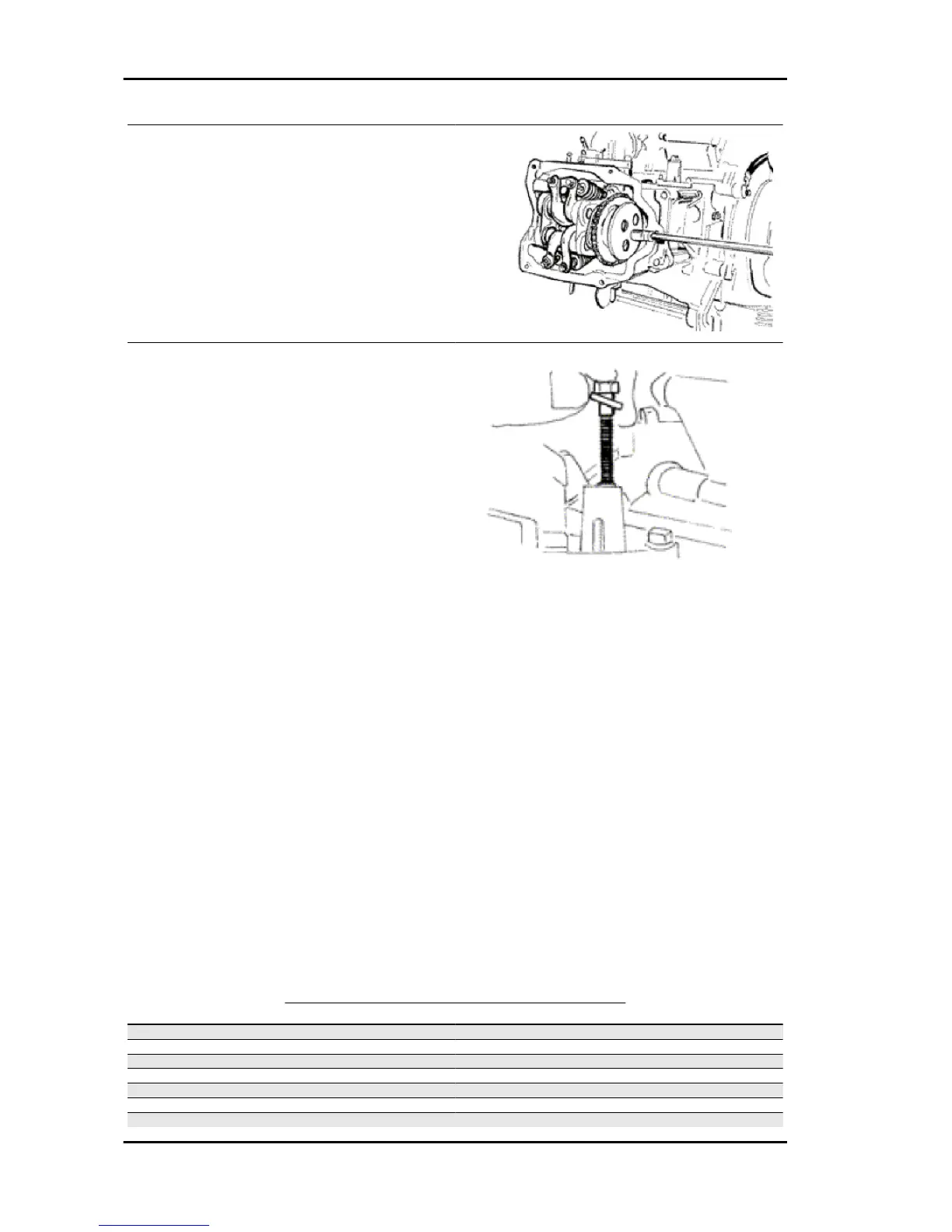

Assemble the limiting bell using the counterweight

fixing screw as a reference.

- Tighten the clamping screw to the prescribed tor-

que.

Locking torques (N*m)

