−

B5

−−

B4

−

English

2. Installation

Driver

Install the driver properly to avoid a breakdown or an accident.

Installation Place

1)

Installthe driverina controlpanel enclosedinnoncombustible materialand placedindoor

wheretheproductisnotsubjectedtorainordirectsunlight.Theproductsarenotwaterproof.

2)Wheretheproductsarenotsubjectedtocorrosiveatmospheressuchashydrogen

sulde,sulfurousacid,chlorine,ammonia,sulfur,chloricgas,sulfuricgas,acid,al-

kalineandsaltandsoon,andarefreefromsplashofinammablegas.

3)Wherethemotorisfreefromgrindingoil,oilmist,ironpowderorchips.

4)Well-ventilatedandlowhumidityanddust-freeplace.

5)Vibration-freeplace.

6)Donot usebenzine, thinner,alcohol, acidiccleaner andalkaline cleanerbecause

theycandiscolorordamagetheexteriorcase.

Environmental Conditions

Item Conditions

*

1Extremetempera-

turesarepermissible

onlyforshortpe-

riodsuchasduring

transportation.

*

2Air containing water

vaporwillbecome

saturatedwith water

vaporasthetemper-

ature falls,causing

dew.

Ambienttemperature 0˚Cto50˚C(freefromfreezing)

Ambienthumidity 20%to85%RH(freefromcondensation)

Storagetemperature

*

1

–20˚Cto65˚C(Max.temperatureguarantee:

80˚Cfor72hoursfreefromcondensation

*

2

)

Storagehumidity 20%to85%RH(freefromcondensation

*

2

)

Vibration Lowerthan5.88m/s

2

(0.6G),10to60Hz

Altitude Lowerthan1000m

How to Install

1)Rack-mounttype.Installinverticalposition,andreserveenoughspacearoundthe

servodriverforventilation.

2)Basemount(rearmount)isstandardforA/B/C/D-framedriver.

3)

TochangethemountingsurfaceofA/B/C/D-framedriver,usetheoptionalmountingxture.

Forchoosingthecorrectoptionalmountingxture,refertotheOperatingInstructions(Overall).

4)Forthedimensionsandmassoftheproduct,whicharenecessarydesigndataof

themountingsection,refertothedimensionaloutlinedrawingontheOperatingIn-

structions(Overall)ortheDeliverySpecication.

5)Inconsideration ofstrengthofthescrewsandthematerialofthemountingbase,

select appropriatefasteningtorquefortheproduct mounting screws, so that the

screwswillnotbeloosenedordamaged.

