Section

9

-

Engine

Block

Assembly

GENERAL

The engine block assembly includes the pistons and

connecting rods, crankshaft, camshaft, valves and

lif-

ters, cylinder heads, lubrication system, timing gears,

governor mechanism, bearings, and cylinder block.

Performing any major service on the block assembly

will require that thegeneratorset be removed from the

coach (see Set Removal in Section

5).

In addition, to

gain complete access to the block assembly, the con-

trol, generator, and all primary engine systems must

also be removed. Refer to the previous sectionsforthe

disassembly and removal procedures.

OIL

FILTER

AND

ADAPTER

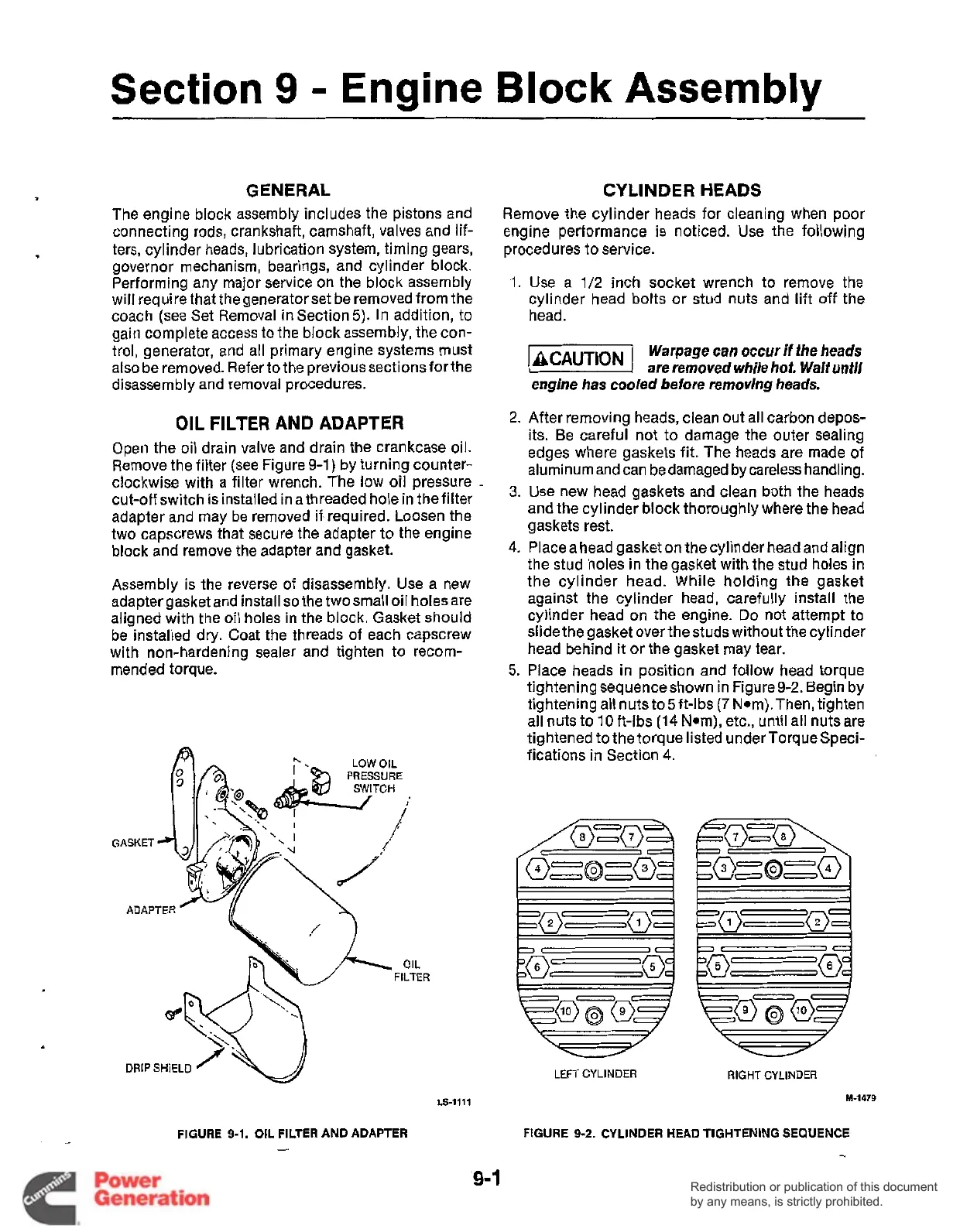

Open the oil drain valve and drain the crankcase oil.

Remove the filter (see Figure

9-1)

by turning counter-

clockwise with a filter wrench. The low oil pressure

cut-off switch is installed in athreaded hole in the filter

adapter and may be removed if. required. Loosen the

two capscrews that secure the adapter to the engine

block and remove the adapter and gasket.

Assembly is the reverse of disassembly. Use a new

adapter gasket and install

so

the two small oil holes are

aligned with the oil holes in the block. Gasket should

be installed dry. Coat the threads of each capscrew

with non-hardening sealer and tighten to recom-

mended torque.

LOW

OIL

h

LS-1111

FIGURE

9-1.

OIL

FILTER AND ADAPTER

-

CYLINDER HEADS

Remove the cylinder heads for cleaning when poor

engine performance is noticed. Use the following

procedures

to

service.

