460906 Rev. D 8/2020 MASTERTEMP

125 Pool and Spa Heater Installation and User’s Guide

17

Section 1. Installation Instructions

TESTING GAS LEAKS AND GAS PRESSURE

THE MASTERTEMP HEATER IS INTENDED FOR INSTALLATION WITH A METERED GAS PRESSURE REGULATOR.

Before operating the heater, the heater and its gas connections must be leak tested. DoNOTuseanopenametotest

forleaks. Test all gas connections for leaks with soapy water.

The gas valve must be completely disconnected from the gas supply piping system during any pressure testing of that

system at test pressures in excess of 6.0 kPa.

TESTING THE GAS PRESSURE THROUGH THE COMBINATION GAS CONTROL VALVE

WARNING

Risk of fire and explosion. Alteration, service, or maintenance of the Combination Gas Control Valve can lead to fire or explosion,

causing loss of life, personal injury, and/or property damage. DO NOT ATTEMPT TO ADJUST THE GAS CONTROL VALVE.

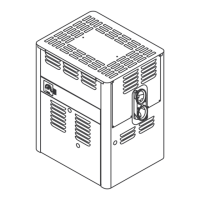

Figure 10.

1. Shut off the gas supply to the heater.

2. Loosen the small screw inside the pressure tap as shown in Figure 10.

3. Connect the manometer hose.

4. Open the gas supply to the heater.

5. Turn on the heater.

6. Take the gas pressure reading.

7. Turn off the heater.

8. Shut off the gas supply to the heater.

9. Disconnect the manometer hose.

10. Tighten the small screw inside the pressure tap.

Description Type Gas Supply Pressure

Natural Gas

1.0 kPa 6.0 Kpa

Propane Gas

2.5 kPa 6.0 pKa

NOTE: The minimum value approved for input adjustment. Do not exceed the

maximum supply pressure.

All readings must be taken while heater is operating. Any adjustments or

readings made while heater is off will result in performance problems.

INLET GAS PRESSURE REQUIREMENTS

CAUTION! This appliance is equipped with an unconventional gas control valve that is factory set with a manifold

pressure of 11 ± 5 kPa. Installation or service must be performed by a qualied installer, service agency, or the gas

supplier. If this control valve is replaced, it must be replaced with an identical control. The combination gas valve

incorporates dual shut-off valves and a negative-pressure regulator. For proper operation, the regulated pressure at the

outlet manifold of the valve must be 11 ± 5 kPa below the reference pressure at the blower mixer inlet, and the gas

valve ‘VENT’ tap must be connected to the end cap air orice as shown in Figure 9 (page 16).DONOTattemptto

adjustthegasinputbyadjustingtheregulatorsetting.Thecorrectgasregulatorsettingisrequiredtomaintain

propercombustionandmustNOTbealtered.

Lightly loosen the

small screw inside the pressure tap,

and attach/connect the manometer hose.

Table 2.

Loading...

Loading...