Example) Totightenasteelscrewintoasteelbase,AtoF-frame:M52.7to3.3N·m

2. Installation

Driver

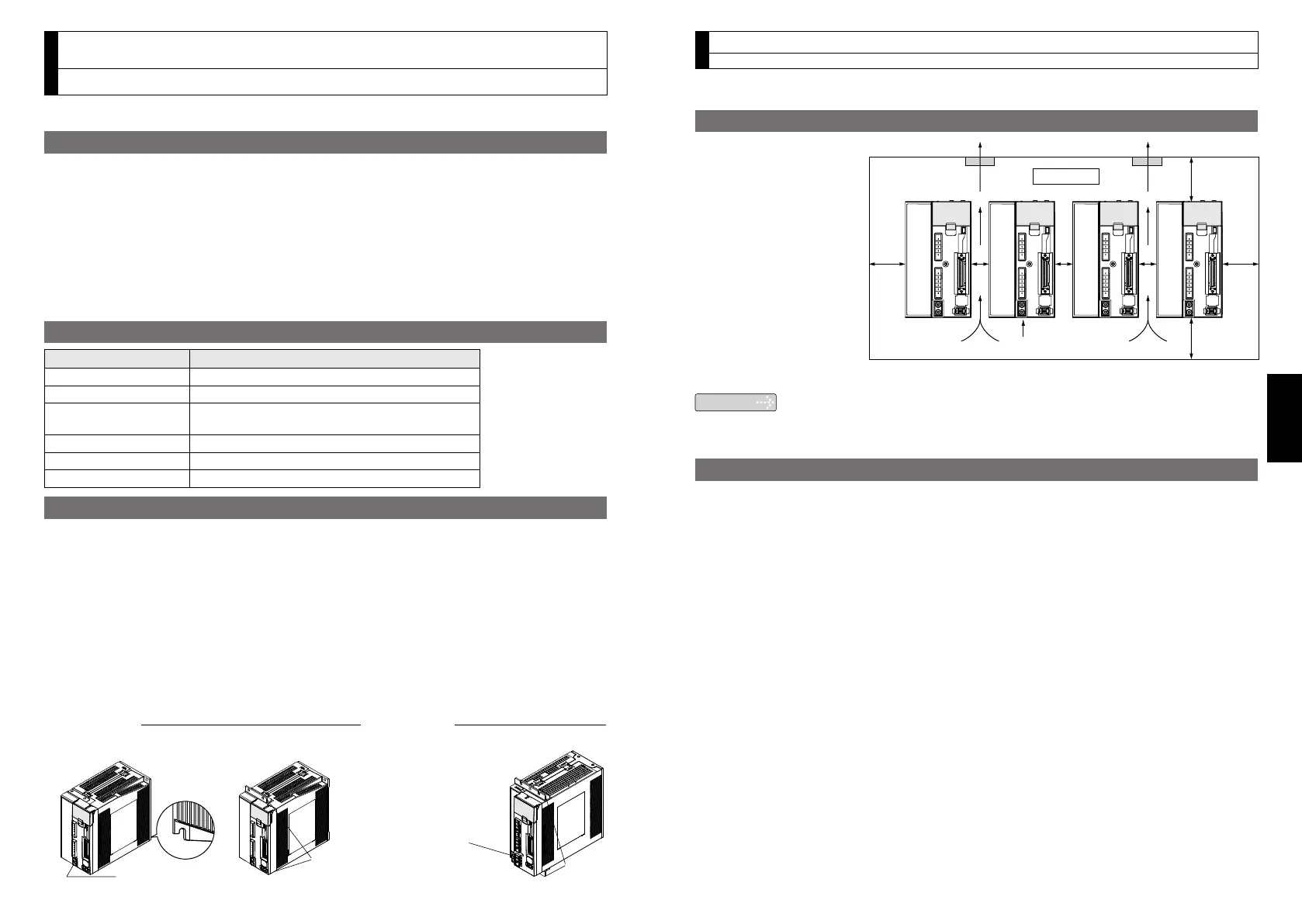

Mounting Direction and Spacing

•Reserveenoughsur-

roundingspacefor

effectivecooling.

•Installfanstoprovide

uniformdistribution

oftemperatureinthe

controlpanel.

•D/E/Fframeispro-

videdwithacooling

fanatthebottom.

•Observetheenviron-

mentalconditionsof

thecontrolpaneldescribedinthepreviouspage.

Fan Fan

100 mm

or more

100 mm

or more

40 mm

or

more

40 mm

or

more

10

mm

or

more

10

mm

or

more

10

mm

or

more

Direction of air flowing

from the internal

cooling fan (D/E/F frame)

Control panel

Note

Itisrecommendedtousetheconductivepaintwhenyoumakeyourown

mountingxture,orrepaintafterpeelingoffthepaintonthemachinefor

installingtheproducts,inordertomakenoisecountermeasure.

Caution on Installation

•Wehavebeenmakingthebestefforttoensurethehighestquality,however,applica-

tionofexceptionallylargeexternalnoisedisturbanceandstaticelectricity,orfailure

ininputpower,wiringandcomponentsmayresultinunexpectedaction.Itishighly

recommendedthatyoumakeafail-safedesignandsecurethesafetyintheopera-

tiverange.

•Ifstrandedwiresareusedasthecable,bunchtheconductorsofthecableusinga

rodterminalsoraroundterminals.

If stranded wires are used as they are, unexpected accidents such as an electric

shockandshortcircuitorinjurymayresult.(RefertoP.B19.“Wiringmethodtocon-

nector”.)

•Theremightbeachanceofsmokegenerationduetothefailureoftheseproducts.

Payanextraattentionwhenyouapplytheseproductsinacleanroomenvironment.

•Be suretoinstall ano-fuse breakerinthepowersupply.In addition,be sureto

groundthegroundingterminalorgroundwireprovided.

Iftheproductisgroundedinsufciently,notonlythedrivermaynotdeliveritsperfor-

mancesufciently,butalsosafetyhazardssuchasamalfunctionduetoaelectri-

cationoradisturbancemaybecaused.

•Ifelectricwiresareboundandrunthroughmetalduct,theycannotcarrytherated

current due to temperature rise. If they are forced to carry the rated current, they

mayburn.Whendeterminingsizeofthewire,checkthecurrentdecreasingcoef-

cientbyreferringtotheOperatingInstructions(Overall).

