Refer to Table 6-3 to determine the number of

degrees element cover must be rotated (clock-

wise) from reference position. Marks on choke

housing are spaced at

5"

intervals.

Rotate element cover asspecified and then tighten

cover mounting screws.

Move choke lever back and forth to check for

smooth operation. Lever should return automati-

cally to the free position when released from the

open position without sticking or binding.

Install plastic choke cover and tighten center

mounting nut.

ChokeReplacement:

If

the choke fails to open, remove

the protective plastic cover and check to see

if

the

heating element is working. The heating element cover

should become hot after a few minutes of operation. If

the element cover does not get hot, start the set and

then use an AC voltmeter to check for voltage (approx-

imately 20 VAC) at the element cover terminals.

If

voltage is not present, check for opens or shorts in the

control wiring.

If

the voltage is present at the heating element cover

terminals, stop the set and remove the heating element

cover. Inspect the heating element and replace

if

burned out or broken.

Also

inspect the bi-metal spiral

strip and replace if damaged, deteriorated, or dragging

in the housing.

When installing a new bi-metal strip, maintain the orig-

inal direction of spiral (see Figure 6-20). The outer tab

must point in a clockwise direction. Make sure the coil

sets squarely in the housing and the inner end of the

coil engages the slot in the choke shaft. When instal-

ling the element cover, make sure the slotted tang on

the cover engages the bi-metal strip.

