Parker Hannifin S.p.A. - Divisione S.B.C. “SPD” User’s Manual

69

10 Programming digital inputs/outputs

10.1 The pico-PLC

The internal pico-PLC is used to connect the external world (inputs/outputs) with the world of

the parameters of the drive. The PLC can be used to copy digital input to a binary parameter,

to copy a binary parameter to a digital output and to execute mathematical and Boolean

operations. The PLC program must be inserted as a list of instructions by using the keyboard

To change the instructions Pb99.13 must be set to zero. The default parameter setting

(Pb99.12) corresponds to a PLC program (see Appendix) written for a large number of

applications. In most cases it is not necessary to program the PLC itself.

The main features of the pico-PLC are:

Program steps 128

scanning time 6,144 ms

number of timers 2

number of instructions 15

stack depth 1

mathematical operations 16 / 32 bits

fast inputs 2 - (512 µs)

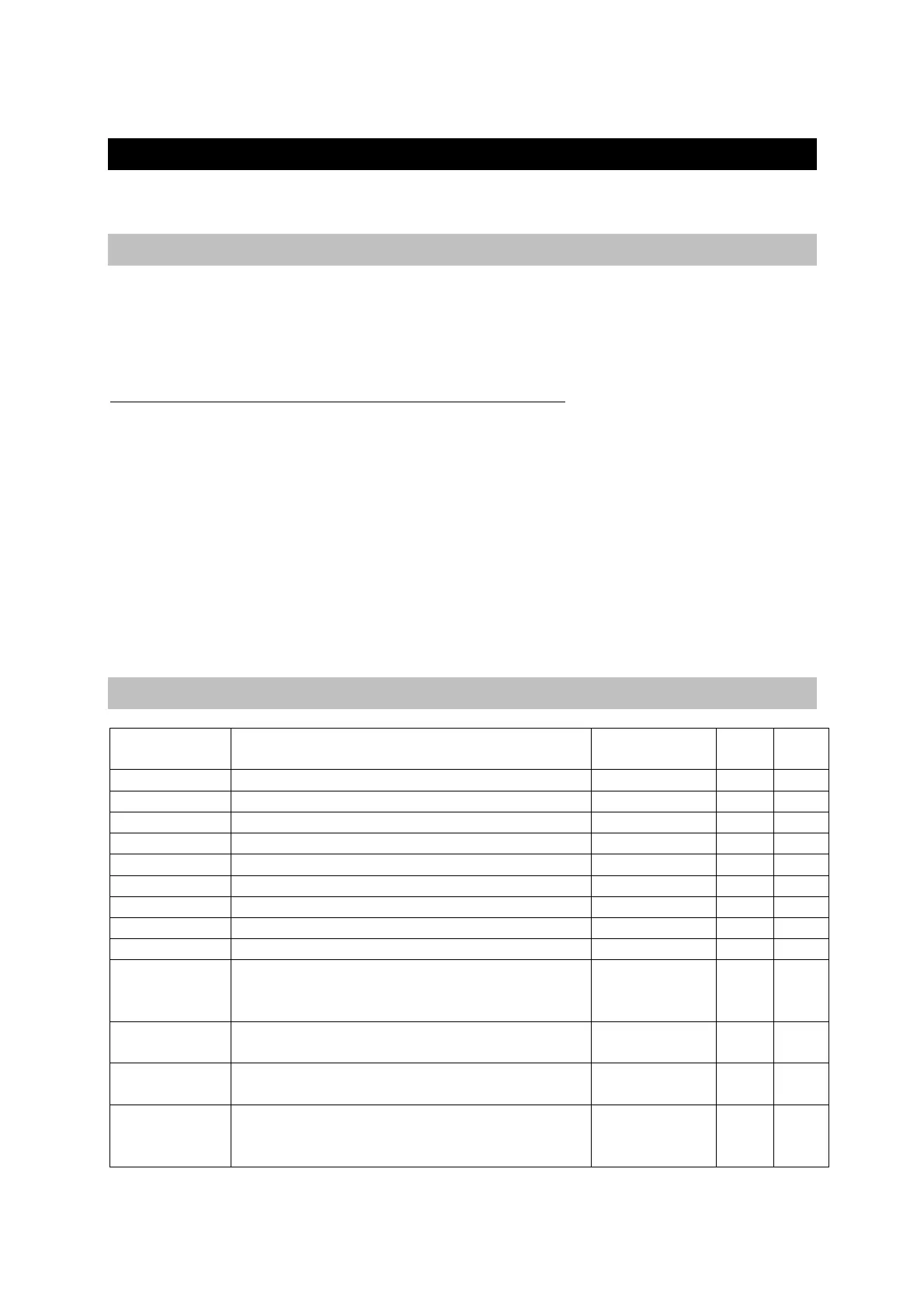

10.2 Decimal parameters PLC

Par. Description Field/Unit Def.

Type/

Notes

Pr 71 Constant value=-1 Double Word

-1 R/W

Pr 72 Constant value=0 Double Word 0

Pr 73 Constant value=1 Double Word 1

Pr 74 Constant value=2 Double Word 2

Pr 75 Constant value=10 Double Word

10

Pr76 Constant value= 100 Double Word

100

Pr 77 Constant value = 1000. Double word.

1000

Pr 78 Constant value = 1024. Double word.

1024

Pr 79 Constant value = 4096. Double word.

4096

Pr 80÷89

Free parameters.

Parameters that can be stored and

available to the user (word).

+/-32767 0 R/W

M

Pr 92 First timer of the PLC , if equal to zero,

Pb99.0=1.

0÷32767 0 R/W

Pr 93 Second timer of the PLC , if equal to

zero Pb99.1=1.

0÷32767

0 R/W

Pr151÷Pr163

Free parameters.

Parameters that can be stored and

available to the user (word).

+/-32767

0 R/W

M

Loading...

Loading...