−

B35

−−

B34

−

English

6. Maintenance and Inspections

Maintenance and Inspections

• Routine maintenance and inspection of the driver and motor are essential for

the proper and safe operation.

Notes on Maintenance and Inspection

1)Turnonandturnoffshouldbedonebyoperatorsorinspectorsthemselves.

2)Internalcircuitofthedriveriskeptchargedwithhighvoltageforawhileevenafter

power-off.Turnoffthepowerandallow15minutesorlongerafterLEDdisplayof

thefrontpanelhasgoneoff,beforeperformingmaintenanceandinspection.

3)Disconnectalloftheconnectiontothedriverwhenperformingmeggertest(Insulation

resistancemeasurement)tothedriver,otherwiseitcouldresultinbreakdownofthe

driver.

4)Donotusebenzine, thinner, alcohol, acidic cleanerandalkaline cleaner because

theycandiscolorordamagetheexteriorcase.

Inspection Items and Cycles

Generalandnormalrunningcondition

Ambient conditions : 30 ˚C (annual average), load factor of 80 % or

lower, operating hours of 20 hours or less per day.

Performthedailyandperiodicalinspectionaspertheitemsbelow.

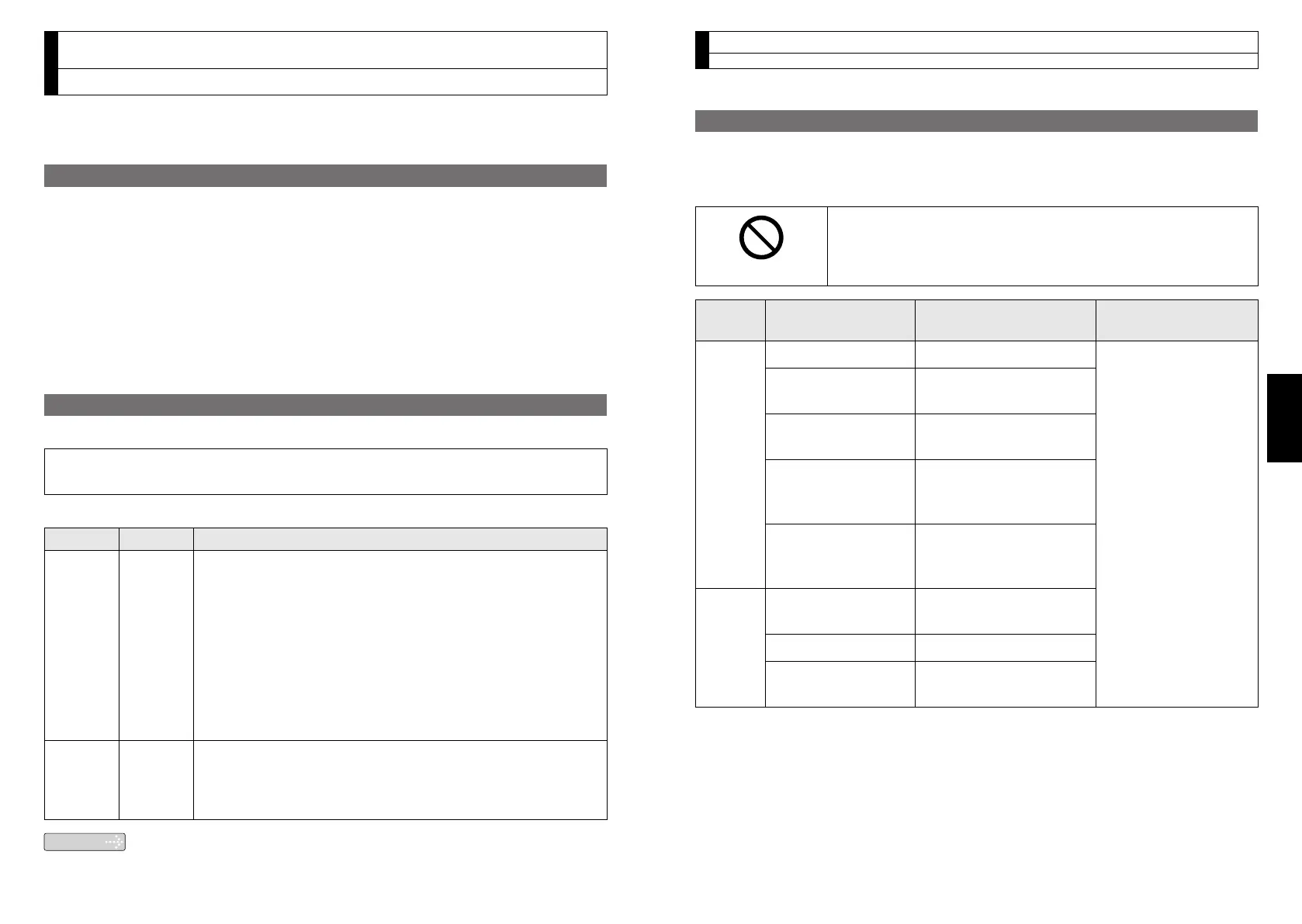

Type Cycles Items to be inspected

Daily

inspection

Daily

•Ambienttemperature,humidity,speck,dustorforeignobject

•Abnormalvibrationandnoise

•Maincircuitvoltage

•Odor

•Lintorotherparticlesatairholes

•Cleannessatfrontportionofthedriverandconnector

•Damageofthecables

•Looseconnectionormisalignmentbetweenthemotorand

machineorequipment

•Pinchingofforeignobjectattheload

Periodical

inspection

Annual

•Loosetightening

•Traceofoverheat

•Damagetotheterminalblock

•Loosefastenersonterminalblock

Note

Inspection cycle may change when the running conditions of the

above change.

