GENERATOR

SERVICE

This section covers generator disassembly and assem-

bly procedures. Referto Figures8-1 and8-2 tolocateand

identify the various generator components described in

each su b-section.

Generator

Disassembly

Use the following procedures to disassemble the

generator:

1. Drain the engine oil while the generator set is still

mounted in the vehicle.

2. Remove the generator set from the vehicle and place

it

on

a sturdy work bench. Refer to Set Removal in

Section

5

for the recommended set removal

procedures.

3.

Remove the flywheel guard (from scroll opening)

and the noise shield.

4.

The carburetor and intake manifold must be

removed to provide clearance for lifting the genera-

tor stator assembly. Disconect the choke heater lead

wires, throttle linkage, fuel line, crankcase breather

hose, and preheater tube. Remove the intake mani-

fold as an assembly. Refer to Fuel System in Section

6 for detailed removal procedures.

5.

Disconnect the lead wires from the charge resistor

(quick-disconnect type connections), the low oil

pressure cutoff switch, and the

B+

terminal on the

ignition coil.

6.

Remove the brush block cover and disconnect the

Bt

(outboard) and

B-

(inboard) lead wires from the

brush block terminals.

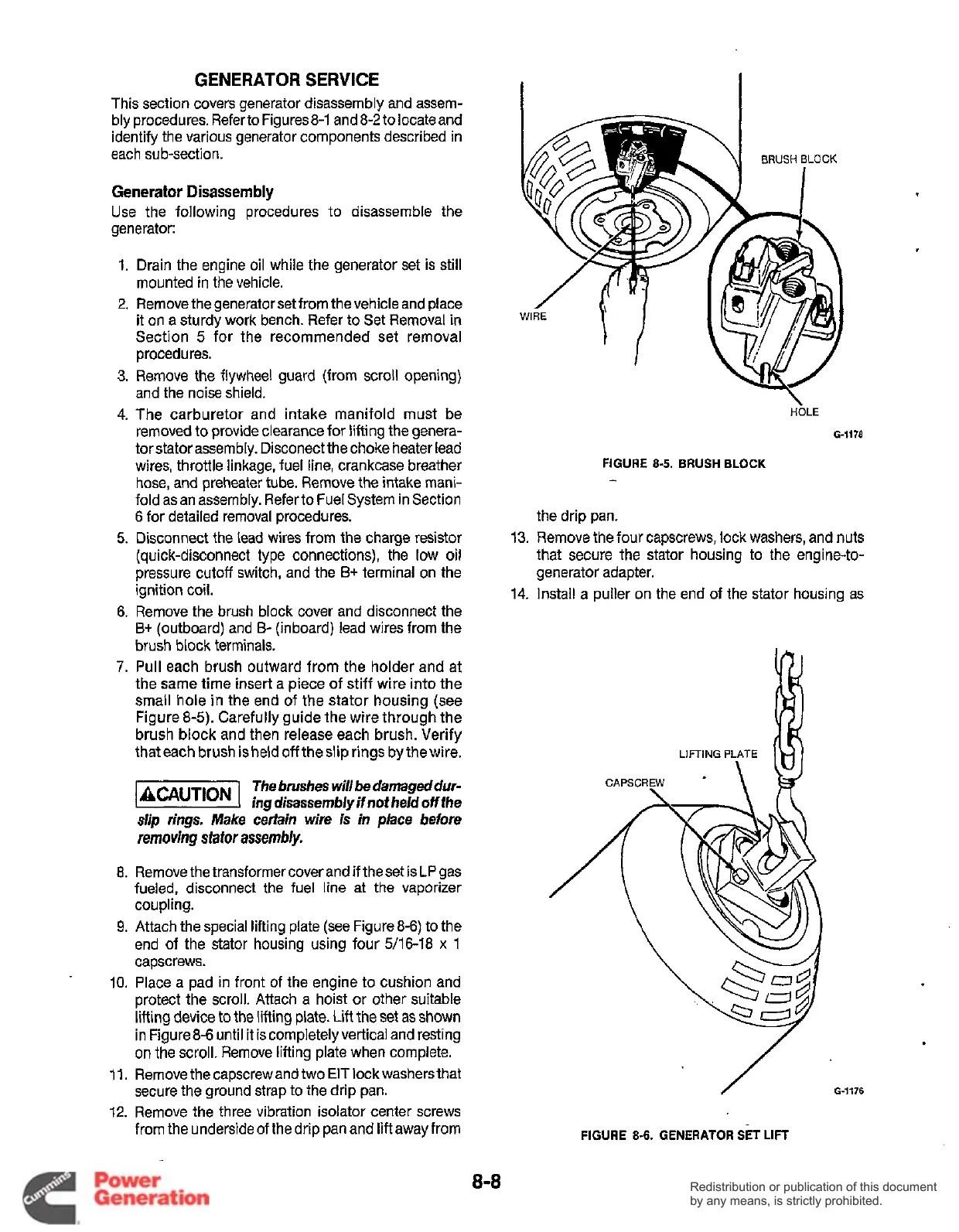

7.

Pull each brush outward from the holder and at

the same time insert a piece of stiff wire into the

small hole in the end

of

the stator housing (see

Figure 8-5). Carefully guide the wire through the

brush block and then release each brush. Verify

thateach brush is held

off

theslip rings by thewire.

