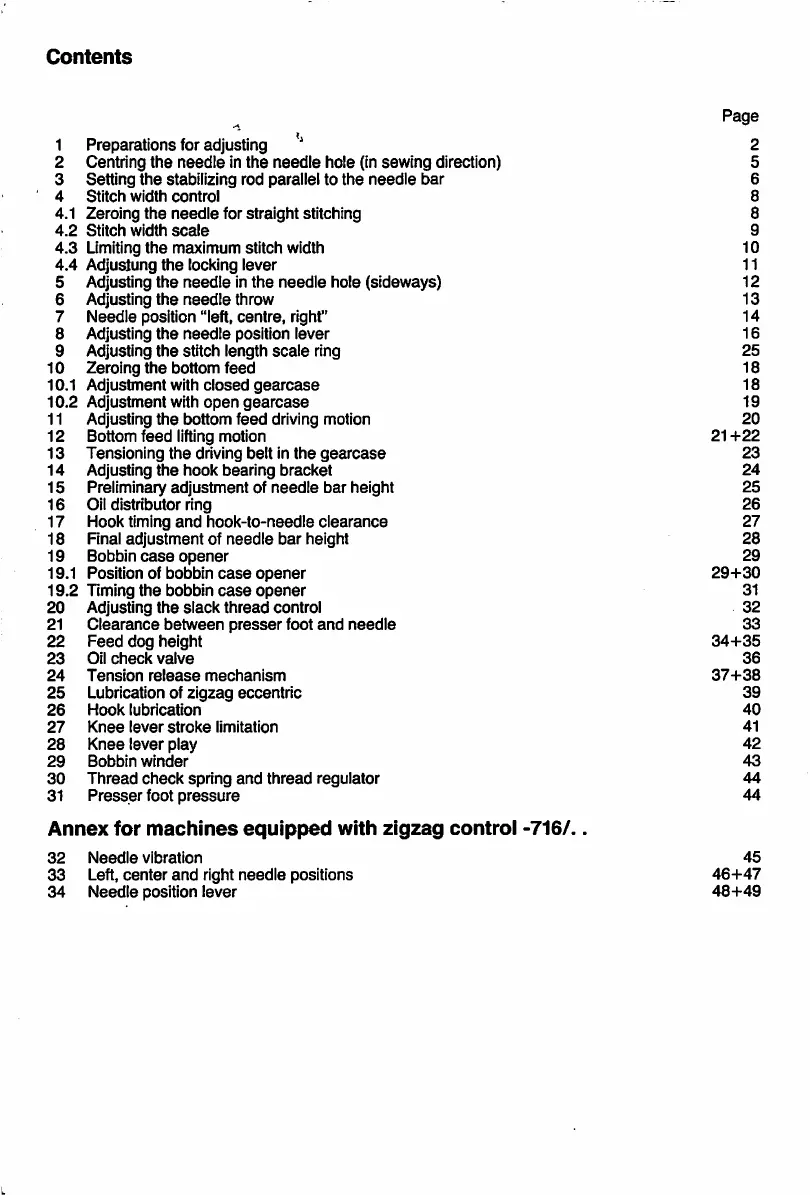

Contents

Page

1

Preparations for adjusting

2

2 Centring the needle in

the

needle hole (in sewing direction) 5

3

Setting

the

stabilizing rod parallel to the

needle

bar

6

4

Stitch

width

control

8

4.1

Zeroing

the

needle

for straight stitching 8

4.2

Stitch

width

scale

9

4.3

Limiting

the

maximum stitch width

10

4.4

Adjustung

the

locking

lever

11

5

Adjusting

the

needle

in

the

needle

hole (sideways)

12

6

Adjusting

the

needle

throw

13

7

Needle position "left, centre, right"

14

8 Adjusting

the

needle

position lever

16

9

Adjusting

the

stitch length

scale

ring

25

10

Zeroing

the

bottom

feed

18

10.1

Adjustment with

closed

gearcase

18

10.2

Adjustment

with

open

gearcase

19

11

Adjusting

the

bottom

feed

driving motion

20

12

Bottom

feed

liftingmotion

21+22

13

Tensloning

the

driving belt in

the

gearcase

23

14

Adjusting

the

hook bearing bracket

24

15

Preliminary adjustment of

needle

bar height

25

16

Oil distributor ring

26

17

Hook timing

and

hook-to-needle

clearance

27

18

Final

adjustment

of

needle

bar

height

28

19

Bobbin

case

opener

29

19.1

Position of bobbin

case

opener

29+30

19.2

Timing

the

bobbin

case

opener

31

20

Adjusting

the

slack

thread

control

32

21

Clearance

between

presser

foot

and

needle

33

22

Feed

dog

height

34+35

23

Oil

check

valve

36

24

Tension

release

mechanism

37+38

25

Lubrication of

zigzag

eccentric

39

26

Hook

lubrication

40

27

Knee

lever

stroke

limitation

41

28

Knee lever play

42

29

Bobbin

winder

43

30

Thread

check

spring

and

thread

regulator

44

31

Presser

foot

pressure

44

Annex

for

machines

equipped

with

zigzag

control

-716/..

32

Needle

vibration

45

33 Left,

center

and

right

needle

positions

46+47

34

Needle

position

lever

48+49

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

Loading...

Loading...