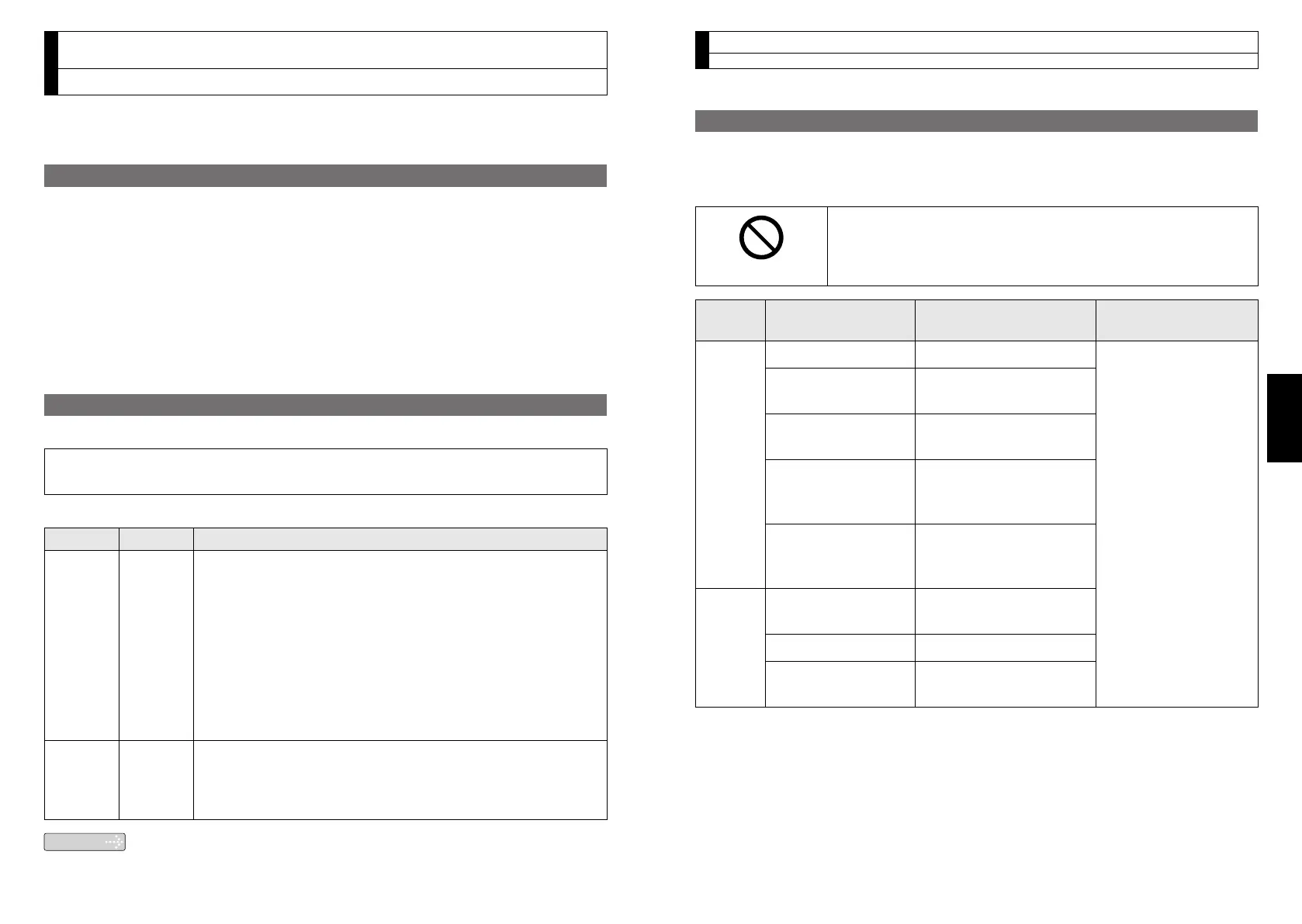

Guideline for Parts Replacement

Usethetablebelowforareference.Partsreplacementcyclevariesdependingonthe

actualoperatingconditions.Defectivepartsshouldbereplacedorrepairedwhenany

errorhaveoccurred.

Prohibited

Disassembling for inspection and repair should be

carried out only by authorized dealers or service

company.

Product Component

Standard replacement

cycles (hour)

Note

Driver

Smoothingcondenser Approx.5years

Thesehoursorcycles

arereference.

Whenyouexperience

anyerror,replacement

isrequiredevenbefore

thisstandardreplace-

mentcycle.

Coolingfan

2to3years

(10,000to30,000hours)

Aluminumelectrolytic

capacitor(onPCB)

Approx.5years

Rushcurrent

preventiverelay

Approx.100,000times

(dependingonworking

condition)

Rushcurrent

preventiveresistor

Approx.20,000times

(dependingonworking

condition)

Motor

Bearing

3to5years

(20,000to30,000hours)

Oilseal 5000hours

Encoder

3to5years

(20,000to30,000hours)

6. Maintenance and Inspections

Maintenance and Inspections

Loading...

Loading...