SECTION 3 - HANDLING, STORAGE, AND INSTALLATIONPACE │ Installation & Assembly Manual

Issue Date: 07/03/2018

30

Form PA102.20-N1

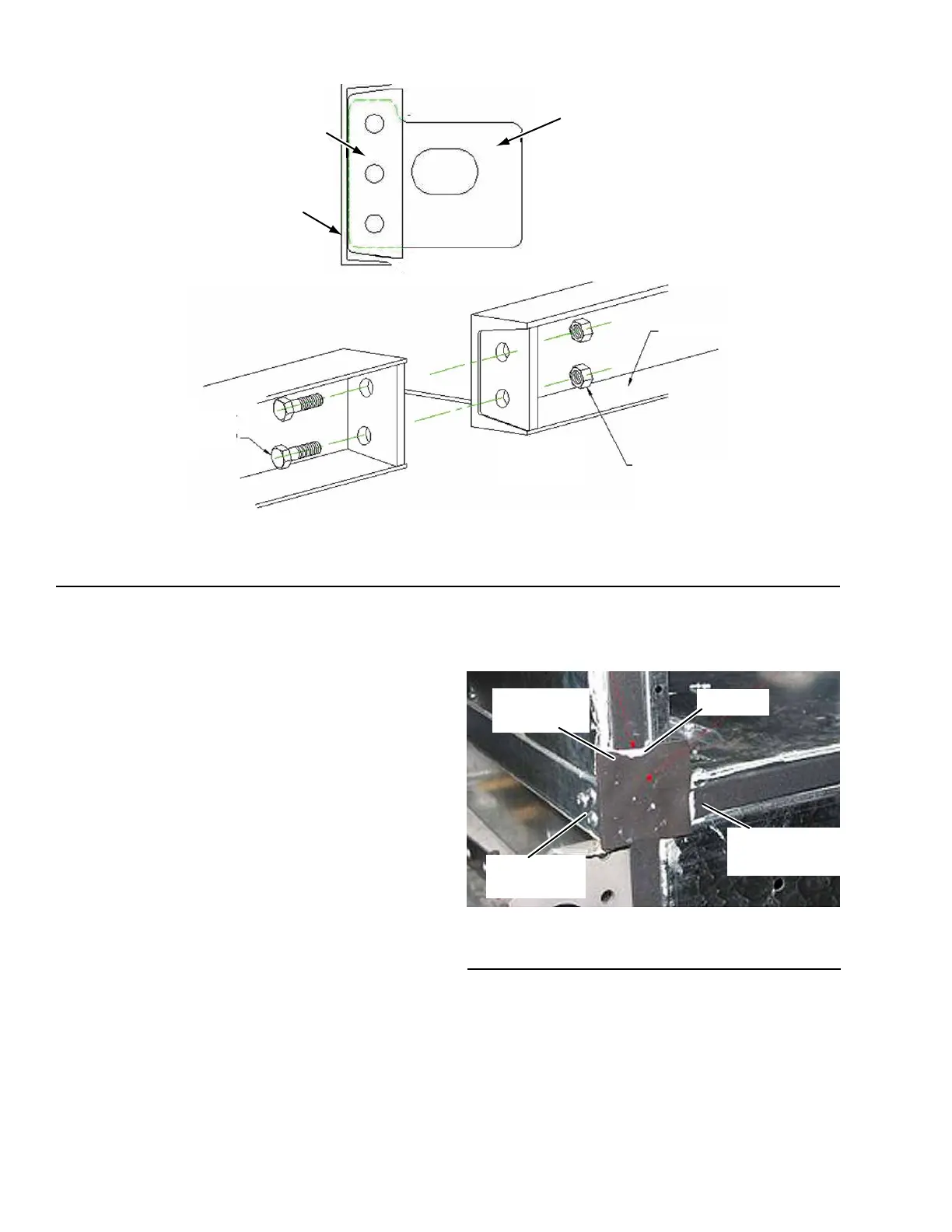

Figure 20 - Shipping Split Examples Using Structural Steel Baserails

LD14263

WELDED CHANNEL FILLER

BASE CHANNEL

REMOVABLE LIFTING LUGS

BASE CHANNEL

3/4 in ZINC HEX NUT

(Use from Lifting Lug)

(No Flat or Lock

Washers Required)

3/4 in GR5 HEX BOLT

(Use from Lifting Lug)

