CRANKSHAFT

To remove the crankshaft, loosen the rear bearing

plate screws and remove the bearing plate, gasket,

thrust washer, and shims. Turn the crankshaft

so

the

crankthrow is aligned with the notch in the rear open-

ing of the crankcase. Carefully slide the crankshaft

out of the crankcase.

Inspection

Inspect the rod and main bearing journals. If they are

worn or scored and cannot be smoothed out by pol-

ishing, either the journals should be reground to use

one of the standard undersize bearings or the crank-

shaft should be replaced. Remove only as much

metal as is required to restore the journal surface

while maintaining the recommended bearing clear-

ance.

Whenever making major repairs on the engine,

always inspect the drilled passages of the crankshaft.

Clean them

to

remove any foreign material and to

assure proper lubrication

of

the connecting rods.

Installation

Lubricate the front and rear main bearings with

engine oil. Use oil or gear lubricant to hold the front

thrust washer in place against the engine block. The

flat side of the thrust washer goes against the block.

Position the crankshaft

so

the crank throw is aligned

with the notch at the rear of the crankcase and install

the crankshaft. Make sure the front thrust washer did

not slip out

of

place during installation.

Place the oil seal loader

on

the oil seal guide and

driver and insert into the rear bearing plate. Remove

the seal guide and driver leaving the loader

in

the

bearing plate. The loader prevents the seal from

being cut on the crankshaft keyway during installa-

tion of the rear bearing plate.

Use oil or gear lubricant to hold the shim(s) and rear

thrust washer in position on the rear bearing plate

(see Figure

9-32).

The shim goes against the bearing

plate and the flat surface of the thrust washer goes

against the shim.

Place the bearing plate gasket

in

position on the

block, making sure the oil hole on the back of the

block is exposed. Install the rear bearing plate and

fasten with two nuts (or capscrews) tightened to the

specified torque. Make sure the rear thrust washer

and shim(s) did not slip out of place during installa-

tion. The crankshaft should turn freely by hand.

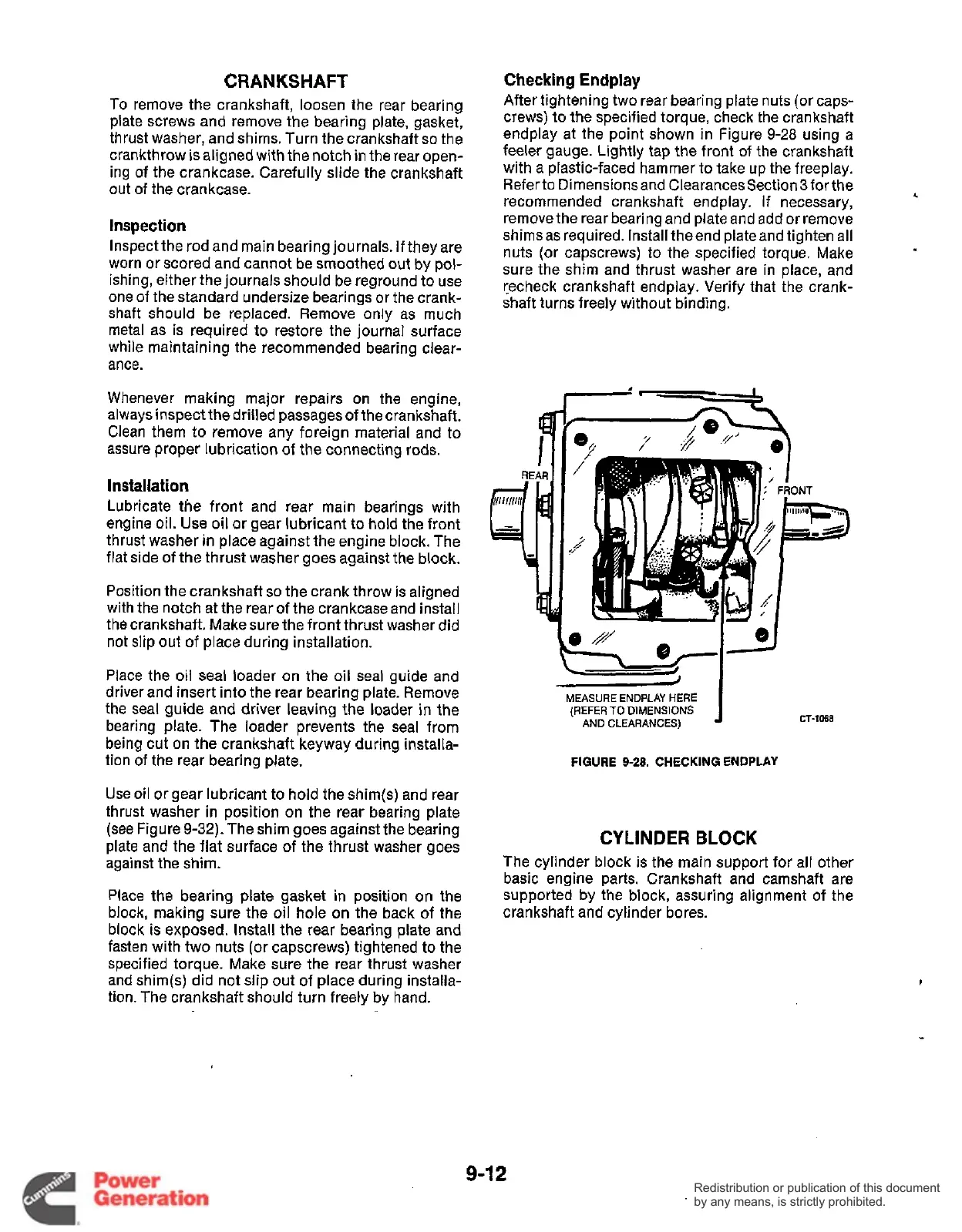

Checking

Endplay

After tightening two rear bearing plate nuts (or caps-

crews) to the specified torque, check the crankshaft

endplay at the point shown in Figure

9-28

using a

feeler gauge. Lightly tap the front of the crankshaft

with a plastic-faced hammer to take up the freeplay.

Refer to Dimensions and Clearances Section 3for the

recommended crankshaft endplay. If necessary,

remove the rear bearing and plate and add or remove

shimsas required. Install theend plateand tighten all

nuts (or capscrews) to the specified torque. Make

sure the shim and thrust washer are in place, and

recheck crankshaft endplay. Verify that the crank-

shaft turns freely without binding.

CT-1068

MEASURE

ENDPLAY

HERE

(REFER

TO

DIMENSIONS

AND

CLEARANCES)

FIGURE

9-28.

CHECKING

ENDPLAY

CYLINDER

BLOCK

The cylinder block is the main support for all other

basic engine parts. Crankshaft and camshaft are

supported

by

the block, assuring alignment of the

crankshaft and cylinder bores.

9-1

2

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

Loading...

Loading...