Parker Hannifin S.p.A. - Divisione S.B.C. “SPD” User’s Manual

45

PROCEDURE 2:

Pb94.4 actives this procedure. The parameters are shown in the table below:

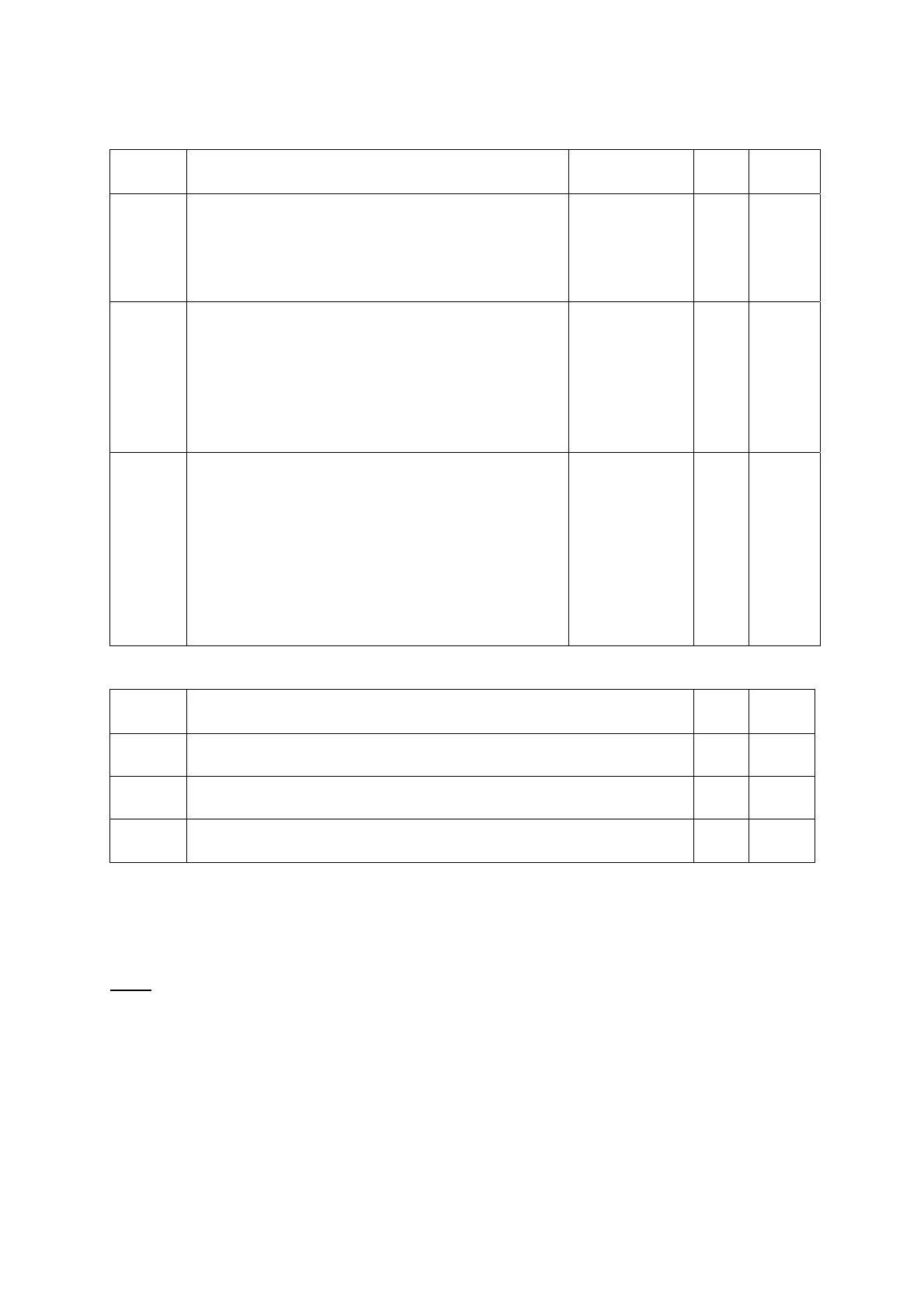

Par. Description Field/Unit Def. Type/

Note

Pb94.4

Command phasing 2. It’s necessary to disable

he software (Pb40.9=0); enable the hardware

(Pb41.5=1), and driver OK (Pr23=0).

The motor executes a vibration, the standing

depends to the type of the motor and to the load.

0

Pr 52

Pr 53

Used to normalise the number of encoder pulses

on the motor shaft revolutions to the standard

value 65536, through the following relation:

(Pr52/Pr53)*((encoder pulses/motor shaft

revolutions)*4)=65536

The sign determines the feedback (positive or

neg.)

