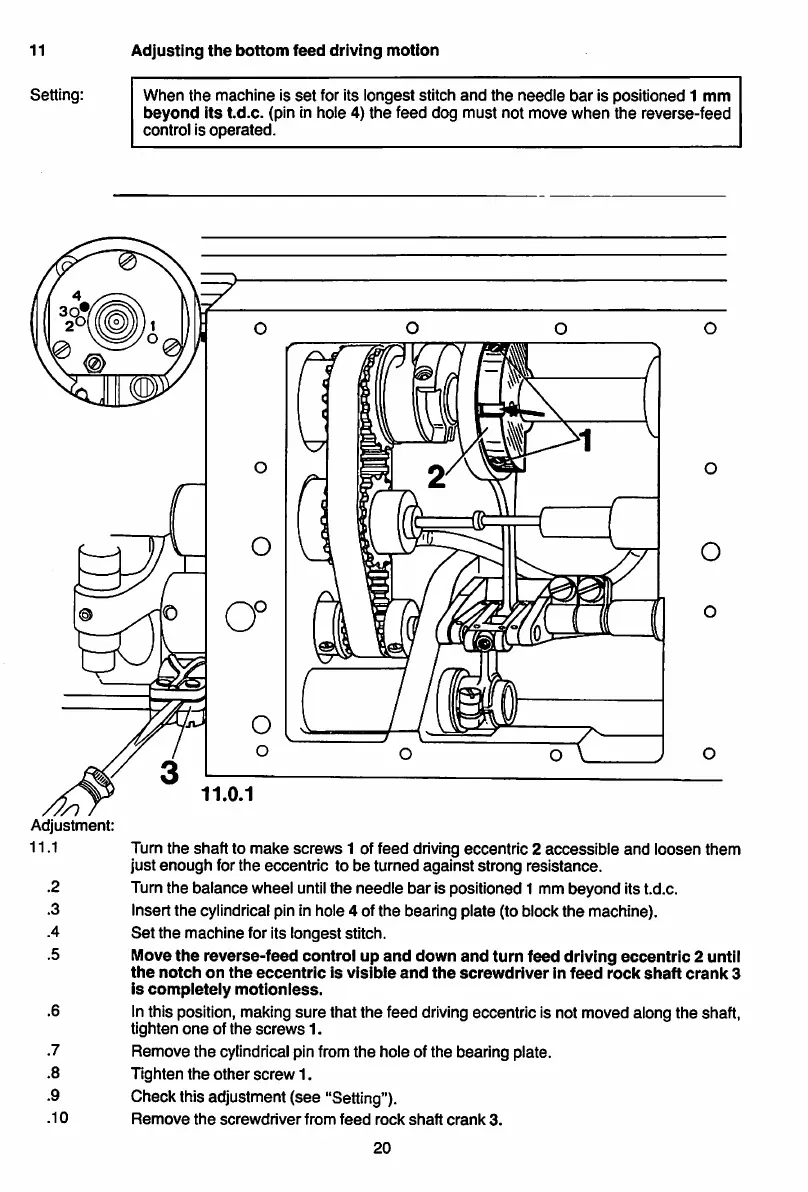

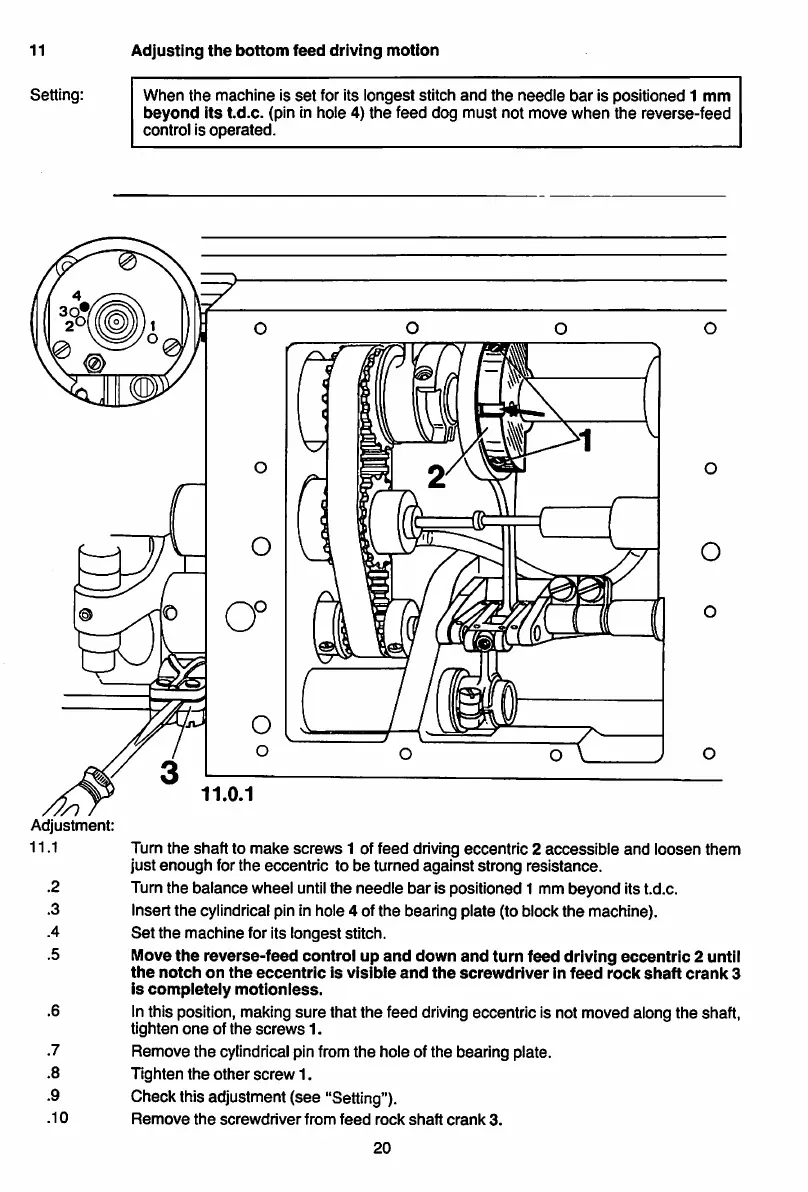

11

Adjusting

the

bottom

feed

driving

motion

Setting: When the machine is

set

for its longest stitch

and

the

needle

bar

is positioned 1 mm

beyond

its

t.d.c.

(pin in hole 4)

the

feed dog

must

not move

when

the

reverse-feed

control is

operated.

11.0.1

Adjustment:

11.1 Turn the shaft to

make

screws 1 of feed driving eccentric 2 accessible and loosen them

just enough forthe eccentric to be turned against strong resistance.

.2 Turnthe balance wheel untilthe needle bar is positioned 1 mmbeyond its t.d.c.

.3 Insertthe cylindrical pininhole4 ofthe bearing plate (to blockthe machine).

.4

Set

the machine for its longeststitch.

.5 Move

the

reverse-feed control up

and

down

and

turn feed driving eccentric 2 until

the

notch

on

the

eccentric

is

visible

and

the

screwdriver

in

feed

rock

shaft

crank

3

is

completely

motionless.

.6 Inthis position,makingsure that the feed

driving

eccentric is not moved along the shaft,

tighten

one

of

the

screws

1.

.7 Remove the cylindricalpinfromthe hole of the bearing plate.

.8 Tighten

the

other

screw

1.

.9 Checkthis

adjustment

(see

"Setting").

-10

Remove

the

screwdriver

from

feed

rock

shaft

crank

3.

20

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

Loading...

Loading...