16 Oil

distributor

ring

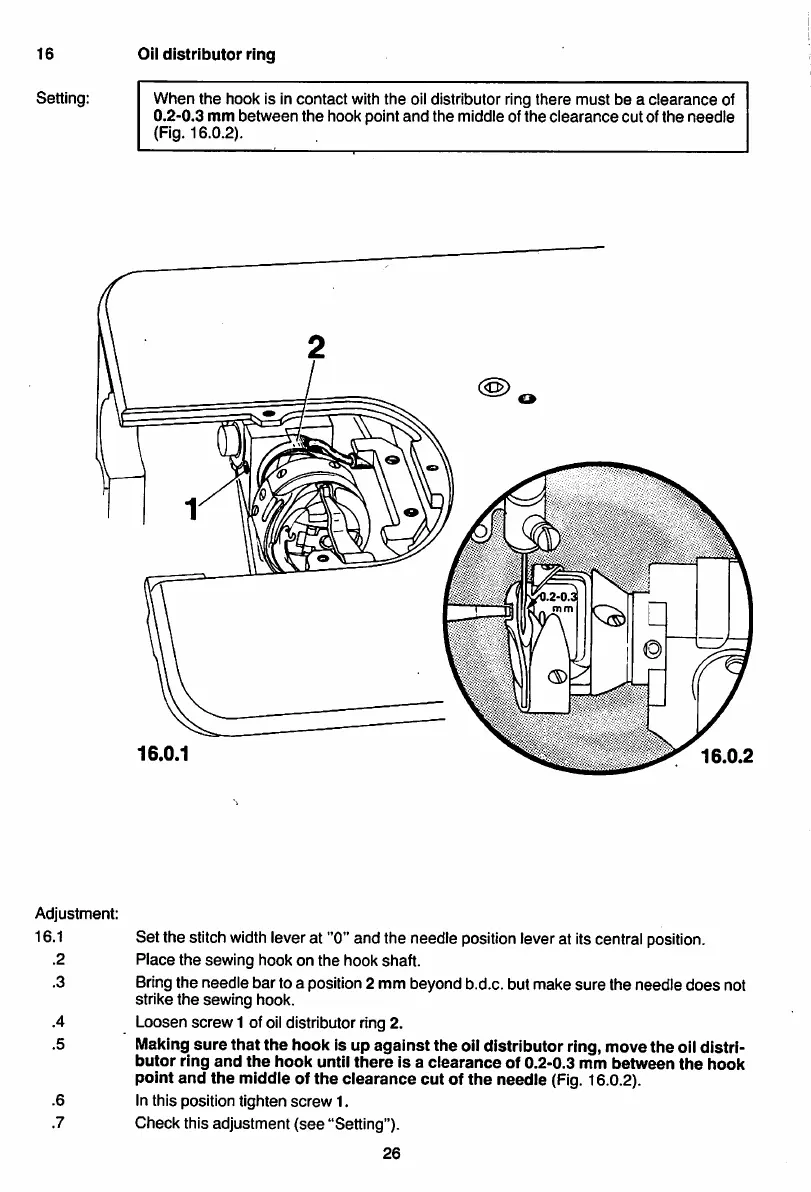

Setting: When the hook is in contact with the oildistributor ring there must be a clearance of

0.2-0.3 mm

between

the hook point

and

the middle ofthe

clearance

cut of the

needle

(Fig. 16.0.2).

Adjustment:

16.1

.2

.3

.4

.5

.6

.7

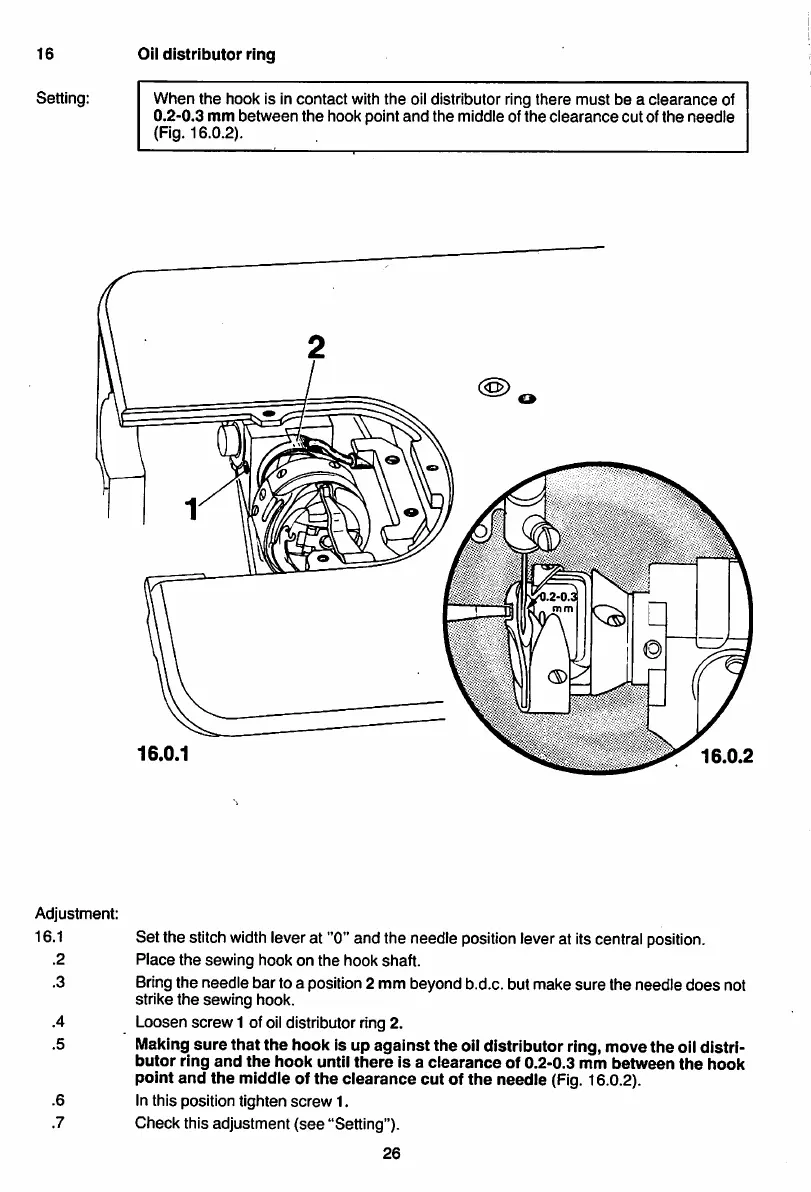

16.0.1

16.0.2

Set the stitch

width

lever at "0" and the needle positionleverat itscentral position.

Place

the sewing hook on the hook shaft.

Bringthe needle bar to a position 2 mm beyond b.d.c. but make sure the needle

does

not

strike

the

sewing hook.

Loosen

screw

1 of oildistributor ring 2.

Making

sure

that

the

hook is up

against

the

oil distributor ring, move the oil distri

butor

ring

and

the

hook

until

there

is

a

clearance

of

0.2-0.3

mm

between

the

hook

point and the middle of the clearance cut of the needle

(Fig.

16.0.2).

In this position tighten

screw

1.

Check this adjustment

(see

"Setting").

26

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

Loading...

Loading...