Bobbin

winder

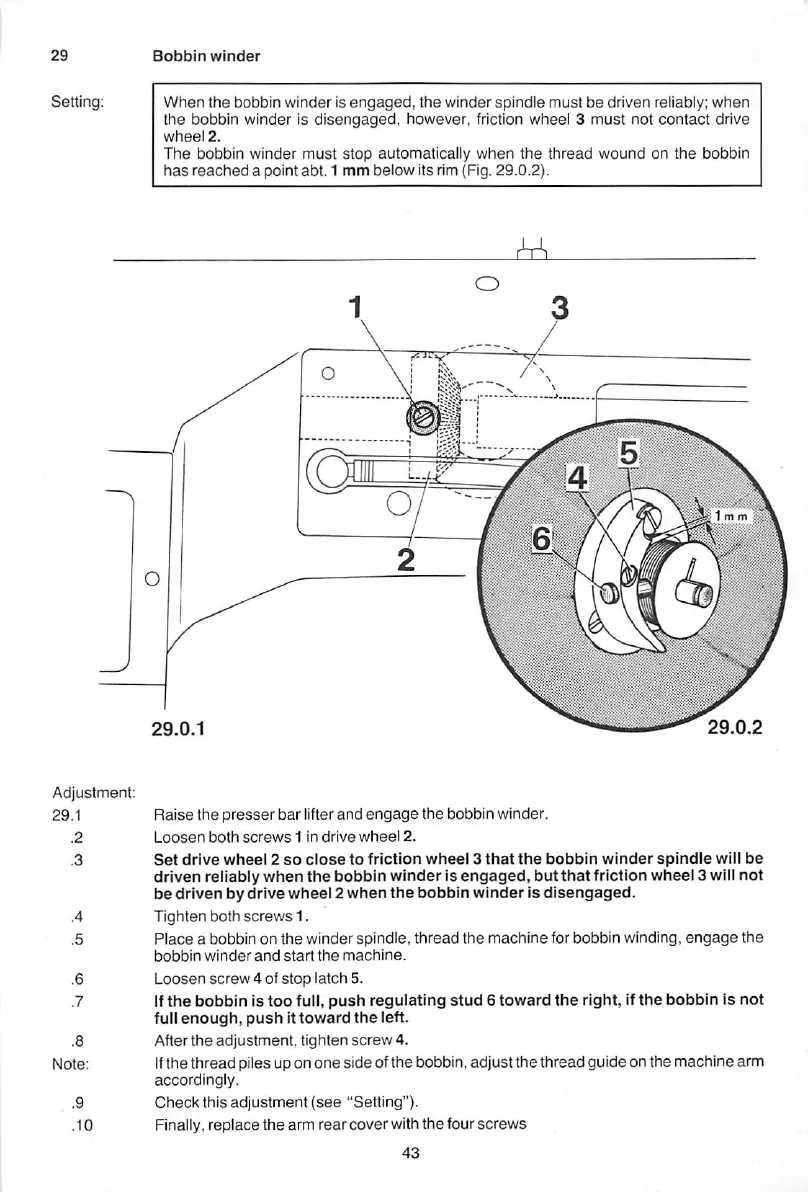

When

the

bobbin winder is

engaged,

the

winder spindle must be driven reliably;

when

the bobbin winder is

disengaged,

however, friction wheel 3

must

not

contact

drive

wheel

2.

