is dissolved in the liquid propane and forms into gra-

nules as the fuel is vaporized. Remove regulator front

cover and diaphragm assembly (see Figure 6-29) to

check for dirt or oil deposits.

If

granules are

embedded in the Vitton rubber of the secondary

valve, wash the valve and seat clean.

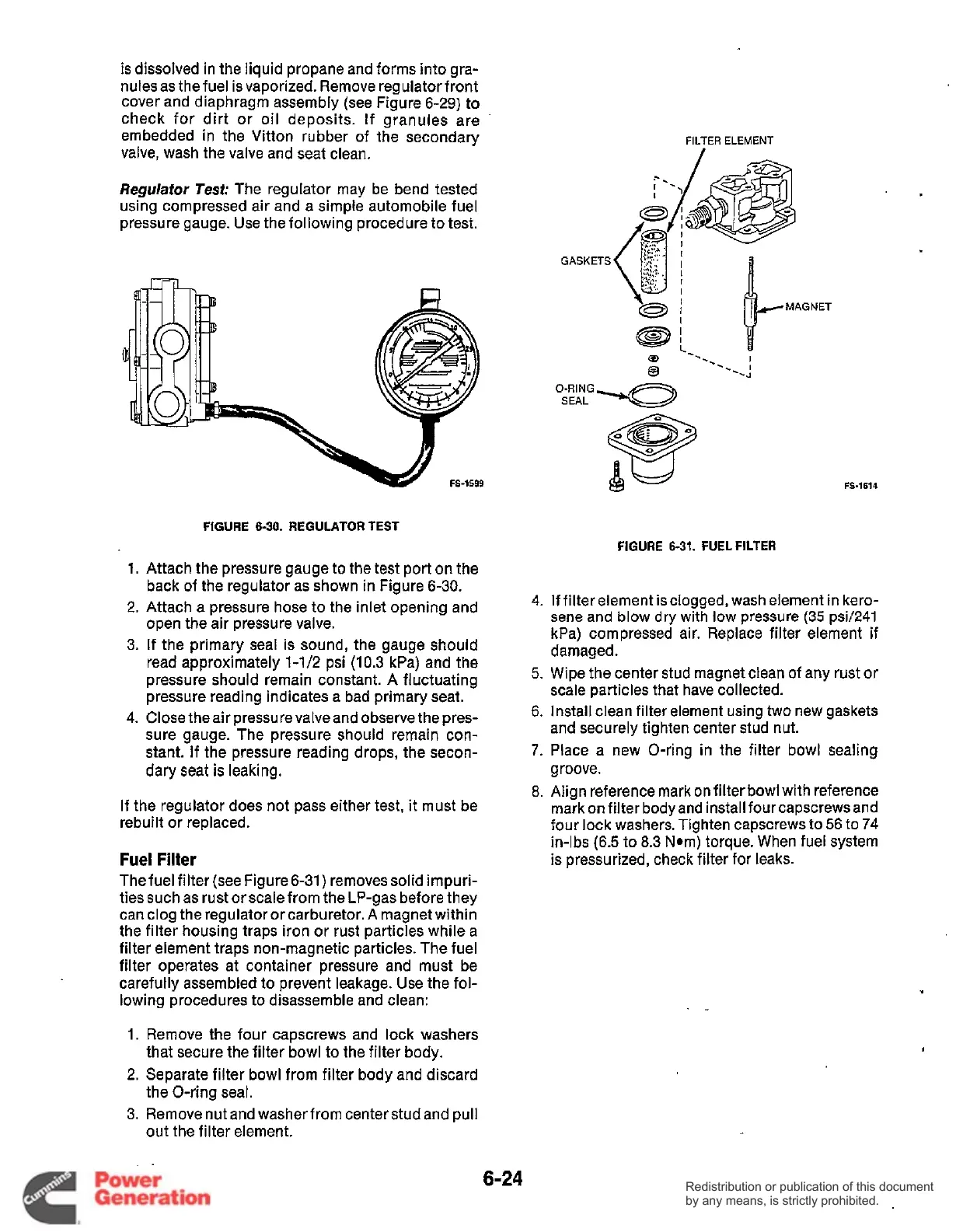

Regulafor

Test:

The regulator may be bend tested

using compressed air and a simple automobile fuel

pressure gauge. Use the following procedure to test.

