14

Setting:

Adjustment:

14.1

.2

.3

.4

.5

Adjusting

the

hook

bearing

bracket

The

hook

shaft

must

contact

both

the

vertical

and

horlzontai

surfaces

of

the

hook

bearing

bracket

gauge.

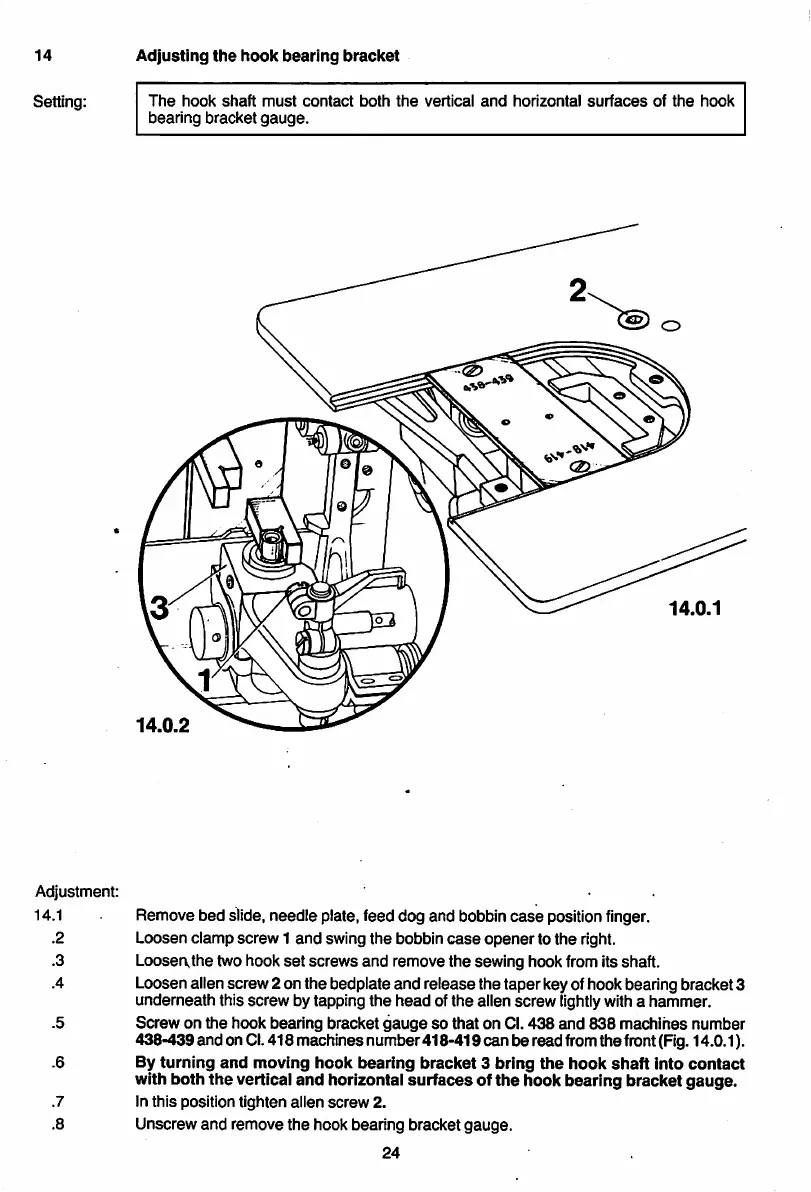

14.0.1

14.0.2

Remove bed slide, needle plate, feed dog and bobbin

case

position finger.

Loosen clamp screw1

and

swing the bobbin

case

opener

to the right.

Loosen,the two hook

set

screws and remove the sewing hook from its shaft.

Loosen alien screw 2 on the bedplate and releasethe taper keyofhook bearing bracket 3

underneath thisscrew bytapping the head ofthe alien screw

lightly

witha hammer.

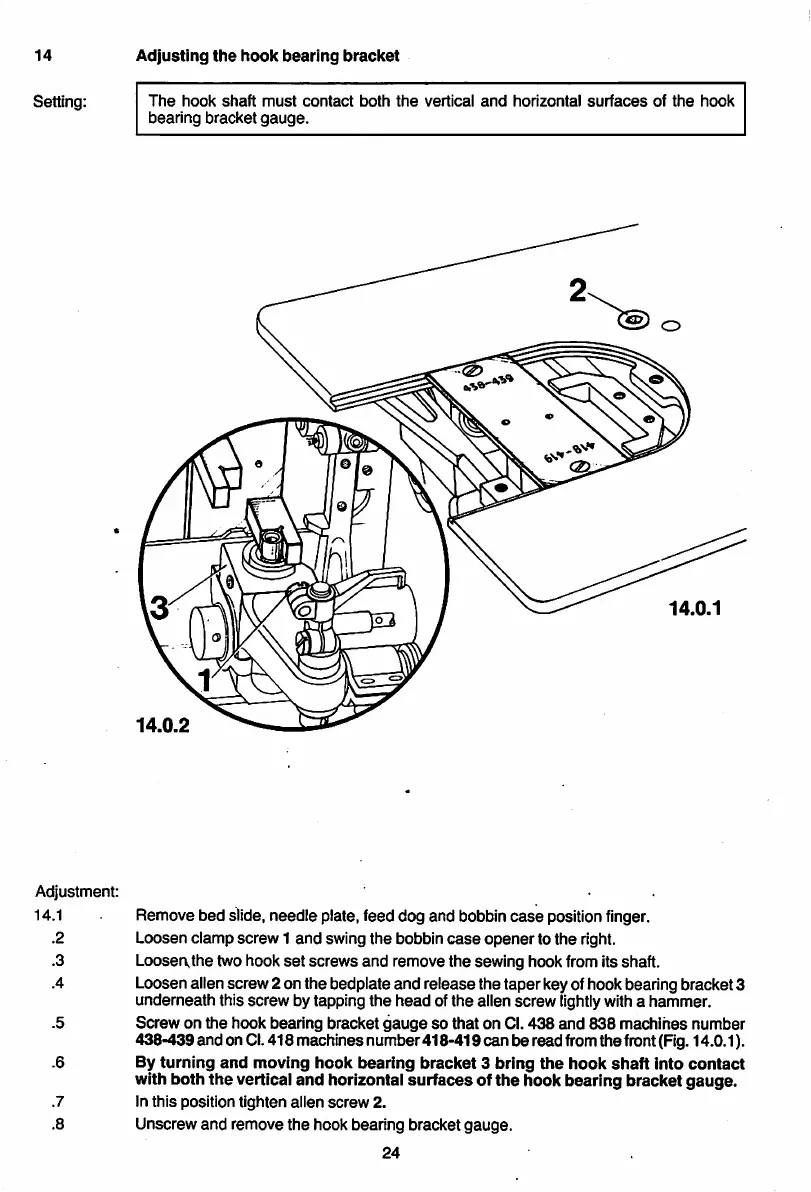

Screw

on

the

hook bearing bracket

gauge

so

that on Ci.

438

and

838

machines

number

438-439and on Ci.418 machinesnumber418-419can be read fromthe front(Fig.14.0.1).

By

turning

and

moving

hook

bearing

bracket

3

bring

the

hook

shaft

into

contact

with both

the

vertical

and

horizontal

surfaces

of

the

hook bearing bracket gauge.

In this position tighten alien

screw

2.

Unscrew

and

remove the hook bearing bracket gauge.

24

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

Loading...

Loading...