6

Setting:

Adjustment:

.1

.2

.3

.4

.5

.6

.7

.8

Adjusting

the

needle

throw

When the

needle

bar

rises from the bottom position on the right of its throw to t.d.c. (pin

in

hole

2) it

must

not

move

to

the

side

when

the

stitch width

lever

is

moved

to

and

fro.

coAmm

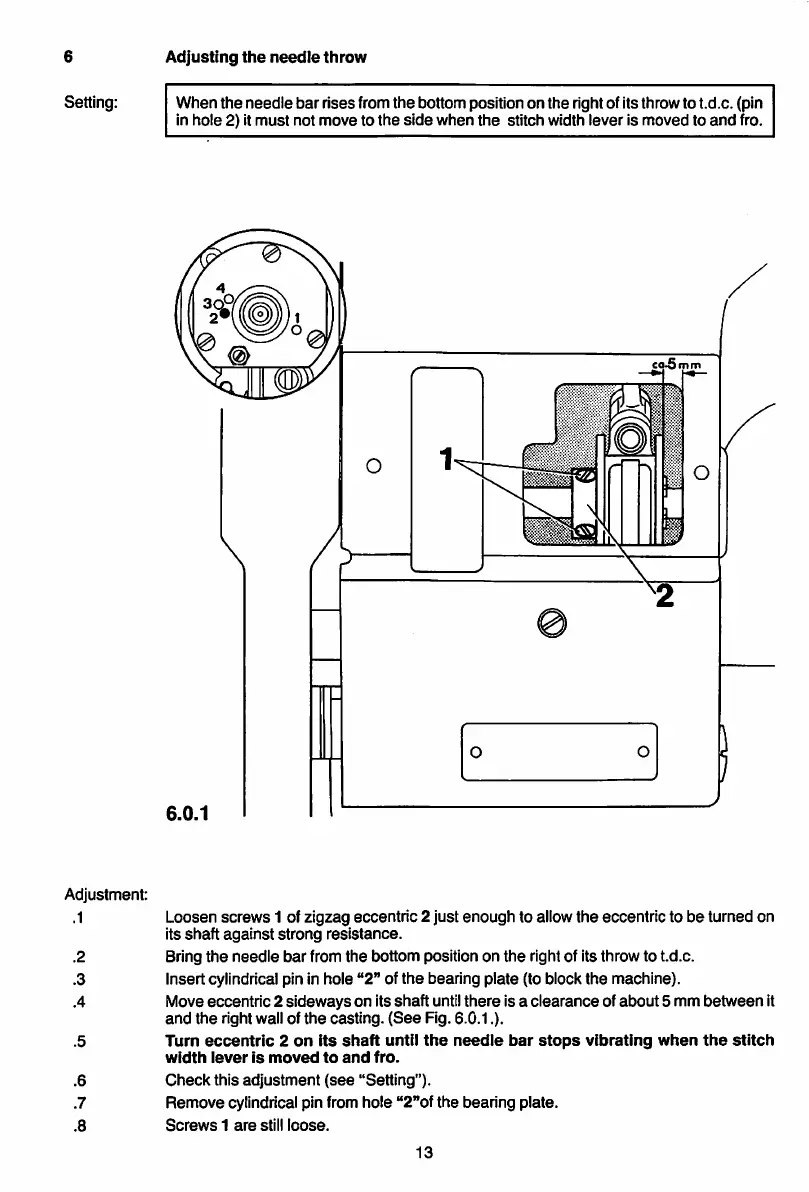

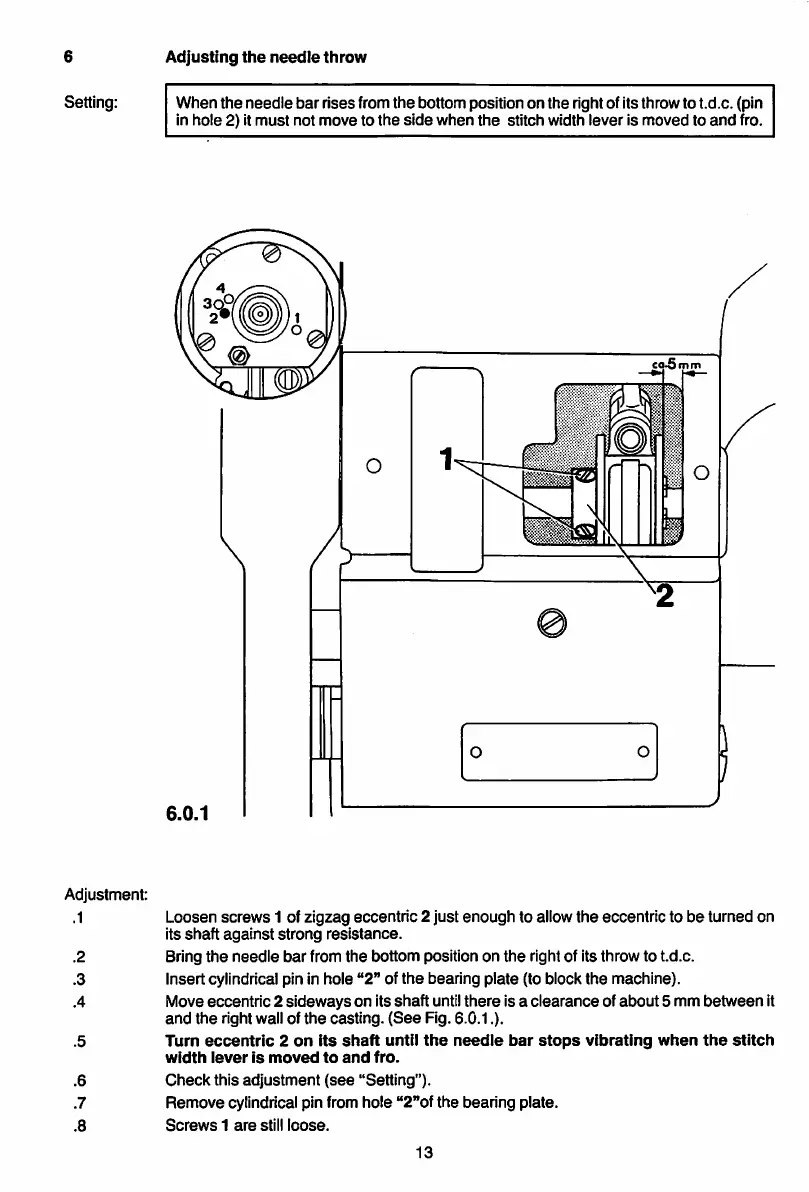

6.0.1

Loosen screws 1 of zigzag eccentric 2 just enough to allowthe eccentric to be turned on

its

shaft

against

strong

resistance.

Bring

the

needle

bar

from the bottom position on

the

right of its throw to t.d.c.

Insert cylindrical pin in hole "2" of the bearing plate (to block the machine).

Move eccentric 2 sidewayson its shaft untilthere is a clearance ofabout 5 mm betweenit

and

the

right wall of the casting.

(See

Fig. 8.0.1.).

Turn

eccentric

2

on

its

shaft

until

the

needle

bar

stops

vibrating

when

the

stitch

width

lever

is

moved

to

and

fro.

Check

this

adjustment

(see

"Setting").

Remove

cylindrical pin from hole "2"of the bearing plate.

Screws

1

are

still

loose.

13

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

Loading...

Loading...