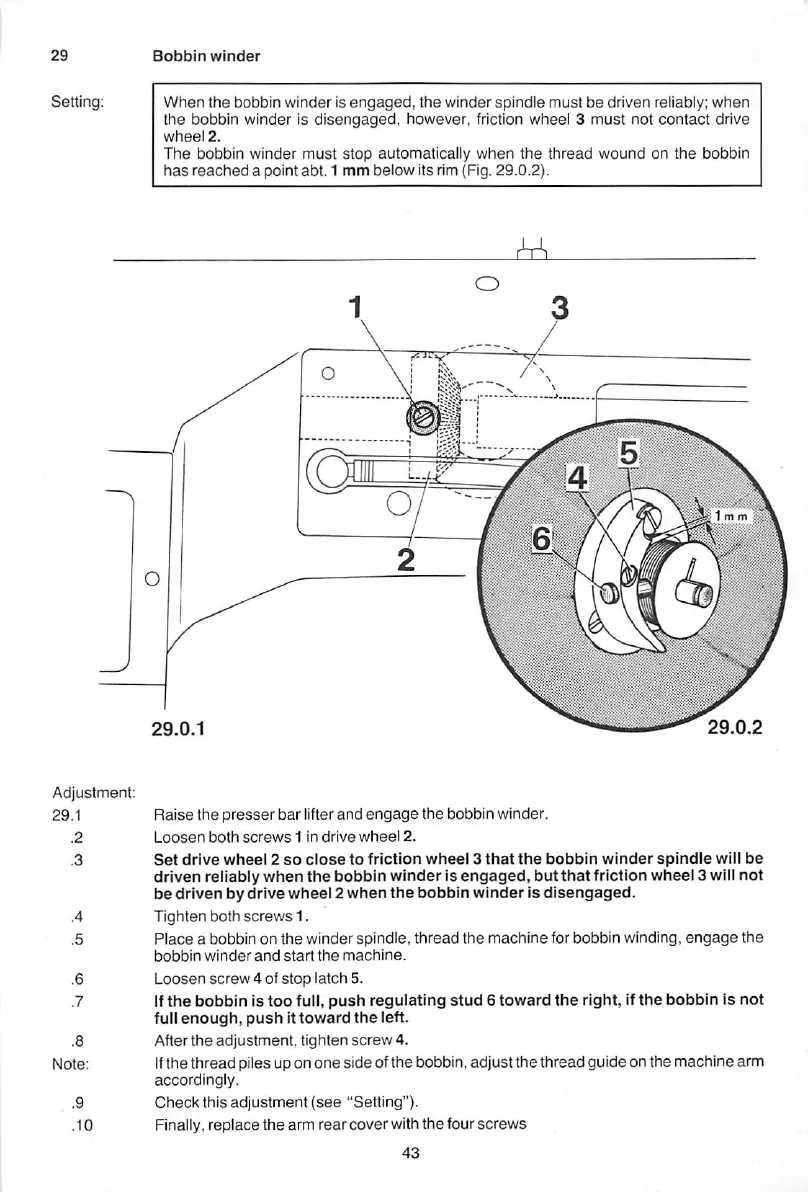

The

bobbin winder

must

stop

automatically

when

the

thread

wound on

the

bobbin

has

reached

a point abt. 1 mm below its rim(Fig. 29.0.2).

29.0.2

Raise

the

presser

bar

lifterand

engage

the bobbin winder.

Loosen

both

screws

1 in

drive

wheel

2.

Set

drive

wheel

2

so

close

to

friction

wheel

3

that

the

bobbin

winder

spindle

will

be

driven

reliably

when

the

bobbin

winder

is

engaged,

but

that

friction wheel 3 will

not

be driven by drive wheel 2

when

the

bobbin

winder

is

disengaged.

Tighten

both

screws

1.

Place a bobbin on the winder spindle, thread the machine forbobbin winding,

engage

the

bobbin

winder

and

start

the

machine.

Loosen

screw

4 of

stop

latch 5.

If

the

bobbin

is

too

full,

push

regulating

stud

6

toward

the

right, if

the

bobbin

Is

not

full

enough,

push

it

toward

the

left.

After

the

adjustment,

tighten

screw

4.

If

the

thread

piles up on

one

side

of

the

bobbin, adjust the

thread

guide

on the

machine

arm

accordingly.

Check

this

adjustment

{see

"Setting").

Finally, replace the arm

rear

cover

with

the

four

screws

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

Loading...

Loading...