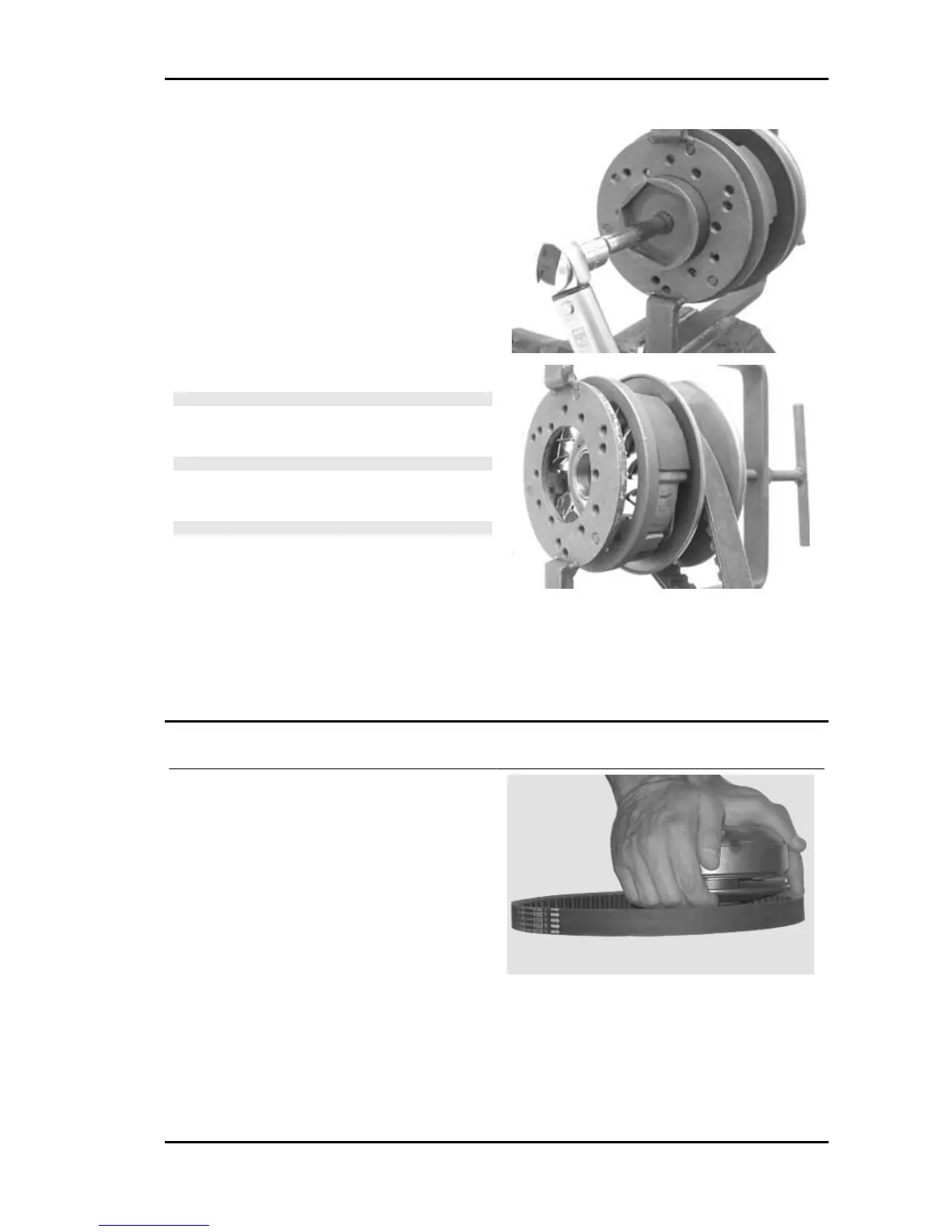

- Loosen the tool clamp and insert the belt accord-

ing to its direction of rotation.

- Lock the driven pulley again using the appropri-

ate tool.

- Preload the clutch contrast spring with a traction/

rotation combined action until it reaches the pul-

leys maximum opening and place the belt on the

minimum rolling diameter.

- Remove the driven pulley /belt assembly from the

tool.

N.B.

FOR DESIGN REASONS, THE NUT IS SLIGHTLY ASYM-

METRIC; THE FLATTEST SURFACE SHOULD BE MOUN-

TED IN CONTACT WITH THE CLUTCH.

N.B.

DURING THE SPRING PRELOADING PHASE, BE CARE-

FUL NOT TO DAMAGE THE PLASTIC SPRING STOP AND

THE BUSHING THREADING.