1. Use a

1/2

inch socket wrench to remove the

cylinder head bolts or stud nuts and lift off the

head.

2.

3.

4.

5.

Warpage can occur if

the

heads

ACAUTION

are removed while hot. Waif until

engine has cooled before removing heads.

After removing heads, clean out all carbon depos-

its. Be careful not

to

damage the outer sealing

edges where gaskets fit. The heads are made of

aluminum and can bedarnaged by careless handling.

Use new head gaskets and clean both the heads

and the cylinder block thoroughly where the head

gaskets rest.

Place a head gasket on the cylinder head and align

the stud holes in the gasket with the stud holes in

the cylinder head. While holding the gasket

against the cylinder head, carefully install the

cylinder head on the engine.

Do

not attempt to

slide the gasket over the studs without the cylinder

head behind

it

or the gasket may tear.

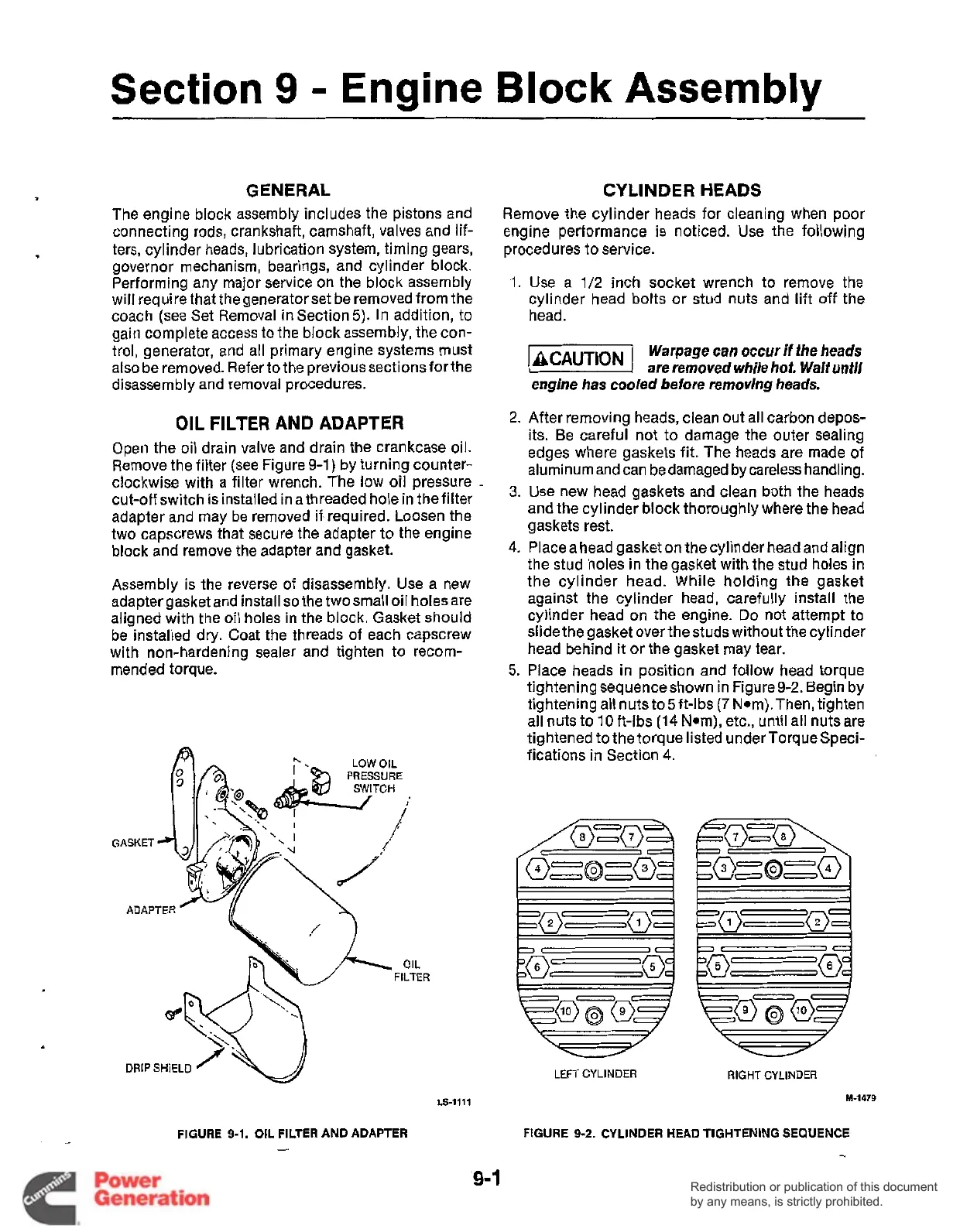

Place heads in position and follow head torque

tightening sequenceshown in Figure

9-2.

Begin by

tightening all nuts to5ft-lbs

(7

N*m).Then, tighten

all nuts to 10 ft-lbs (14 Nom), etc., until all nuts are

tightened to the torque listed under TorqueSpeci-

fications in Section 4.

LEFTCYLINDER

RIGHT

CYLINDER

M-1479

FIGURE

9-2.

CYLINDER HEAD TIGHTENING SEQUENCE

-

'9-1

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

Loading...

Loading...