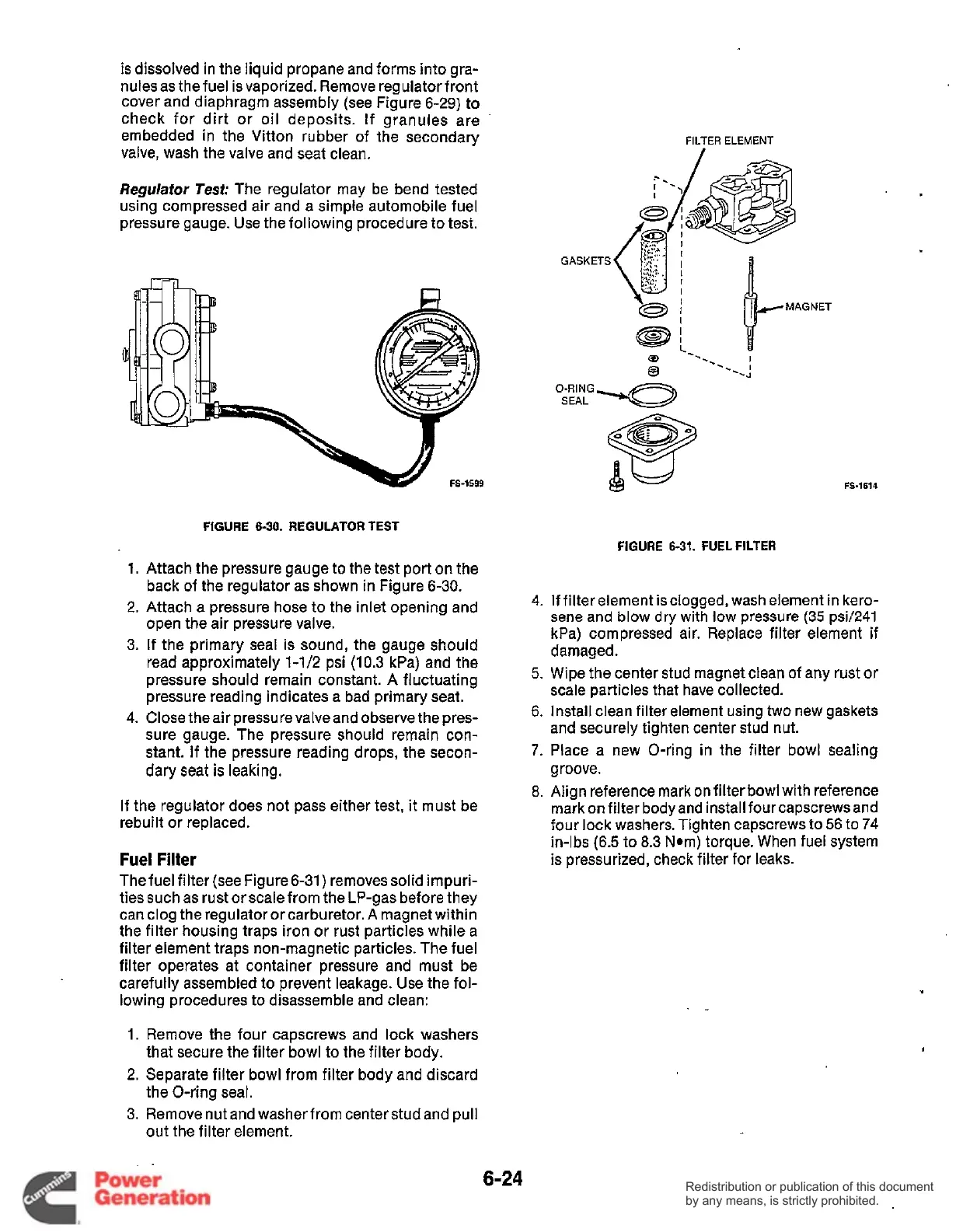

FILTER ELEMENT

GASKETS

FIGURE 6-30. REGULATOR TEST

FIGURE 6-31. FUEL FILTER

1. Attach the pressure gauge to the test port on the

back of the regulator as shown in Figure

6-30.

2. Attach a pressure hose to the inlet opening and

open the air pressure valve.

3.

If the primary seal is sound, the gauge should

read approximately 1-1/2 psi

(10.3

kPa) and the

pressure should remain constant.

A

fluctuating

pressure reading indicates a bad primary seat.

4. Close the air pressure valve and observe the pres-

sure gauge. The pressure should remain con-

stant. If the pressure reading drops, the secon-

dary

seat

is

leaking.

If the regulator does not pass either test,

it

must be

re bui

It

or replaced.

Fuel

Filter

The fuel filter (see Figure6-31) removes solid impuri-

tiessuch as rust orscale from the LP-gas before they

can clog the regulator orcarburetor.

A

magnet within

the filter housing traps iron

or

rust particles while a

filter element traps non-magnetic particles. The fuel

filter operates at container pressure and must be

carefully assembled to prevent leakage. Use the fol-

lowing procedures to disassemble and clean:

Remove the four capscrews and lock washers

that secure the filter bowl to the filter body.

Separate filter bowl from filter body and discard

the O-ring seal.

Remove nut and washer from center stud and pull

out the filter element.

FS-1614

4. If filter element is clogged, wash element in kero-

sene and blow dry with low pressure

(35

psi/241

kPa) compressed air. Replace filter element if

damaged.

5.

Wipe the center stud magnet clean

of

any rust

or

scale particles that have collected.

6.

Install clean filter element using two new gaskets

and securely tighten center stud nut.

7. Place a new O-ring in the filter bowl sealing

groove.

8.

Align reference mark on filter bowl with reference

mark on filter body and install four capscrewsand

four lock washers. Tighten capscrews to 56 to 74

in-lbs (6.5 to

8.3

Nom) torque. When fuel system

is pressurized, check filter for leaks.

6-24

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

Loading...

Loading...