Limiting bell screw 11 ÷ 15 Nm

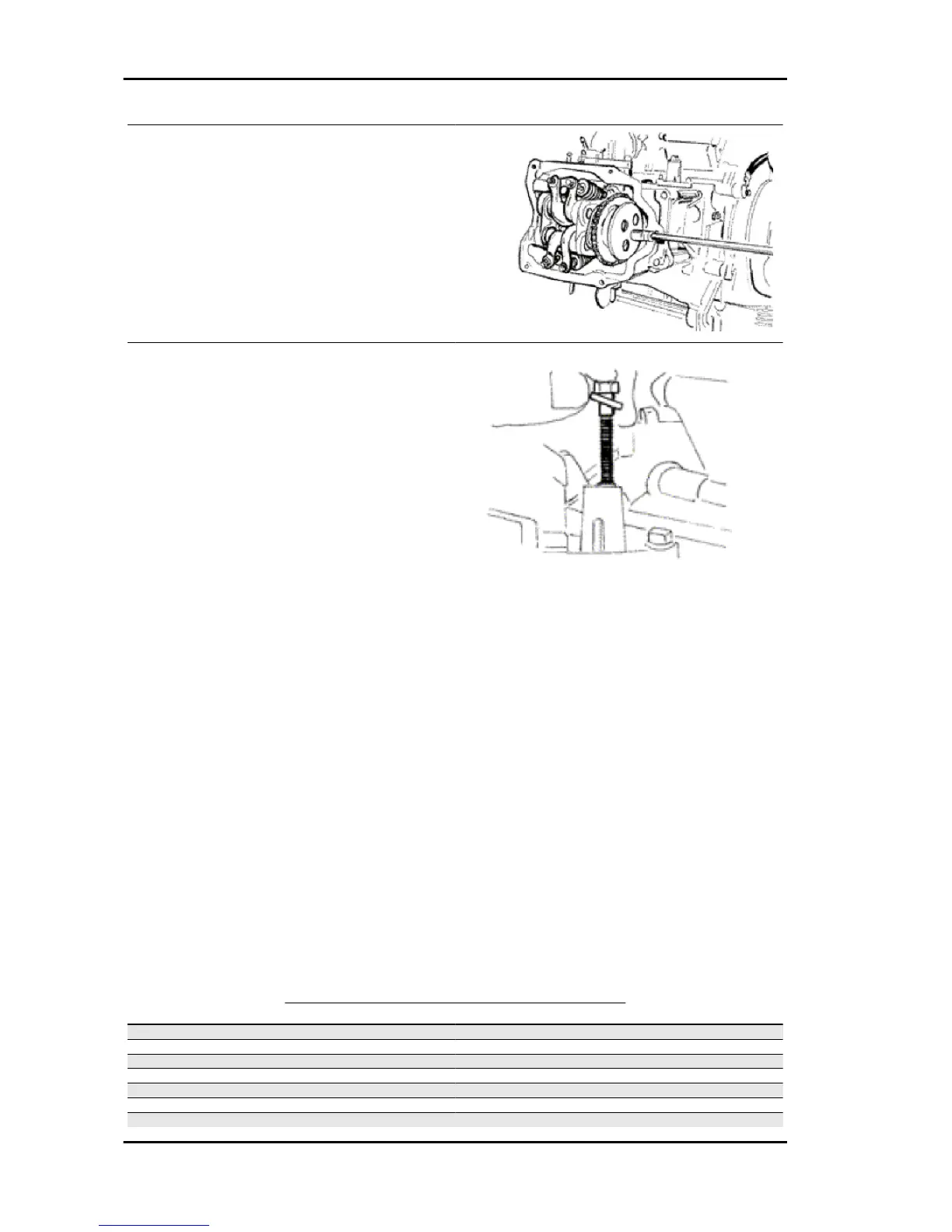

Set the tensioner cursor to the rest position.

- Fit the chain tensioner on the cylinder, using a

new gasket, and tight the two screws to the pre-

scribed torque.

Insert the chain tensioning screw, together with the

spring and washer, tightening it to the prescribed

torque.

Locking torques (N*m)

Tensioner screws 11 ÷ 13 Tensioner cover 5 ÷ 6

Nm

Adjust valve clearance

- Fit the spark plug.

Electrode distance 0.8 mm

Locking torques (N*m)

Spark plug 12 ÷ 14

Refit the cylinder head cover, tightening the 5 screws to the prescribed torque. Make sure the gasket

is positioned properly.

Remove the flywheel cover completely as already described in the flywheel chapter.

- Reassemble the oil pump control, the chain compartment cover, the by-pass and the oil sump as

described in the lubrication chapter.

- Reassemble the driving pulley, the belt and the transmission cover as described in the transmission

chapter.

Locking torques (N*m)

Tappet cover screws 6 - 7 Nm

TIMING SYSTEM COMPONENTS ASSEMBLY

Name

Torque in Nm

Tappet cover screws 6 - 7 Nm

Spark plug 12 ÷ 14

Tensioner cover 5 ÷ 6 Nm

Tensioner screws 11 ÷ 13

Limiting bell screw 11 ÷ 15 Nm

Counterweight screw 7 ÷ 8.5

Plate screws 4 ÷ 6 Nm

Engine Runner 125 - 200

ENG - 170

Loading...

Loading...