N.B.

AN EXCESSIVE QUANTITY CAN DAMAGE THE CLUTCH

OPERATION.

Specific tooling

020444Y011 adapter ring

020444Y009 46x55 Wrench

Locking torques (N*m)

Clutch unit nut on driven pulley 55 ÷ 60

Refitting the driven pulley

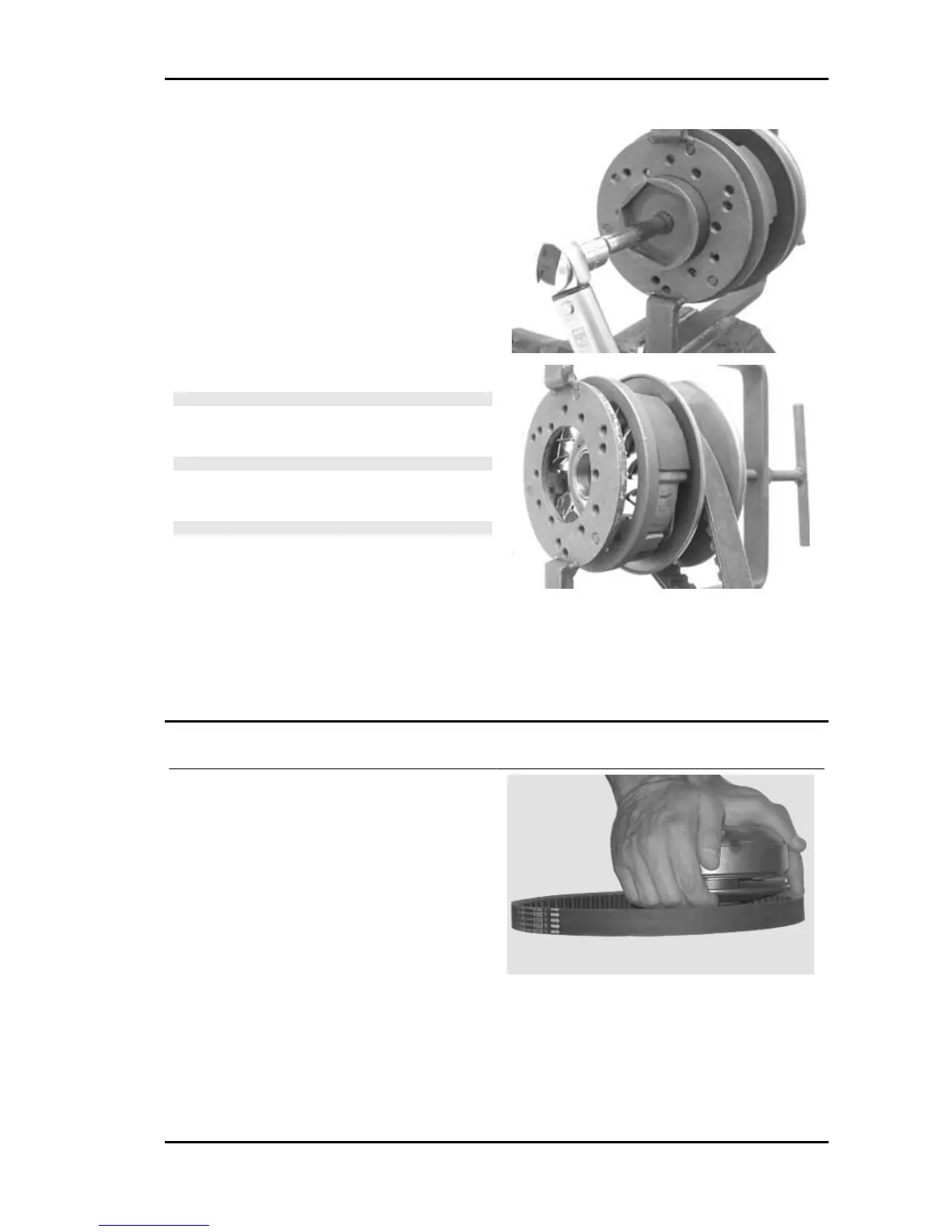

- Place the driven pulley with clutch bell on the

work table.

- With your hands compress the mobile pulley

while introducing the driving belt fully between the

pulleys.

This operation is necessary so that the belt

does not interfere with the correct assembly of

the moving driving pulley and loosen the nut

on the crankshaft.

- Refit the whole driven pulley on its shaft.

Runner 125 - 200 Engine

ENG - 135

Loading...

Loading...