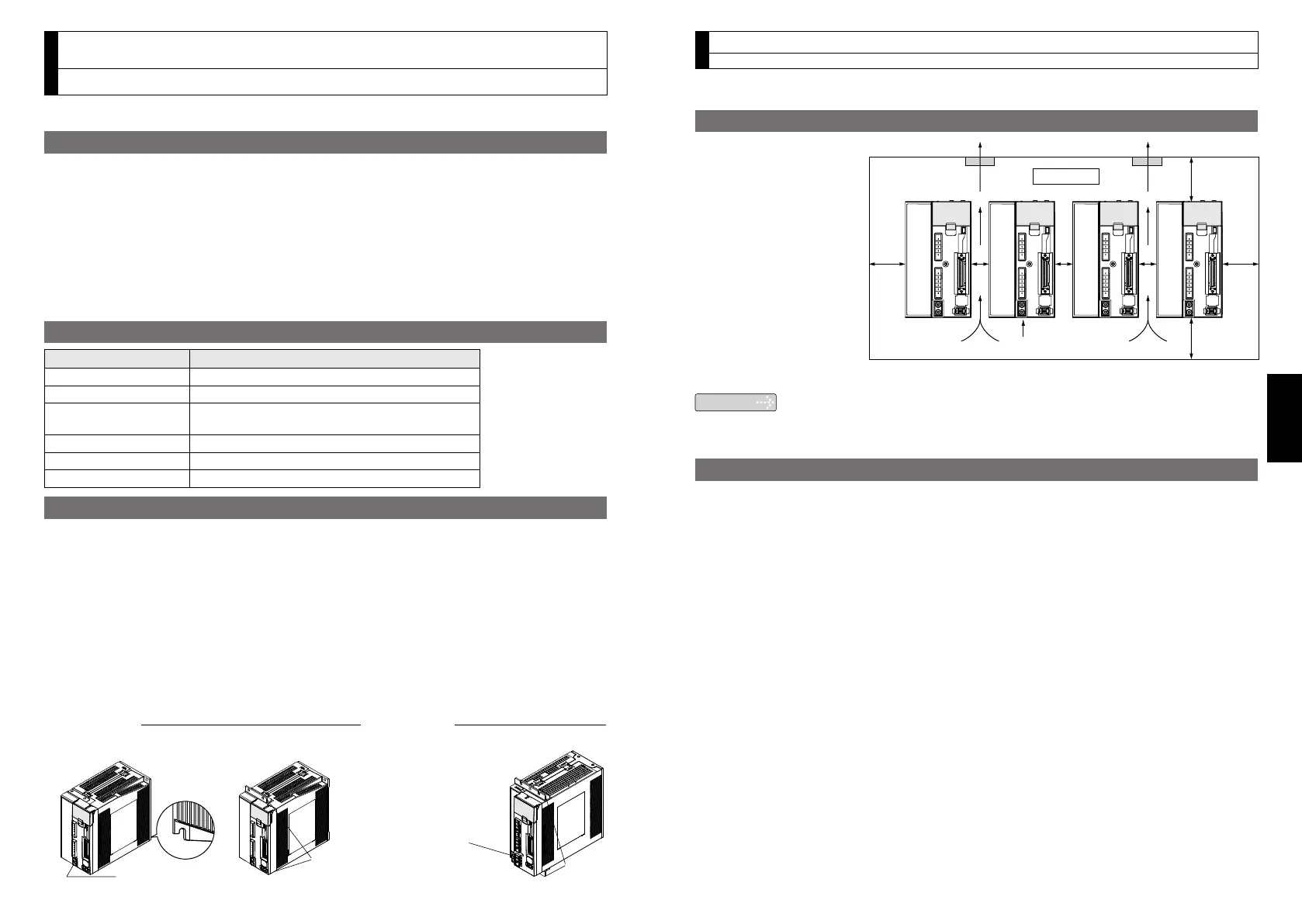

Basemount (Standard)

[Rear mount]

Frontmount

[Use mounting fixture]

Front or Basemount [Use mounting fixture]

Mounting fixture

(optional parts)

Mounting

fixture

(Attachment)

Fastening torque of earth

screws (M4) to be 0.7 to 0.8 N

•

m.

<E-frame>

Fastening torque of

earth screws (M4)

to be 0.7 to 0.8 N

•

m.

<F-frame>

Fastening torque of

earth screws (M5)

to be 1.4 to 1.6 N

•

m.

Loading...

Loading...