor are

given below. Carefully note the position of all parts

while removing to assure correct placement when

reassembling. Read through all the instructions

before beginning

for

a better understanding of the

procedures involved. Carburetor components are

shown in Figure

6-15.

IDLE

CHOKESHAFT ADJUSTMENT

I

SCREW

FLOA1

SPRING

@

MAIN ADJUSTMENT

SCREW

ASSEMBLY

\

XFS-1604

FIGURE

6-15.

CARBURETOR

OVERHAUL

-

GASOLINE

1.

Remove the air cleaner adapter and the automatic

choke assembly.

2.

Remove throttle and choke plate retaining

screws, then plates. Pull out throttle and choke

shafts, being careful not to damage the teflon

coating applied to some throttle shafts.

3.

Remove main and idle mixturescrew assemblies.

4.

Separate the lower section of thecarburetor (fuel

bowl) from the upper section (fuel bowl cover) of

the carburetor.

5.

Carefully note position of float assembly parts,

then slide out retaining pin and remove the float

assembly, any springs

or

clips, and the needle

valve.

6.

Unscrew and remove needle valve seat.

Clean and Repair;

When the carburetor is completely

disassembled, clean and repair using the following

procedure.

1.

Soak all metal components not replaced by repair

kit in carburetor cleaner.

Do

not soak non-metal

floats

or

other non-metal parts. Follow the

cleaner manufacturer’s recommendations.

-1’:

Most parts cleaning solvents

severe personal injury

if

used improperly. Follow

the manufacturers recommendations when

cleaning parts.

2.

Clean all carbon from the carburetor bore, espe-

cially where the throttle choke plates seat. Be

careful not to plug the idle or main fuel parts.

3.

Blow out all passages with compressed air. Avoid

using wire

or

other objects

for

cleaning that might

increase the size of critical passages.

4.

Check the condition of any needle valve not

included in repair kit and replace if damaged

(Figure

6-16).

Replace float if loaded with fuel

or

damaged.

5.

Check the choke and throttle shafts for excessive

play in their bore and replace if necessary.

6.

Replace old components with new parts included

in repair kit.

1

I

are flammable and can cause

Reassembly and Installation:

When the carburetor

parts are clean and dry, reassemble using thefollow-

ing procedure.

6-1 5

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

Loading...

Loading...