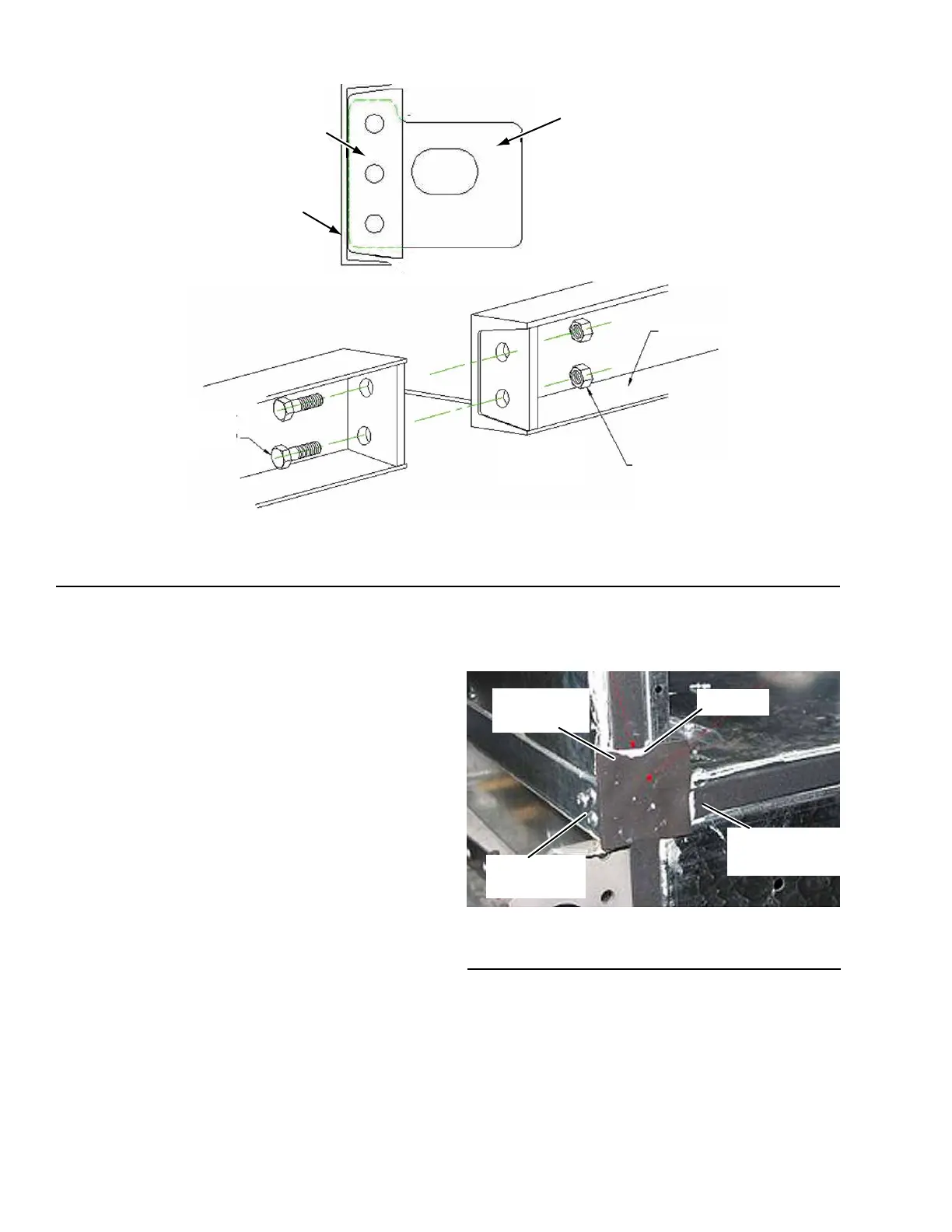

Figure 21 - Applying Gasket Square, Neoprene

Gasket and Caulk to Raceway Split

LD13372

NEOPRENE

GASKET

GASKET

SQUARE

RACEWAY

SPLIT

CAULK

9. Make sure all wiring and/or control tubing con-

nection pigtails are secured out of the path of the

shipping split mating surfaces to prevent damage.

10. Apply separate gasket squares (P/N 028-11883-

010) as shown in Figure 21 on page 30. Place

one square at each corner of the face of each sec-

tion.

11. Apply neoprene gasket (P/N 028-11883-010 or

P/N 028-11873-010) to face the perimeter from

square to square, and 1/4 in. from the outside

edge of the mating surface (nearest to AHU exte-

rior) to allow for a 1/4 in. bead of caulk. The gasket

application should provide a continuos seal from

side-to-side, and to the top of the AHU roof to the

bottom of the AHU base where it meets the curb.

12. Apply a 1/2 in. thick bead of caulk (not provided),

to the curb top surface only, where the rst section

will be placed.

Loading...

Loading...