SECTION 3 - HANDLING, STORAGE, AND INSTALLATIONPACE │ Installation & Assembly Manual

Issue Date: 07/03/2018

34

Form PA102.20-N1

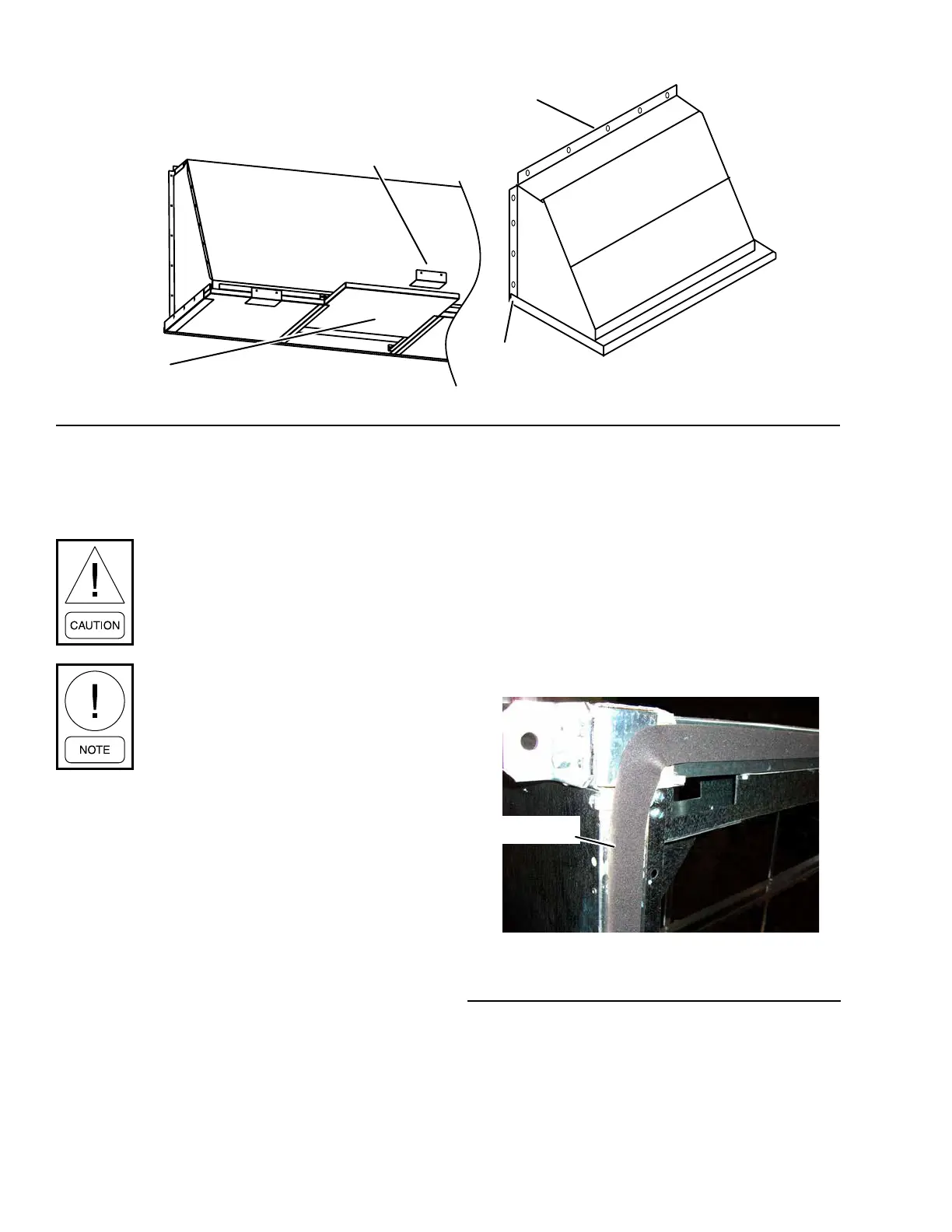

MOISTURE

ELIMINATOR

CLIP

BUTYL

TAPE

CAULK

LD13783

Figure 31 - Installing Hood with Optional Moisture Eliminators

5. Remove the plastic shipping covers and supports.

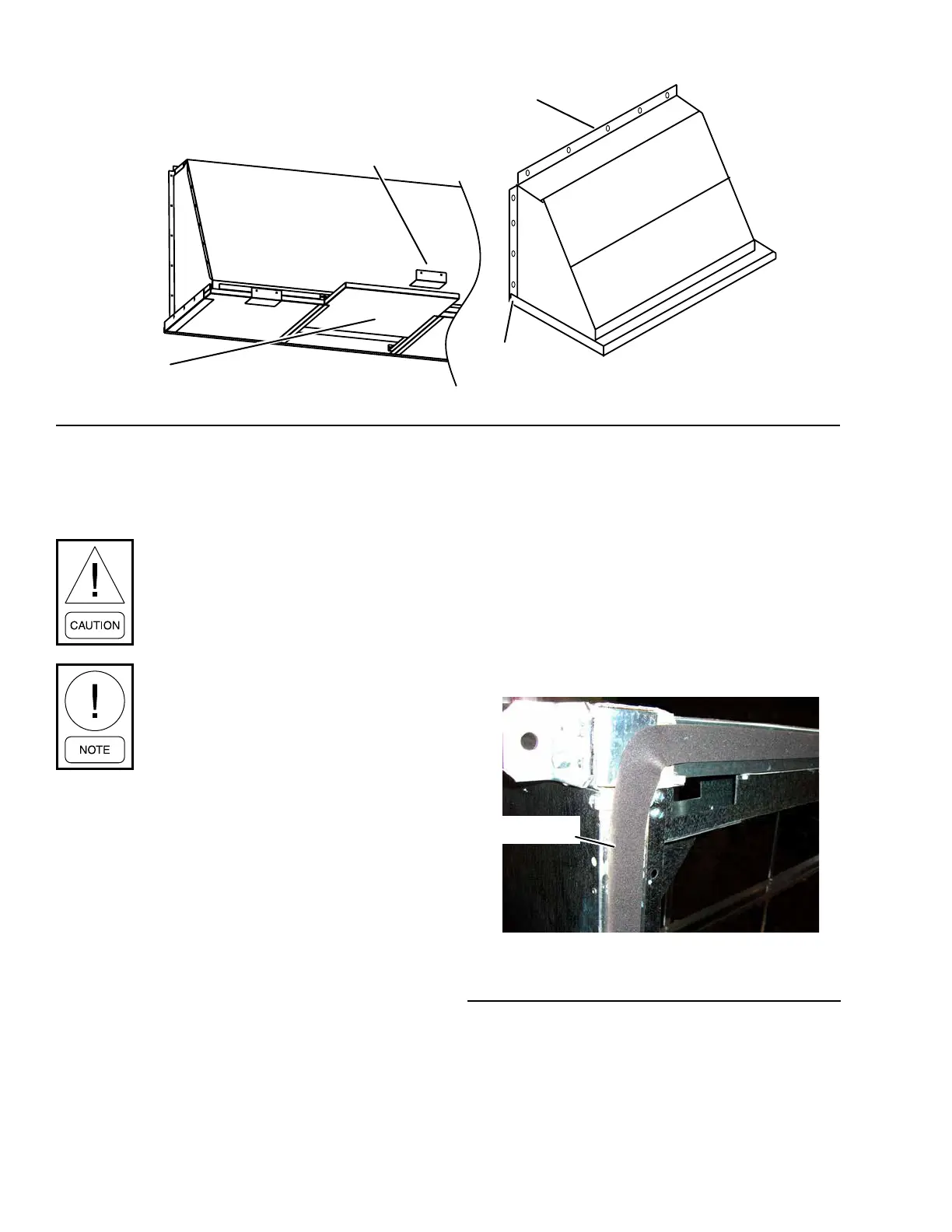

6. Apply neoprene gasket (P/N 028-15954-010) to

one side only of each shipping split as shown in

Figure 32 on page 34. If there is a door frame

at the shipping split, apply neoprene gasket (P/N

028-11873-010) as shown in Figure 33 on page

35. Make sure the entire perimeter is covered

with the gasket material, including the foamed

corners as shown in Figure 33 on page 35. Any

void, depression, or protrusion will allow air or wa-

ter leakage. Make any splices on a straight run.

LD13779

Figure 32 - Use Gasket (P/N 028-11883-010) at

Shipping Split

GASKET

INSTALLING INDOOR AHU

Before installing the indoor AHU, identify the shipped

loose parts such as gaskets as shown in Figure 52 on

page 43 through Figure 70 on page 46.

Do not damage factory installed pipe

chase, electrical cabinet, hoods, pipe

stubs, door handles or roof overhang

when installing AHU.

If the AHU or AHU sections are too

large to t through an opening, contact

the local PACE Field Service Ofce for

assistance. Technical instructions are

available for disassembly and reas-

sembly.

Before placing the skids together:

1. If applicable, remove the metal bracket attached

to the cross channel and wood shipping blocks

before assembling the shipping splits.

2. If AHU sections are going to be assembled before

placing them, be sure the sections are on a at

surface during assembly.

3. Verify the correct sections and orientation of each

section.

4. Remove the cross brace(s) (shipping supports)

from each section’s shipping split.

Loading...

Loading...