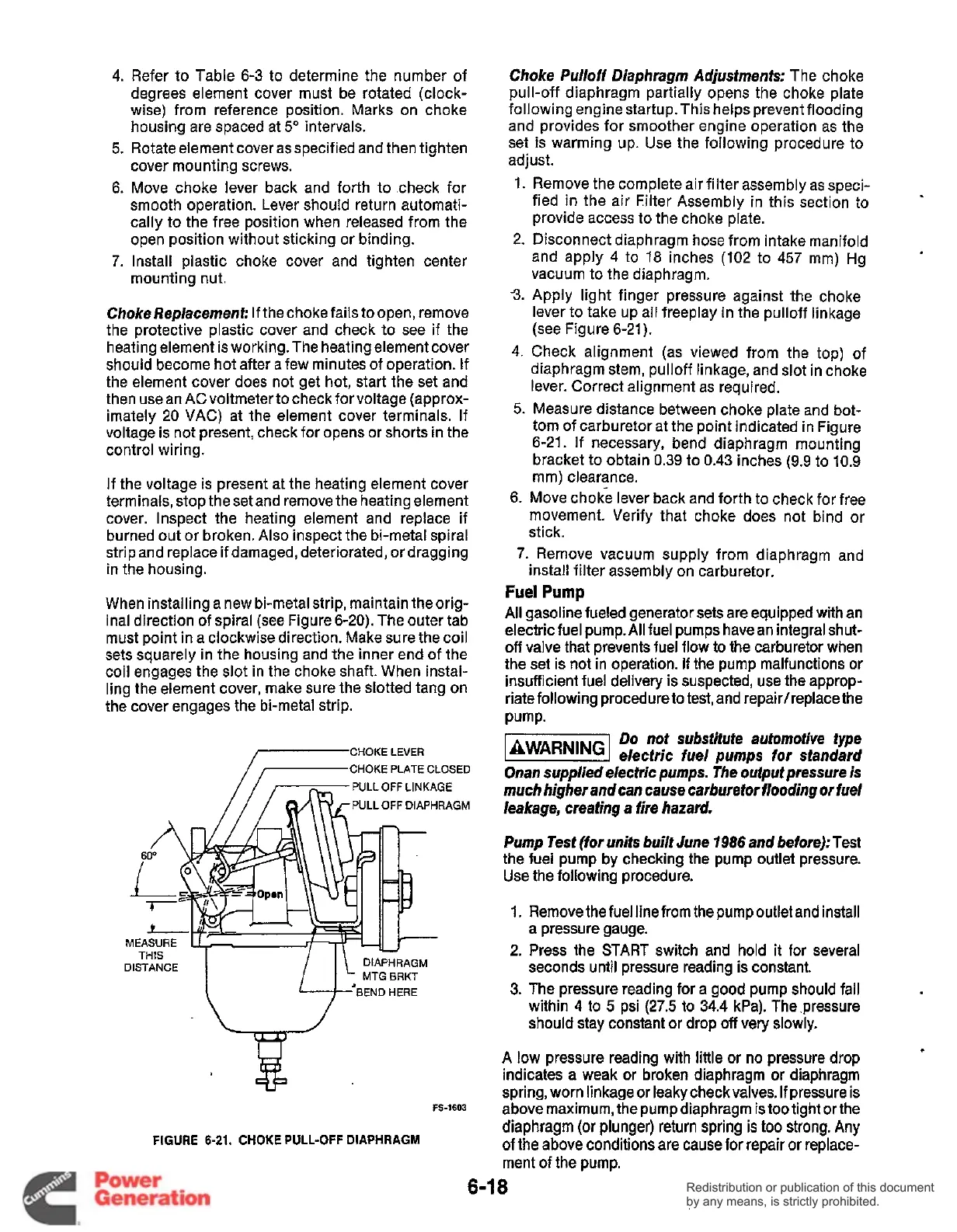

CHOKE LEVER

/-CHOKE

PLATE

CLOSED

.GM

L=J-

ENDHERE

FS-1603

FIGURE

6-21.

CHOKE

PULL-OFF DIAPHRAGM

Choke Pulloff Diaphragm Adjustments:

The choke

pull-off diaphragm partially opens the choke plate

following engine startup. This helps prevent flooding

and provides for smoother engine operation as the

set is warming up. Use the following procedure to

adjust.

1.

2.

3.

4.

Remove the complete air filter assembly as speci-

fied in the air Filter Assembly in this section to

provide access to the choke plate.

Disconnect diaphragm hose from intake manifold

and apply

4

to

18

inches (102 to 457 mm) Hg

vacuum to the diaphragm.

Apply light finger pressure against the choke

lever to take up all freeplay in the pulloff linkage

(see Figure 6-21).

Check alignment (as viewed from the top) of

diaphragm stem, pulloff linkage, and slot in choke

lever. Correct alignment as required.

5.

Measure distance between choke plate and bot-

tom of carburetor at the point indicated in Figure

6-21. If necessary, bend diaphragm mounting

bracket to obtain 0.39 to 0.43 inches (9.9 to 10.9

mm) clearance.

6. Move choke lever back and forth to check for free

movement. Verify that choke does not bind or

stick.

7.

Remove vacuum supply from diaphragm and

install filter assembly on carburetor.

Fuel

Pump

All

gasoline fueled generator sets are equipped with an

electric fuel pump.

All

fuel pumps have an integral shut-

off

valve that prevents fuel flow to the carburetor when

the set is not in operation.

If

the pump malfunctions or

insufficient fuel delivery is suspected, use the approp-

riate following procedure

to

test, and repairheplace the

Pump.

Do

not substitute automotive type

[BWARNINGI

electric fuel pumps for standard

Onan supplied electric pumps. The output pressure is

much higher and can cause carburetor flooding

or

fuel

leakage, creating a fire hazard.

Pump Test (for units built June

1986

and before):

Test

the fuel pump by checking the pump outlet pressure.

Use the following procedure.

1. Remove the fuel line from the pump outlet and install

a pressure gauge.

2.

Press the START switch and

hold it for several

seconds until pressure reading is constant.

3.

The pressure reading for a good pump should fall

within 4 to

5

psi

(27.5

to 34.4 kPa). The pressure

should stay constant or drop

off

very slowly.

A

low

pressure reading with little or no pressure drop

indicates a weak or broken diaphragm or diaphragm

spring, worn linkage or leakycheckvalves.

If

pressure is

above maximum, the pump diaphragm is too tight or the

diaphragm (or plunger) return spring

is

too

strong.

Any

of the above conditions are cause for repair or replace-

ment of the pump.

6-1

8

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

Loading...

Loading...