±32767

1 R/W

M

Pr89 Status:

0 if positive result

2 if wrong enabling

5 if drive not ready (Pr23 ≠0 or open inrush)

6 Pr30 parameter calculated (frequency of

vibration) is different of 25 unit from starting

value

7 Pr30 parameter calculated (frequency of

vibration) exceeds 200 unit (max. value)

R

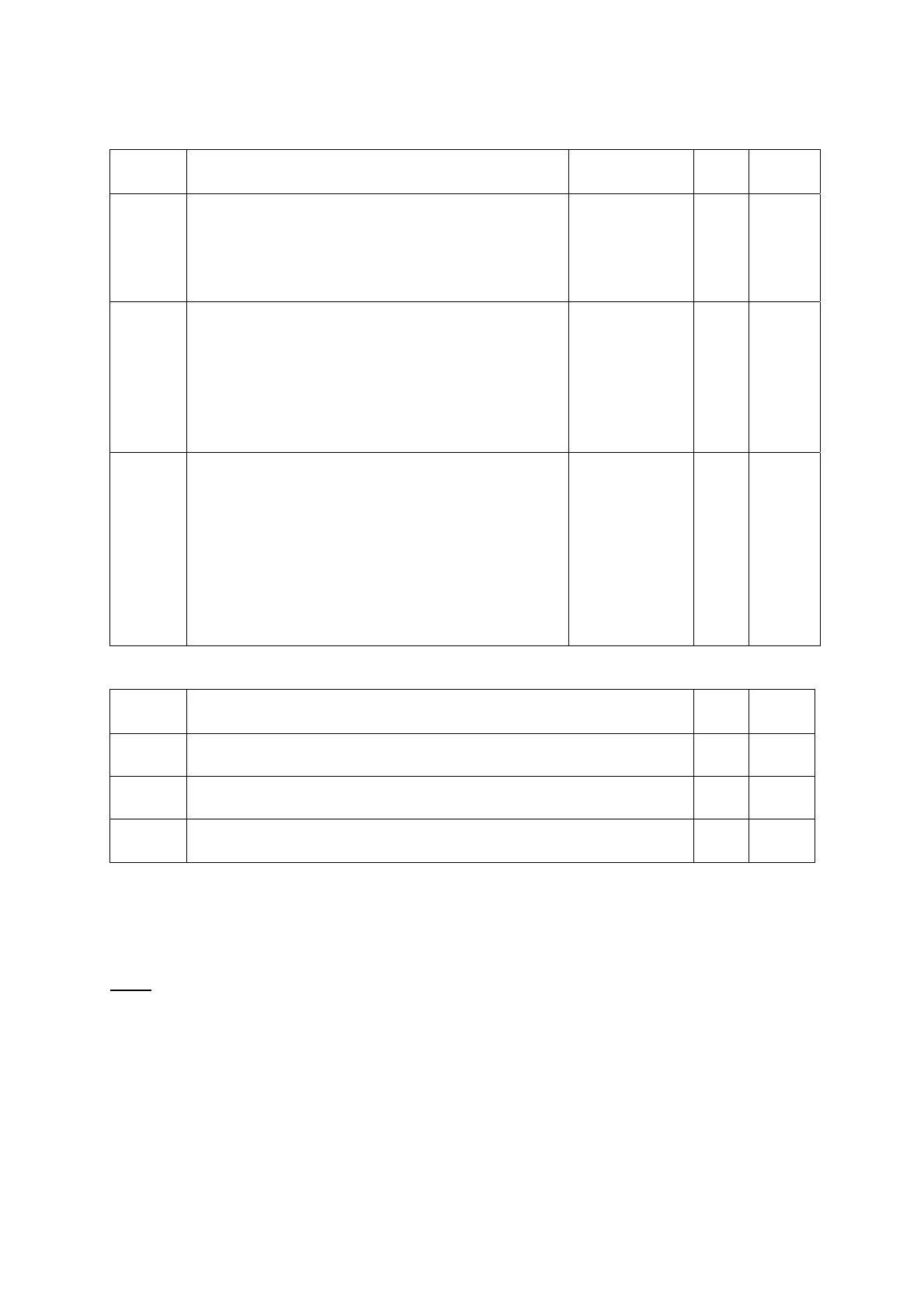

Par. Description Def. Type/

Note

Pb42.6 =1, select the feedback from encoder 0 M

Pb42.7 =0, select the feedback from encoder 0 M

Pb41.6 Phasing result :=1 if positive result of the procedure and

necessary condition for drive OK (Pb41.4)

0 R

The calculated value of Pr30 at the end of the procedure, if it is save, it permits at the

new start-up that the procedure starts from this value, and if the mechanical conditions

don’t change, makes only one vibration of standing fixed by Pr30.

N.B.: (*) during the phasing procedure the motor must be motionless, so if the motor is on

vertical axe, this system must be motionless without to use the brake.

(**) the encoder simulation can’t use zero encoder track as reference for reset the machine,

when the system uses a axis control and the FBK is a incremental encoder.

Loading...

Loading...