BRUSH

BLOCK

HOLE

G-1178

FIGURE

8-5.

BRUSH

BLOCK

-

the drip pan.

13.

Remove the four capscrews, lock washers, and nuts

that secure the stator housing to the engine-to-

generator adapter.

14. Install a puller on the end of the stator housing as

The brushes will

be

damageddur-

incrdisassemblvif notheld offfhe

slip

rings.

Make

c&dn wire

is

in place before

removing

sfafor

assembly.

8.

Remove the transformer coverand

if

theset is

LP

gas

fueled, disconnect the fuel line at the vaporizer

coupling.

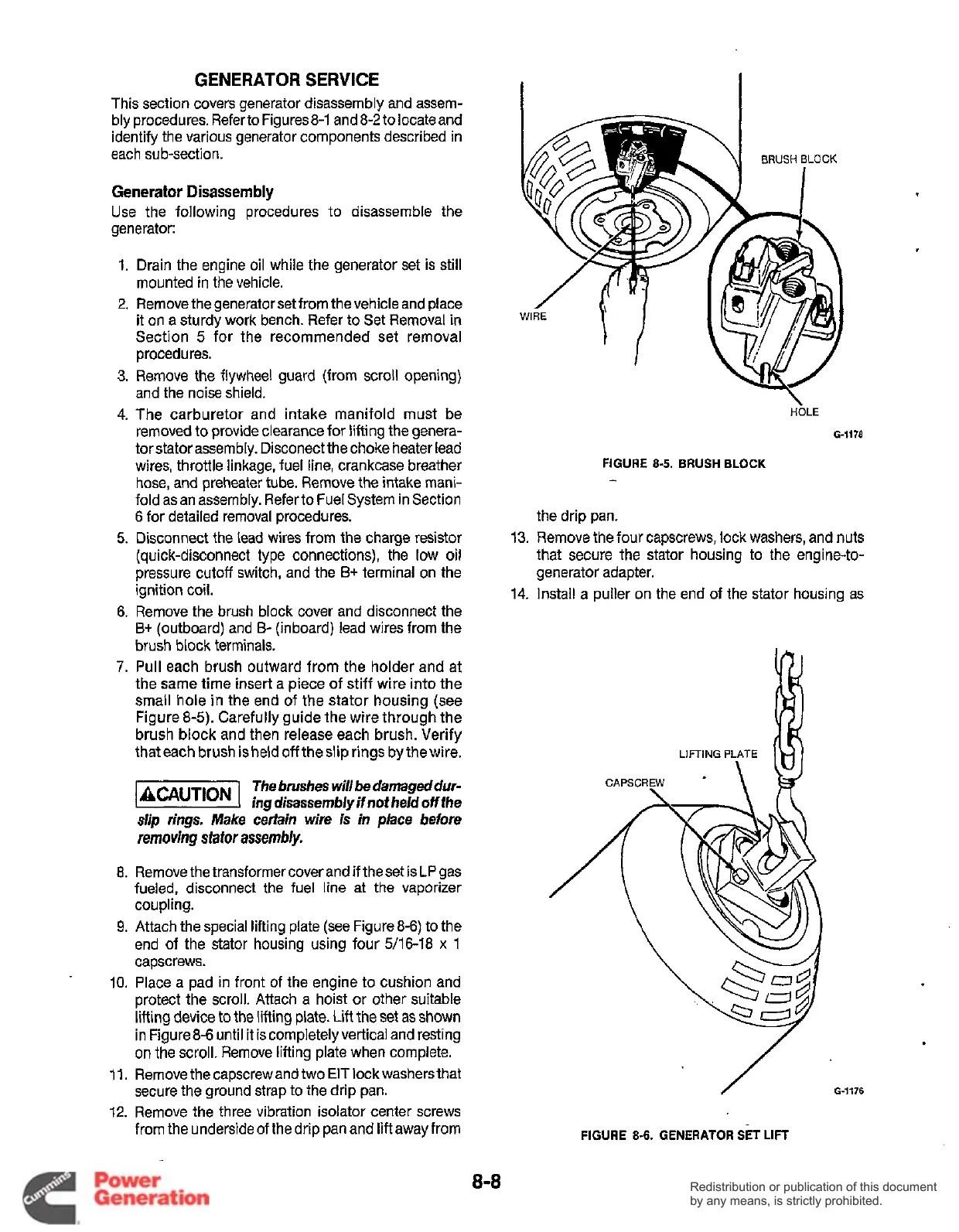

9.

Attach the special lifting plate (see Figure 8-6)

to

the

end of the stator housing using four 5/16-18

x

1

10.

11.

12.

capscrews.

Place a pad in front

of

the engine to cushion and

protect the scroll. Attach a hoist or other suitable

lifting device

to

the lifting plate.

Lift

the set as shown

in Figure84 until it is completelyvertical and resting

on the scroll. Remove lifting plate when complete.

Remove the capscrew and

two

EIT

lock washers that

secure the ground strap to the drip pan.

Remove the three vibration isolator center screws

from the underside of thedrip pan and liftawayfrom

8-8

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

Loading...

Loading...